Preparation method of plugging composite material polyurethane elastomer used in coal mines

A polyurethane elastomer and composite material technology, which is applied in the field of synthesis of organic + inorganic compound elastomer composite materials, can solve problems such as poor adhesion, secondary cracks, and high prices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

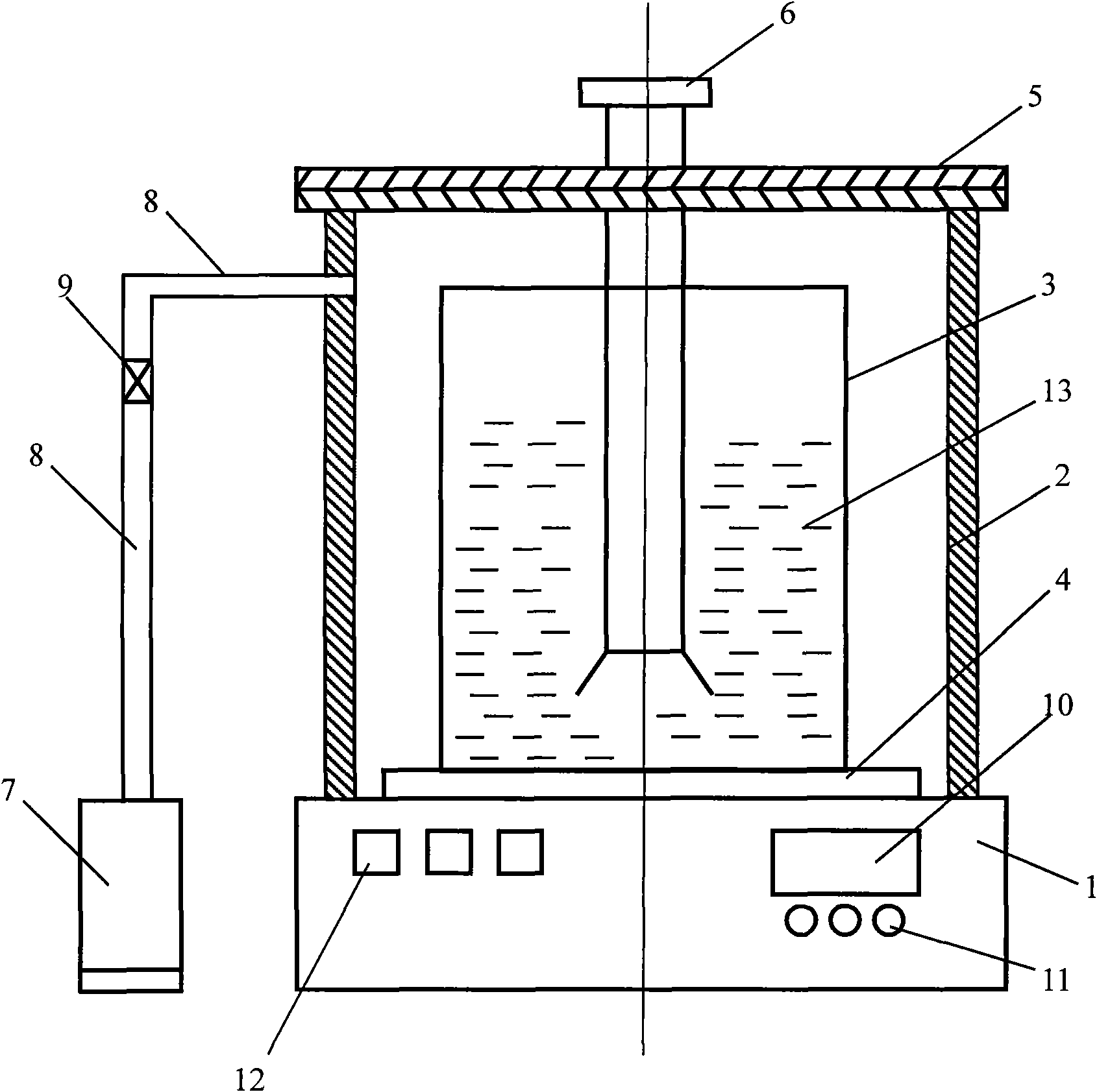

[0112] The present invention will be further described below in conjunction with accompanying drawing:

[0113] figure 1 As shown, it is the state diagram of the products of components A and B prepared in the reactor. The upper part of the reactor should be tightly sealed, and the vacuum pump should be vacuumed to keep the vacuum in the reactor at 0.09MPa. intervention.

