Method for automatically adjusting arc length of slope characteristic type pulse consumable electrode gas shielded welding

A technology of pulse melting electrode and gas shielded welding, which is applied in welding equipment, arc welding equipment, manufacturing tools, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

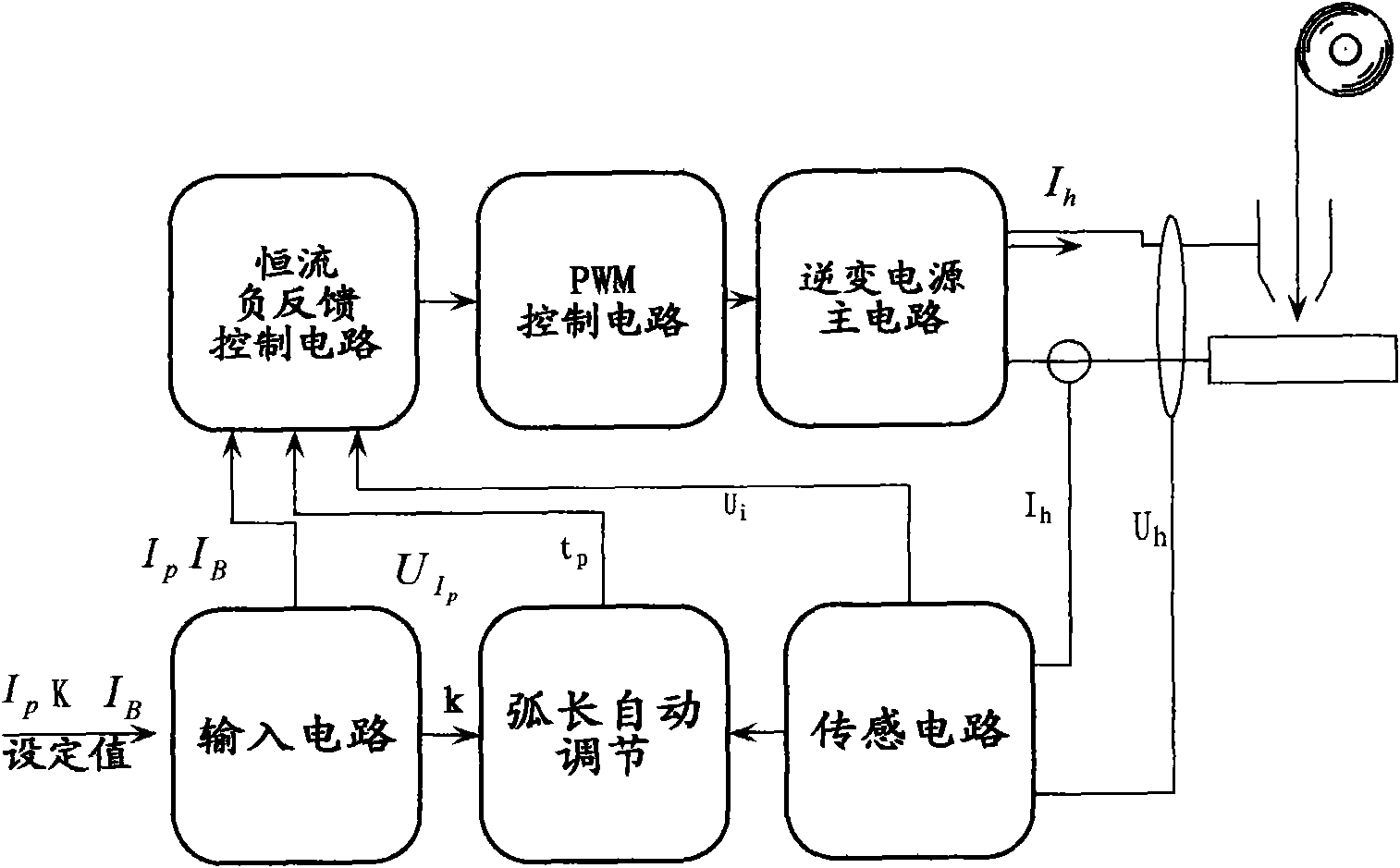

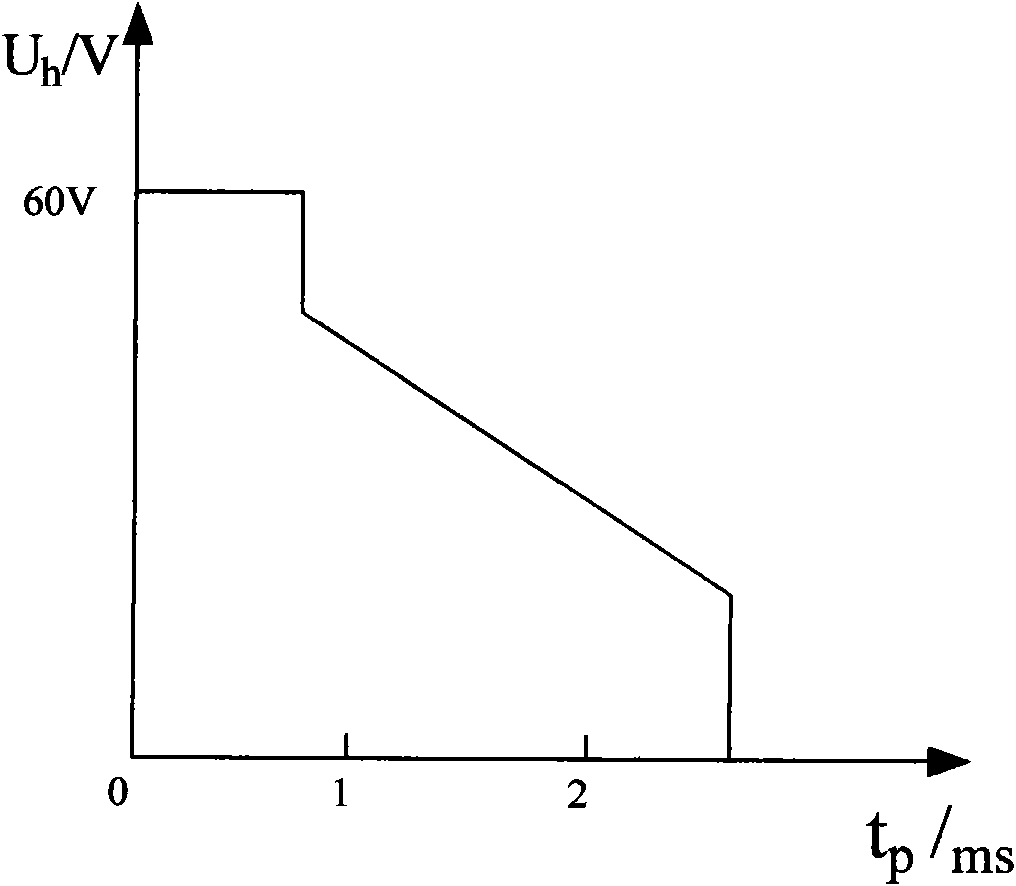

[0018] A method for automatically adjusting the arc length of the oblique characteristic pulse MIGA welding arc length, which mainly adopts the oblique characteristic pulse MIGA welding arc length automatic adjustment model to establish the oblique characteristic pulse MIGA welding power supply control system, adopts the pulse The