Method for testing electrochemical corrosion of welded pipe seam in high-stress state and sample of welded pipe seam

A measurement method and electrochemical technology, applied to electrochemical corrosion measurement under high stress state, the measurement method and the sample field used, can solve the problems of electrical conductivity, plastic deformation, slippage, etc., and achieve the effect of solving damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0047] The embodiment device comprises a universal (tensile) testing machine 19, an electrolytic cell 17, and the electrolytic cell 17 includes: a working electrode as the sample 10, an auxiliary electrode, a reference electrode, a salt bridge, and an electrochemical workstation.

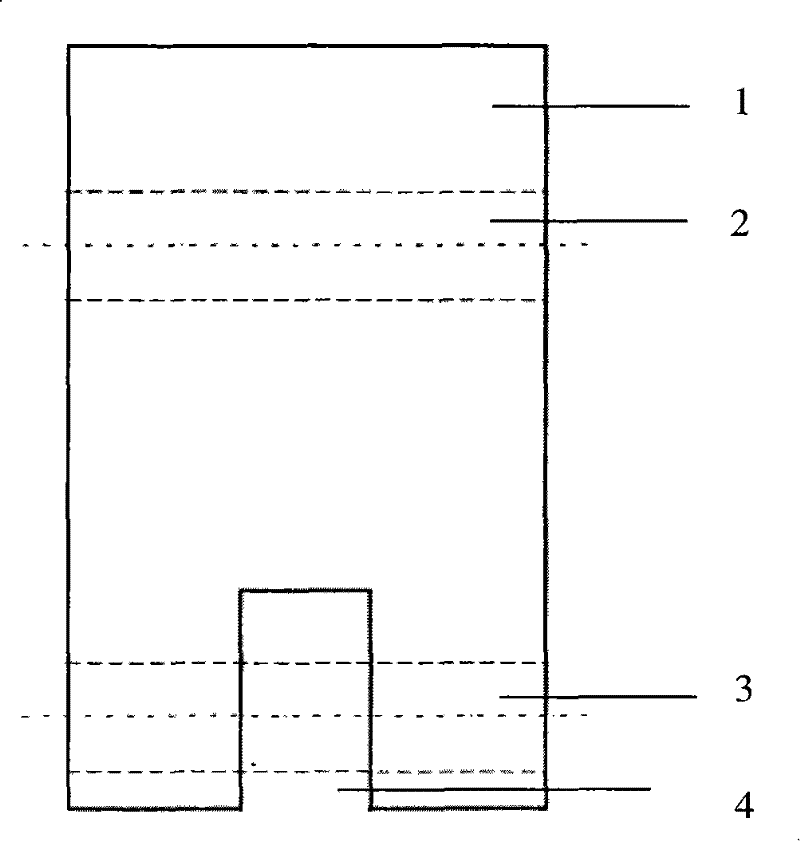

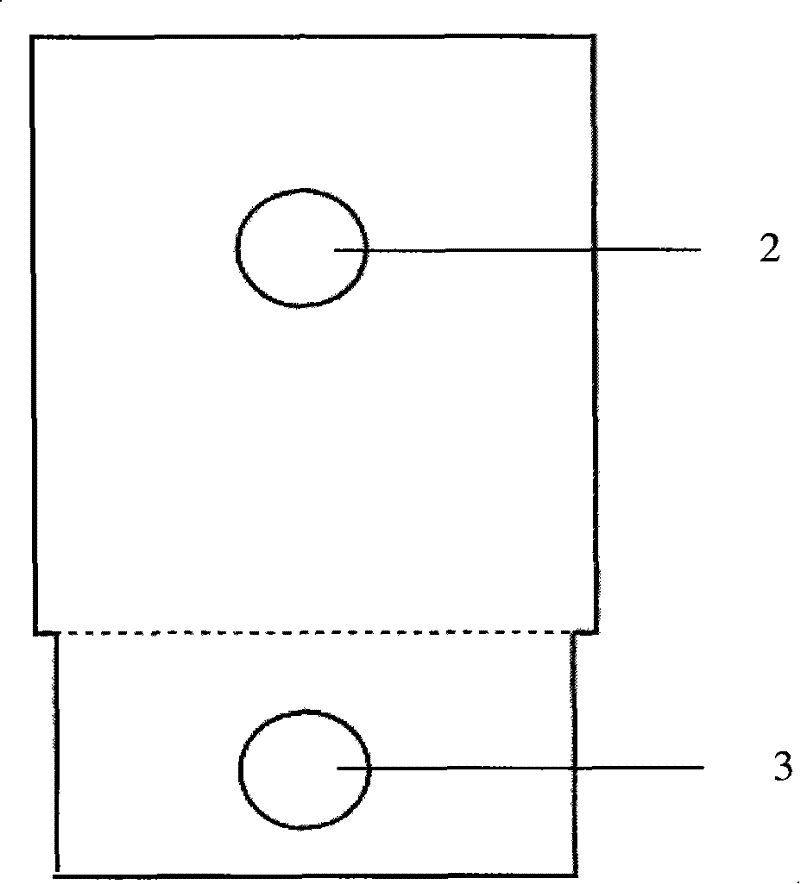

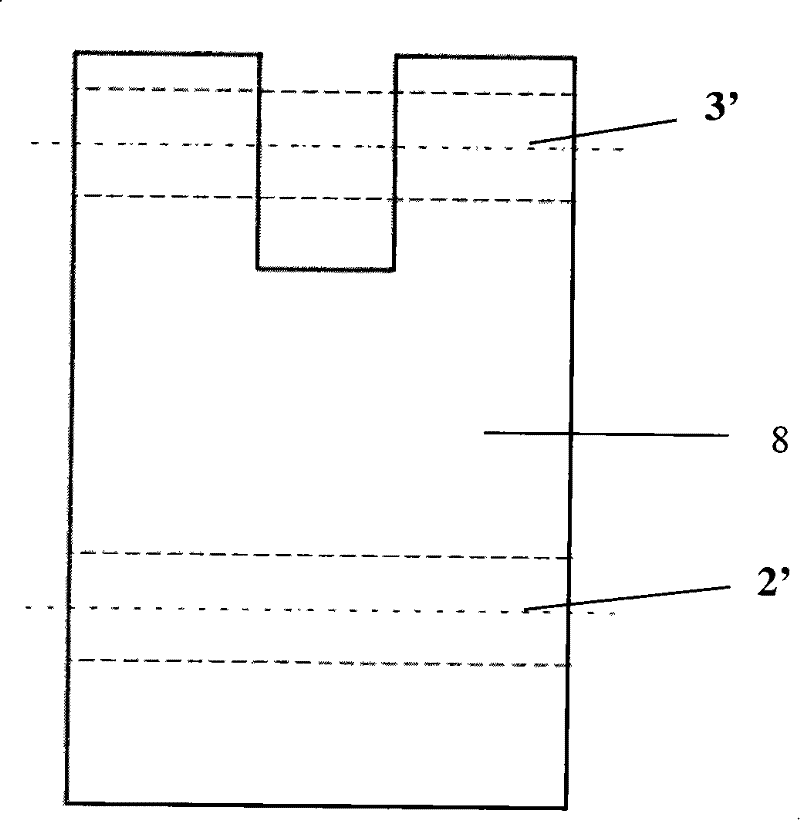

[0048] The upper and lower clamps of the electronic universal testing machine include the upper and lower joints 1,8 connected to the testing machine 19, the pins 11 for fixing the upper and lower joints, and the insulating pins 13,13' connecting the sample 10 and the joints 1,8. The joints of the upper and lower fixtures of the electronic universal testing machine have the same shape, and a through hole 3, 3' for bolt fixing is respectively opened on the upper and lower sides, and the two ends are respectively provided with sample connection grooves 4, 4'. The two pin holes 2, 2' connecting the fixture joints 1, 8 to the testing machine are inserted and fixed with uninsulated steel pins 11, and the ...

Embodiment 4

[0069] In addition to using the constant current method, the sample is 38mm wide at both ends, 13mm narrow in the middle, 11mm thick at both ends and 3mm thin in the middle, and the diameter of the connecting hole at both ends is 17mm, that is, the stress area of the hole at both ends of the sample and the middle weld The stress-bearing area ratio of the corrosion part is about 6:1, and the pressure of the insulating plug is guaranteed to be about 1 / 6 of the pressure of the corrosion area of the sample. No self-corrosion current has been measured, and the solution temperature is changed. Others are the same as in Examples 1-3. The measurements of the present invention were carried out.

Embodiment 5

[0071] Except that the sample is 42mm wide at both ends, 18mm narrow in the middle, 15mm thick at both ends and 6mm thin in the middle, and the diameter of the connection hole at both ends is 20mm, that is, the stress area of the holes at both ends of the sample and the stress area of the weld corrosion part in the middle The ratio is about 5:1, ensuring that the pressure of the insulating plug is about 1 / 5 of the pressure in the corrosion area of the sample, except that the temperature of the solution is changed, and the measurement of the present invention is carried out as in Examples 1-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com