[0114] Each value is accurate, strictly weighed, and the heating temperature is strictly controlled.

[0115] figure 2 Shown is the surface morphology of polyurethane elastomer after solidification. It can be seen from the figure that: for the addition of titanium dioxide TiO 2 The final scanning photo of the polyamic acid elastomer shows that the bright part is spherical nano-titanium dioxide particles with an average particle size of 20nm, which are uniformly dispersed in the matrix and are in close contact with the matrix.

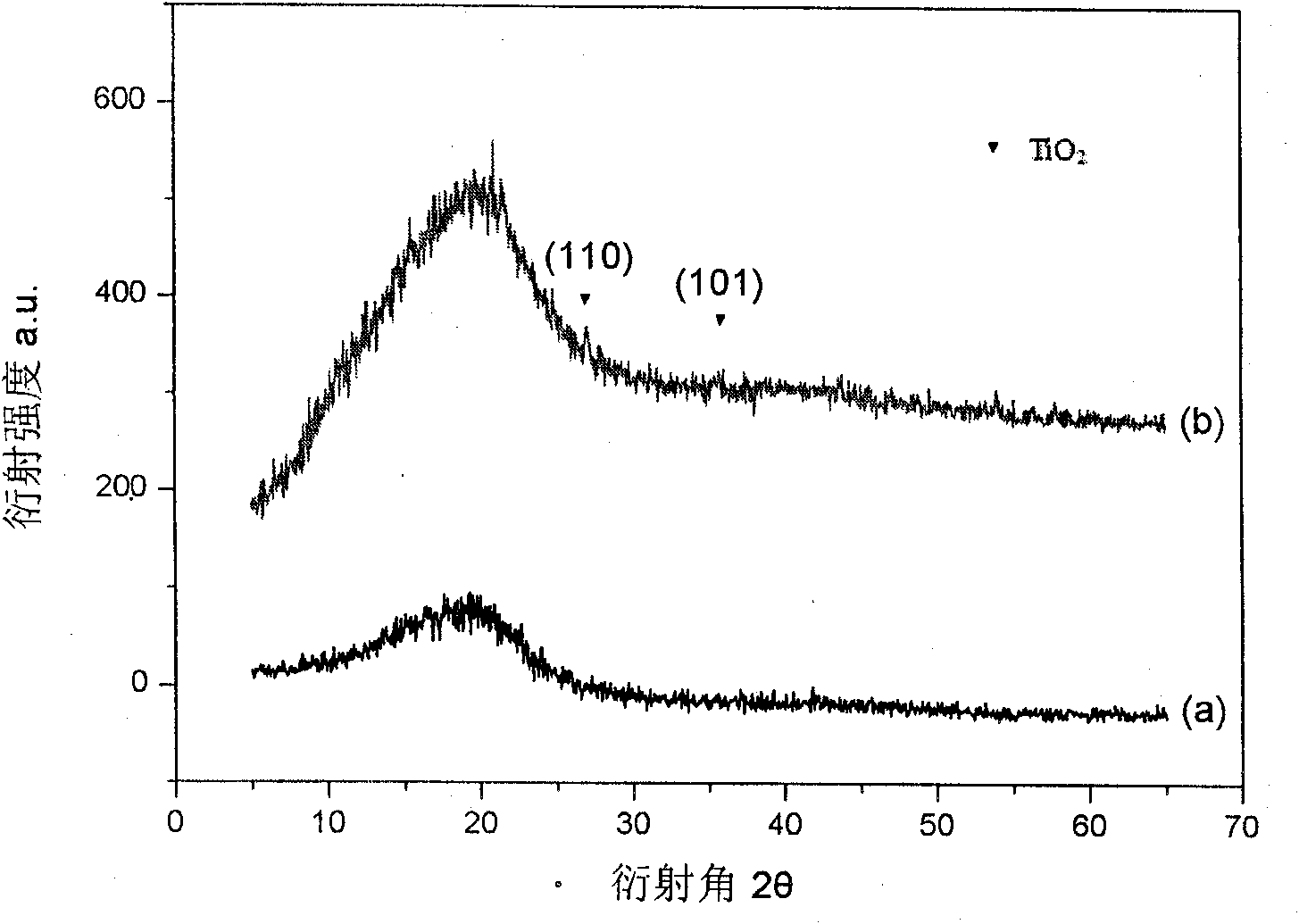

[0116] image 3 As shown, it is the diffraction intensity spectrum after sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com