Stretched laminated film and bag

A surface layer and barrier layer technology, applied in the field of stretch laminated film, can solve problems such as whitening, tightness of film content, insufficient heat shrinkage, etc., and achieve reliable packaging operations, good transparency, and excellent overlapping sealability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

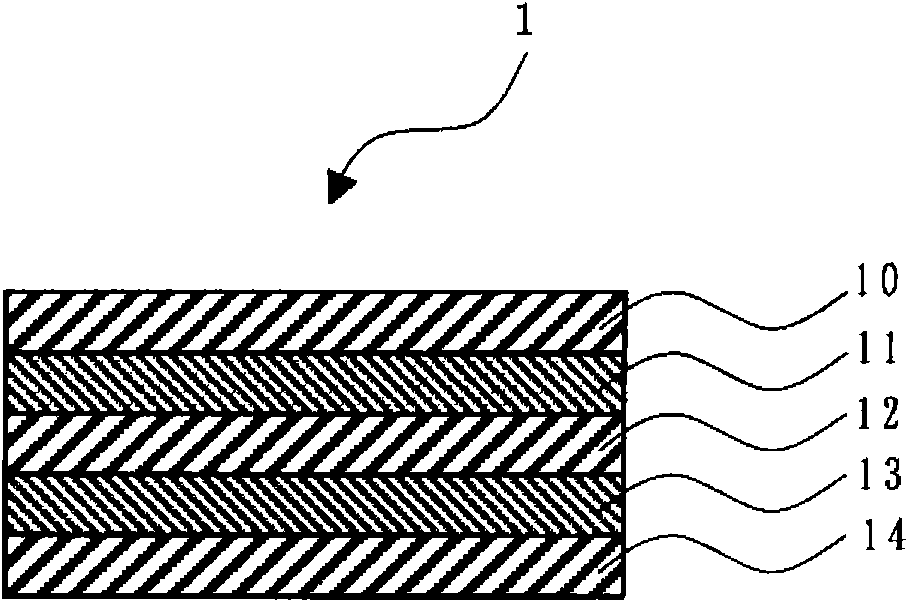

Image

Examples

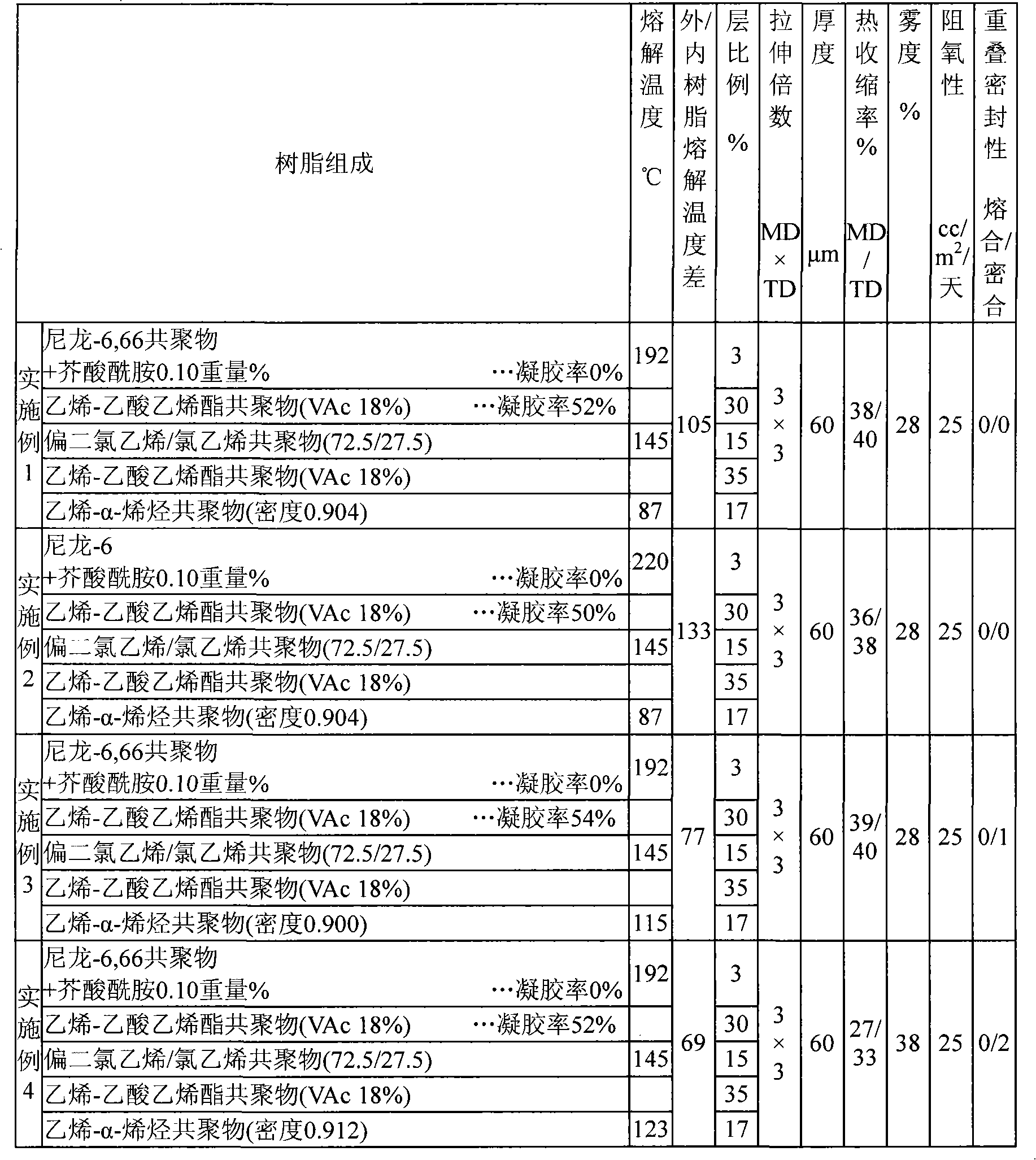

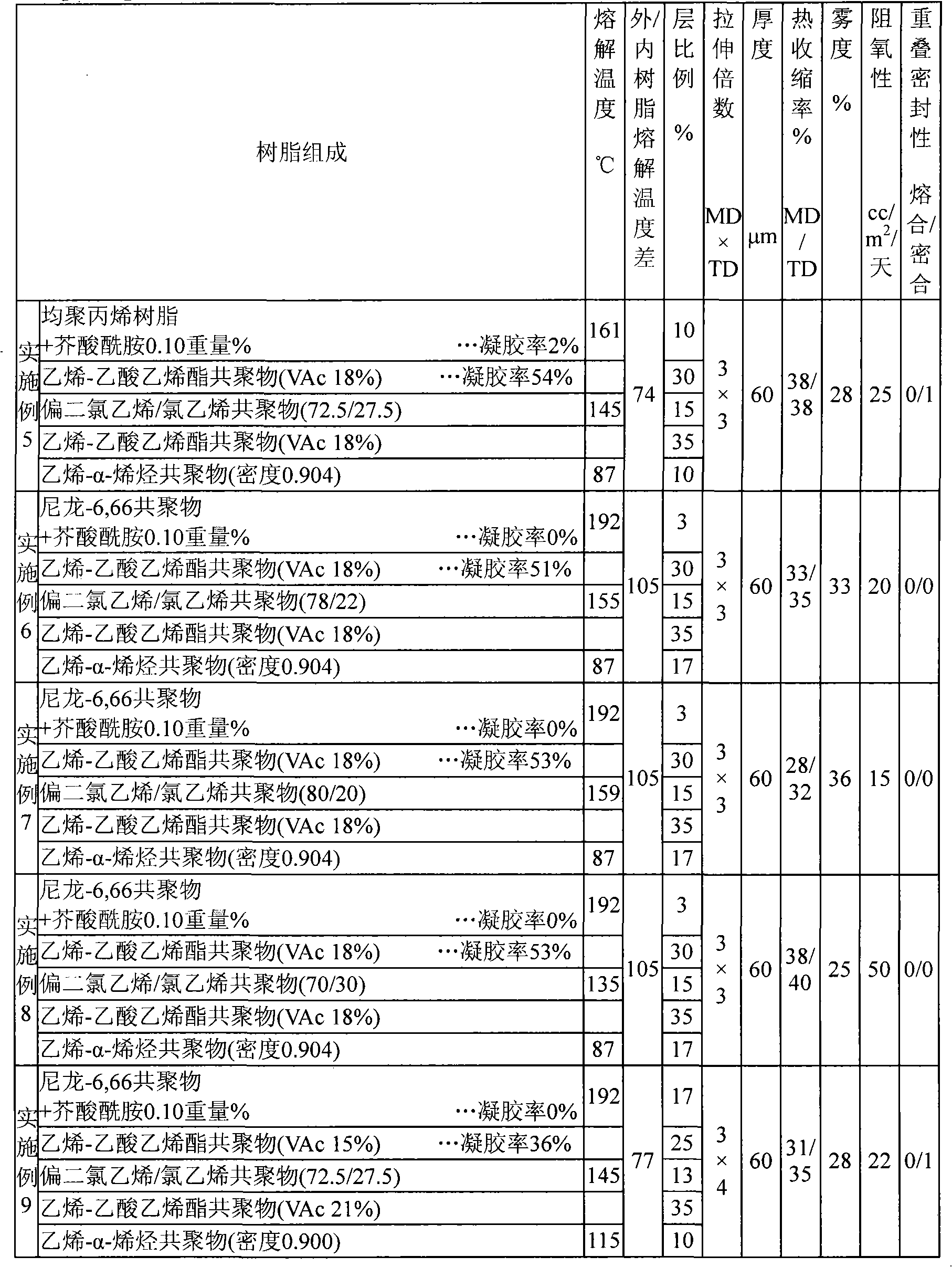

Embodiment 1~25、 comparative example 1~12

[0114] Examples 1 to 25 used the resins shown in Tables 1 to 6, Comparative Examples 1 to 12 used the resins shown in Tables 7 to 9, and used the necessary number of extruders corresponding to the number of layers, using the double film bubble inflation method Fabrication of stretch laminated films.

[0115] The ethylene-α-olefin copolymers used in Examples 3, 9, 23, 25 and Comparative Examples 1, 3, 5, 8, and 9 are ethylene-butene copolymers (density: 0.900 g / cm 3 , Melting point: 115°C, Melt index: 0.7g / 10min). The ethylene-α-olefin copolymers used in Examples 1, 2, 5-8, 10, 11, 13, 14, 16, 17, 20-22, 24, Comparative Examples 2, 6, 10-12 are ethylene- Hexene copolymer (density: 0.904g / cm 3 , Melting point: 87°C, Melt index: 2.5g / 10min). Embodiment 15, comparative example 3 use 38% by weight ethylene-hexene copolymer (density: 0.900g / cm 3 , melting point: 95°C, melt index: 4g / 10 minutes) and 60% by weight ethylene-hexene copolymer (density: 0.904g / cm 3 , melting point: 8...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com