Method for preparing filter stick of cigarette

A cigarette filter rod and filter rod technology, which is applied to e-liquid filter, tobacco, tobacco processing and other directions, can solve the problems of complicated process, degraded cigarette smoking quality, poor filter rod filtering effect, etc., so as to optimize process parameters and simplify production process. , to improve the effect of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

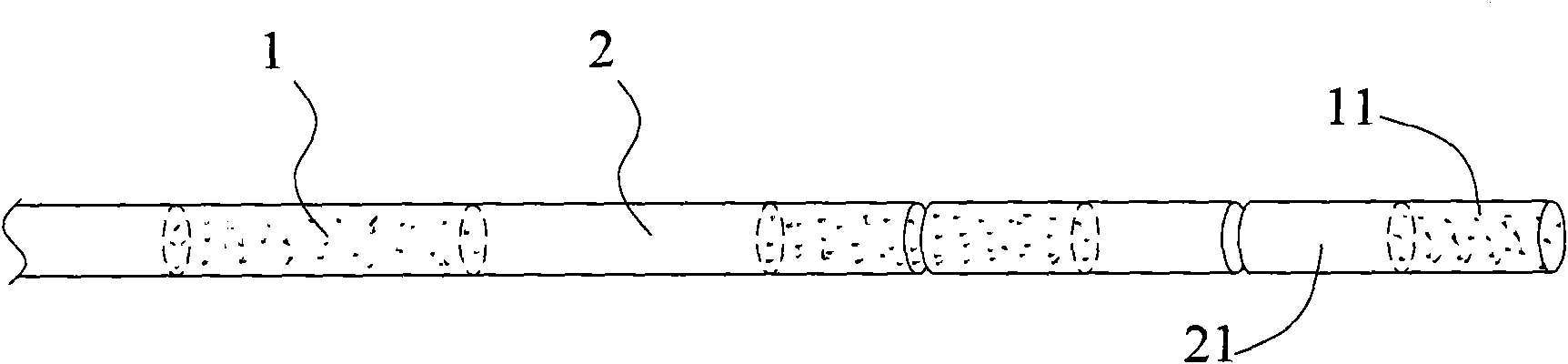

[0031] The present invention will be further described below in conjunction with the accompanying drawings.

[0032] The first is the production of tobacco stem particles. Tobacco stems are used as raw materials. The tobacco stems are not divided into origin, year and grade. The preparation of expanded tobacco stem particles for binary composite filter rods is carried out according to the following method:

[0033] 1 Tobacco stem expansion treatment Mix the raw stems with the microwave solid particle medium heated to 160-180°C evenly, place them in the microwave expansion equipment to make the tobacco stems expand rapidly, set the microwave action time to 90 seconds, and then separate and expand the tobacco stems and microwave solid particle medium;

[0034] 2. Moisturize the expanded tobacco stems to a moisture content of 30%, then store for 4 hours;

[0035] 3 Granulation The expanded tobacco stems after moisture resurgence enter the granulation equipment, and are granulate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com