Alloy plastic wheelchair

An alloy plastic, wheelchair technology, applied in patient chairs or special transportation tools, vehicle rescue, medical transportation, etc., can solve problems such as troublesome parts assembly, achieve simple assembly, reduce production costs, and have beautiful and lightweight colors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

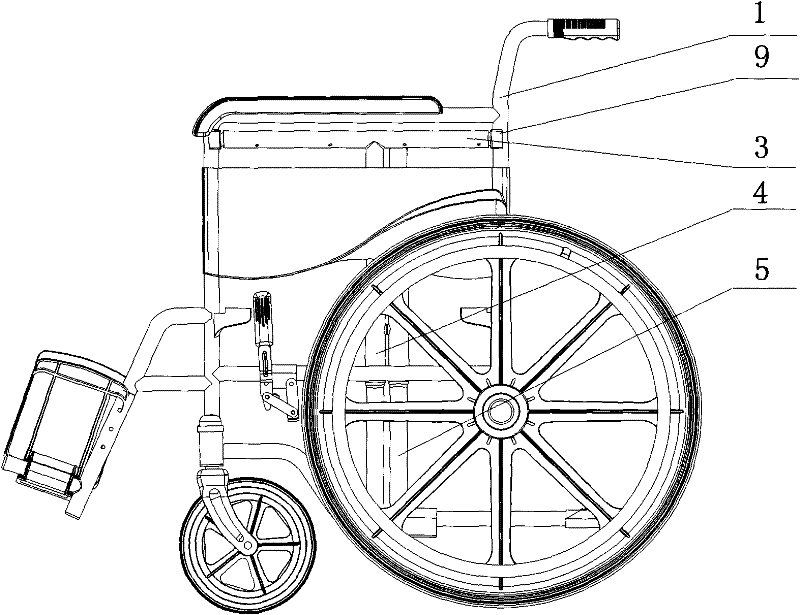

[0023] One end of slide block 9 is cylindrical, and the other end is square, and there is a large hemispherical cavity greater than hemisphere in the middle of the square.

[0024] The upper end of the cushion block 14 is an arc surface matched with the pipe rod, and the lower end edge has a recessed groove.

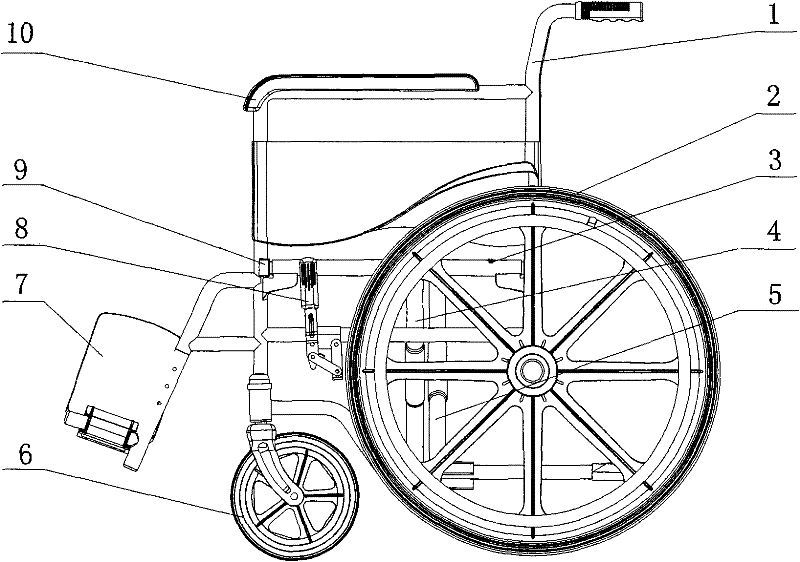

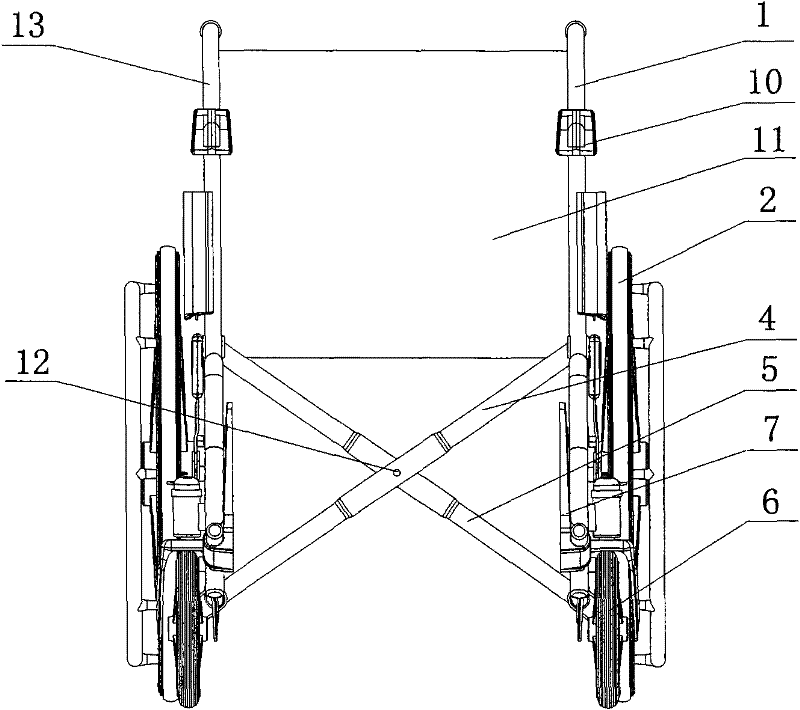

[0025] The left and right vehicle frames 1, 13 are disposablely molded into hollow tube frames with alloy plastics, and its cross-section is tubular but without pipe joints, and also can be disposablely molded into a cross-section as a rectangular frame.

[0026] The left and right vehicle frames 1 and 13 are symmetrical closed hollow tube frames, and the tops of the push rods 1-2 and 13-2 are handles 1-1 and 13-1, and the lower ends have shaft holes 1-6 protruding from both ends. 13-6, the outer surface place of front bar 1-11,13-11, push rod 1-2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com