Filament drawing device

A spinning device, monofilament technology, applied in filament/thread forming, complete equipment for producing artificial threads, non-woven fabrics, etc., to achieve uniform ventilation and sensitive adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

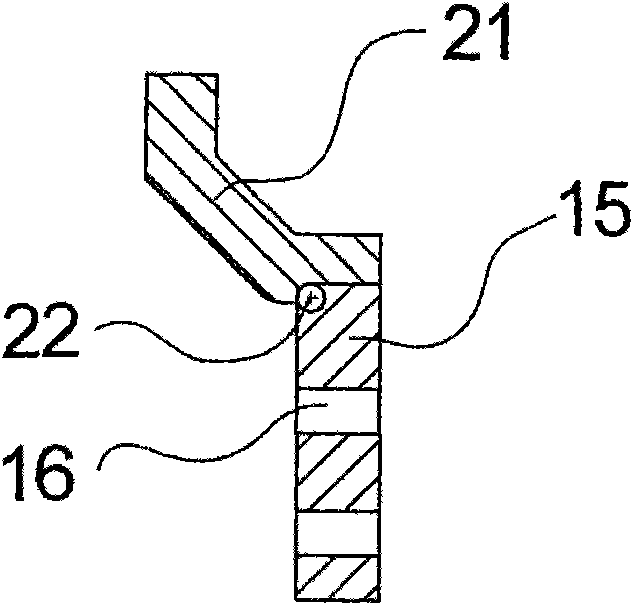

[0058] figure 1 An apparatus for melt spinning monofilaments and drawing the monofilaments into a nonwoven fabric according to the present invention is shown in . The molten polymer is fed from a melt source 1 , such as an extruder, via a melt conduit 2 to a spinning device 3 . The spinning unit 3 here contains a pump, not shown, for increasing the pressure and for metering the melt. Arranged on the underside of the spinning device 3 is a spinning nozzle 4 through which the melt is extruded into thin filaments which leave the spinning device 3 in the form of filament tufts 5 . The spinning nozzles 4 can be formed, for example, in a plurality of spinning nozzle plates arranged one after the other perpendicular to the plane of the drawing. Here perpendicular to the plane of the figure is set to have ratios in the plane of the figure and at figure 1 Several orders of magnitude more spinning nozzles 4 than those shown in . The monofilament cluster 5 thus has the shape of a cur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com