slope design algorithm of the external characteristic of the metal gas shielded welding power source is used to quantitatively adjust the arc length and automatically adjust the intensity.

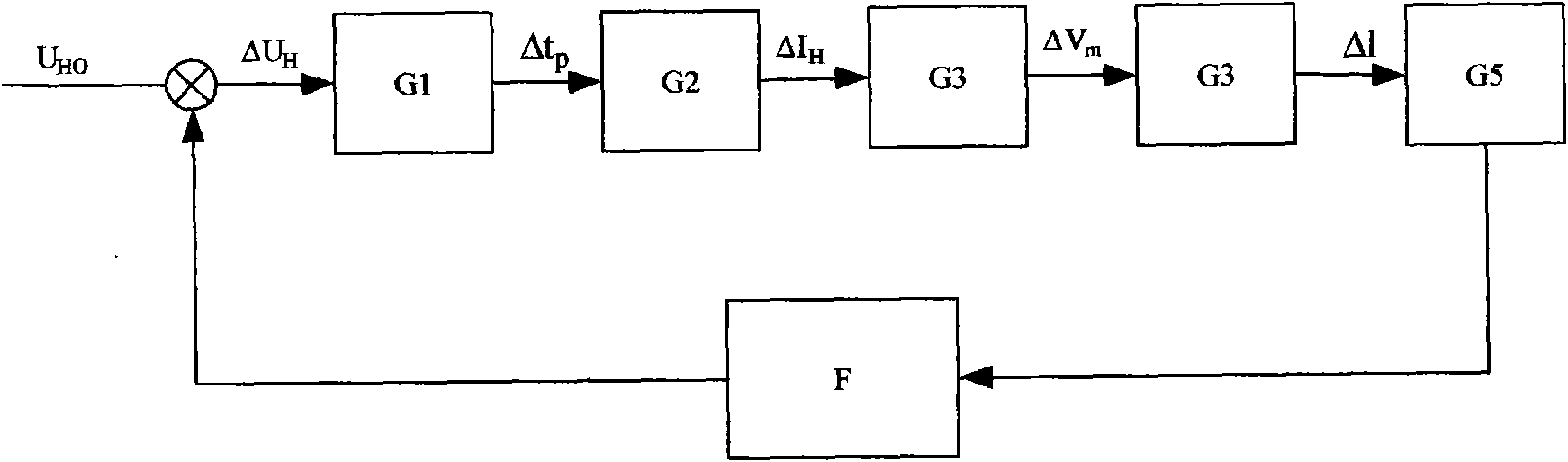

[0019] Depend on figure 1 It shows that the arc length automatic adjustment system of the present invention is based on pulse CO 2 Welding peak current time t p As the control volume, pulse CO 2 The slope characteristic relationship between the average current and voltage of welding is used as the criterion, and t is controlled by arc voltage closed-loop feedback p , so that the system can get a stable arc voltage operating point.

[0020] Depend on figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com