Planar motor adopting three-dimensional permanent magnet array

A permanent magnet array, plane motor technology, applied in the direction of holding devices, magnetic circuits, electrical components, etc. using magnetic attraction or thrust, can solve the performance indicators such as affecting the movement stroke, response speed and movement accuracy, and the movement inertia of the plane positioning device is inconsistent. Balance and other issues to achieve the effect of improving acceleration and load capacity, and improving thrust and suspension capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific structure, mechanism and working process of the present invention will be further described below in conjunction with the accompanying drawings.

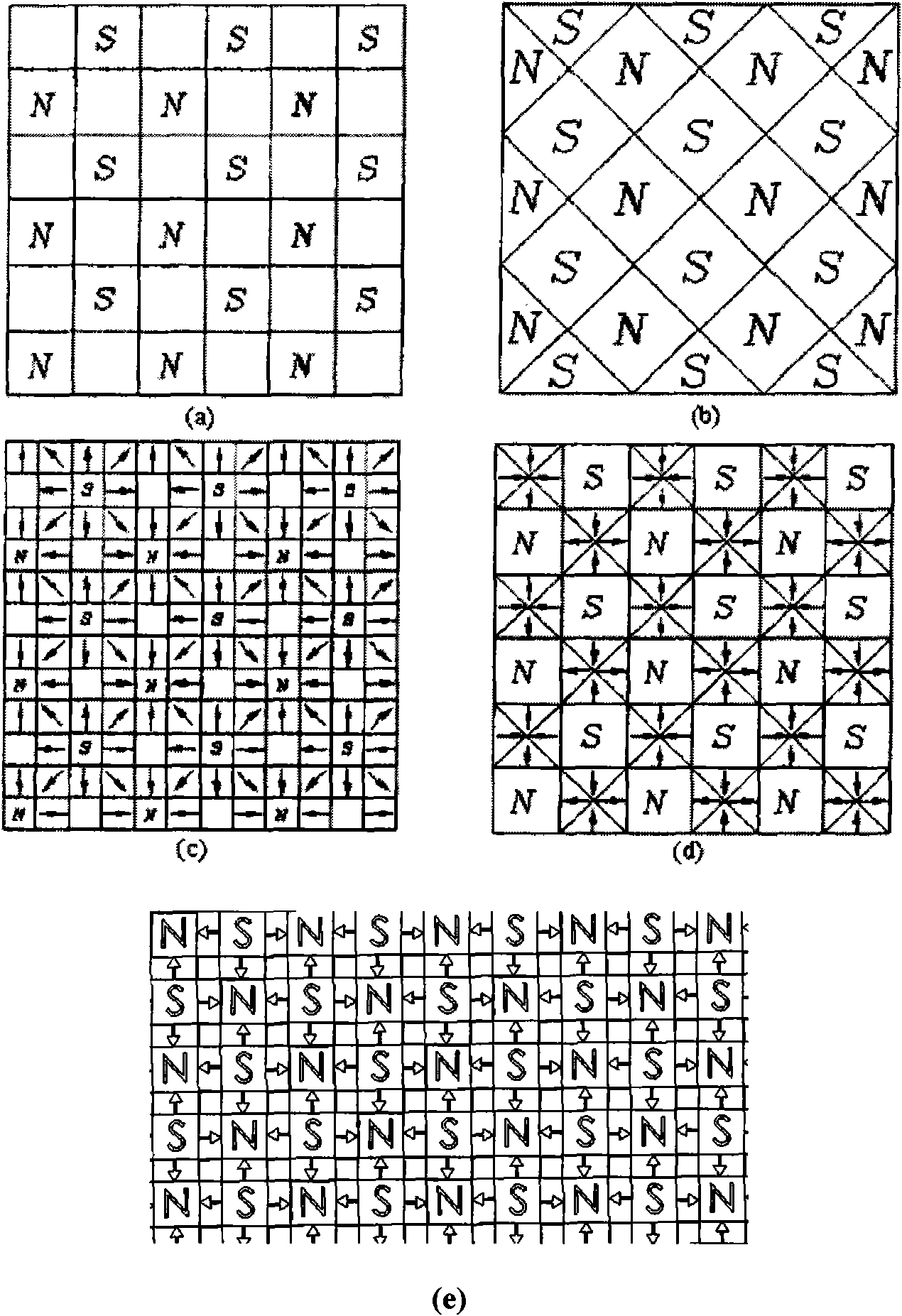

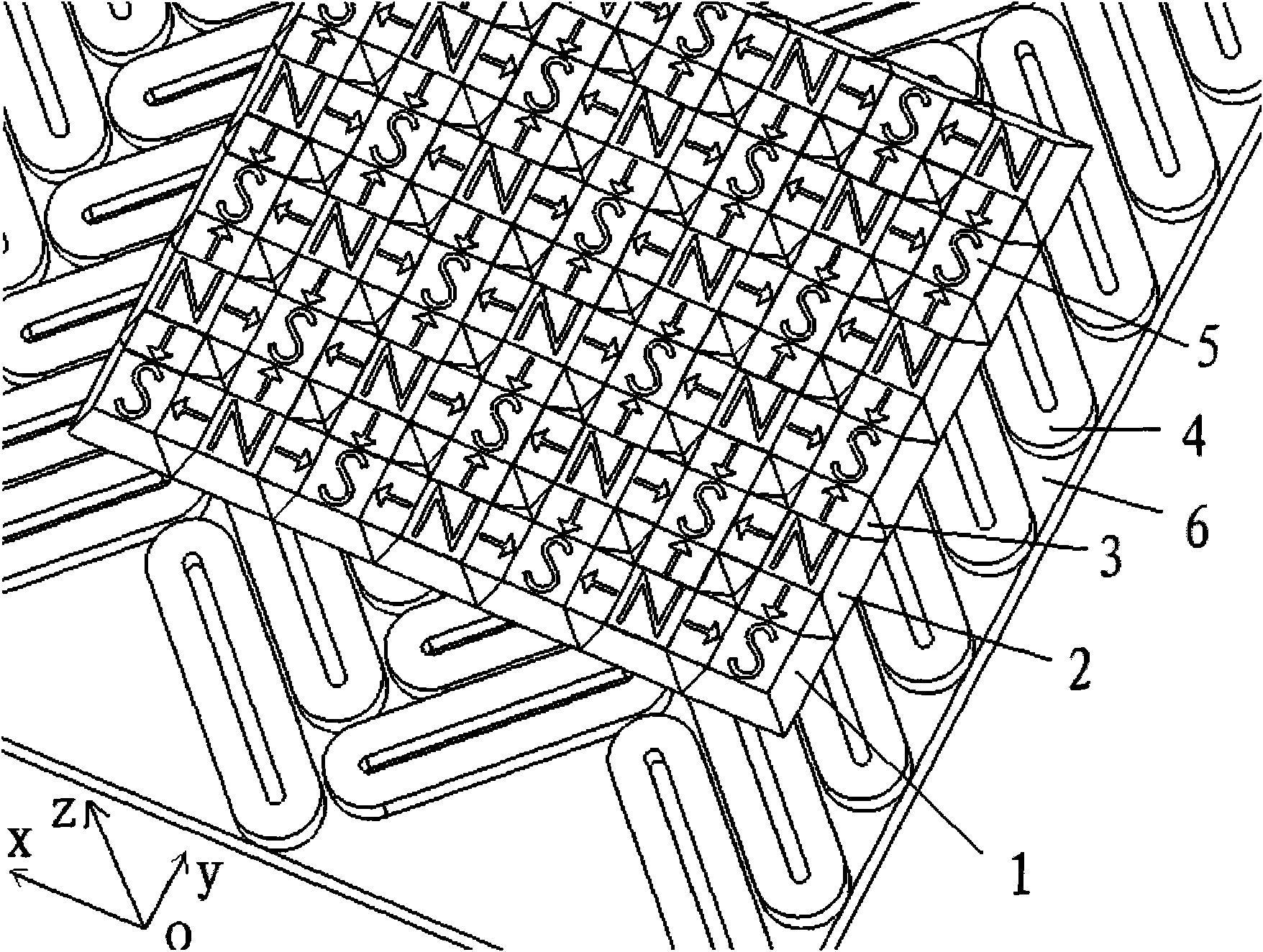

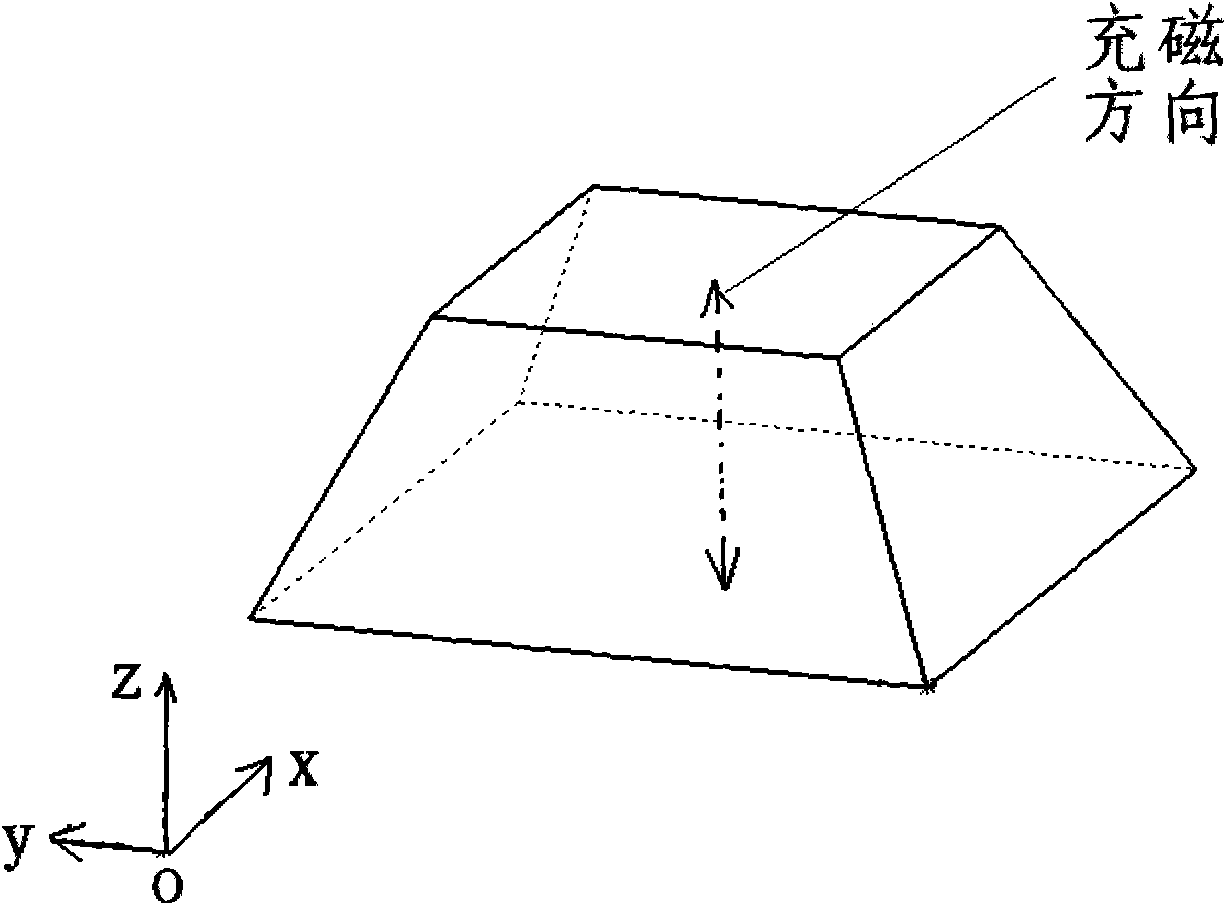

[0020] figure 2 It is a three-dimensional view of the planar motor using a three-dimensional permanent magnet array in the present invention. It can be seen from the figure that the planar motor using a three-dimensional permanent magnet array in the present invention includes a mover 5 and a stator 4, and the mover adopts a three-dimensional permanent magnet array. The permanent magnet array adopts a three-dimensional permanent magnet array. The three-dimensional permanent magnet array consists of an S-shaped regular square prism large permanent magnet 1 with an S pole on the upper bottom, an N-type regular square prism large permanent magnet 2 and a small permanent magnet 3 with an N pole on the upper bottom. The large permanent magnets of the S-type and N-type regular quadrangular prisms are magnetized along ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com