Thin shoe cabinet without rear plate

A thin, back panel technology, applied in the field of shoe cabinets, can solve the problems of difficulty in dissipating foot sweat, unfavorable cleaning and protection of shoes, and bulky floor space, and achieves the effects of good ventilation, light weight and low material cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

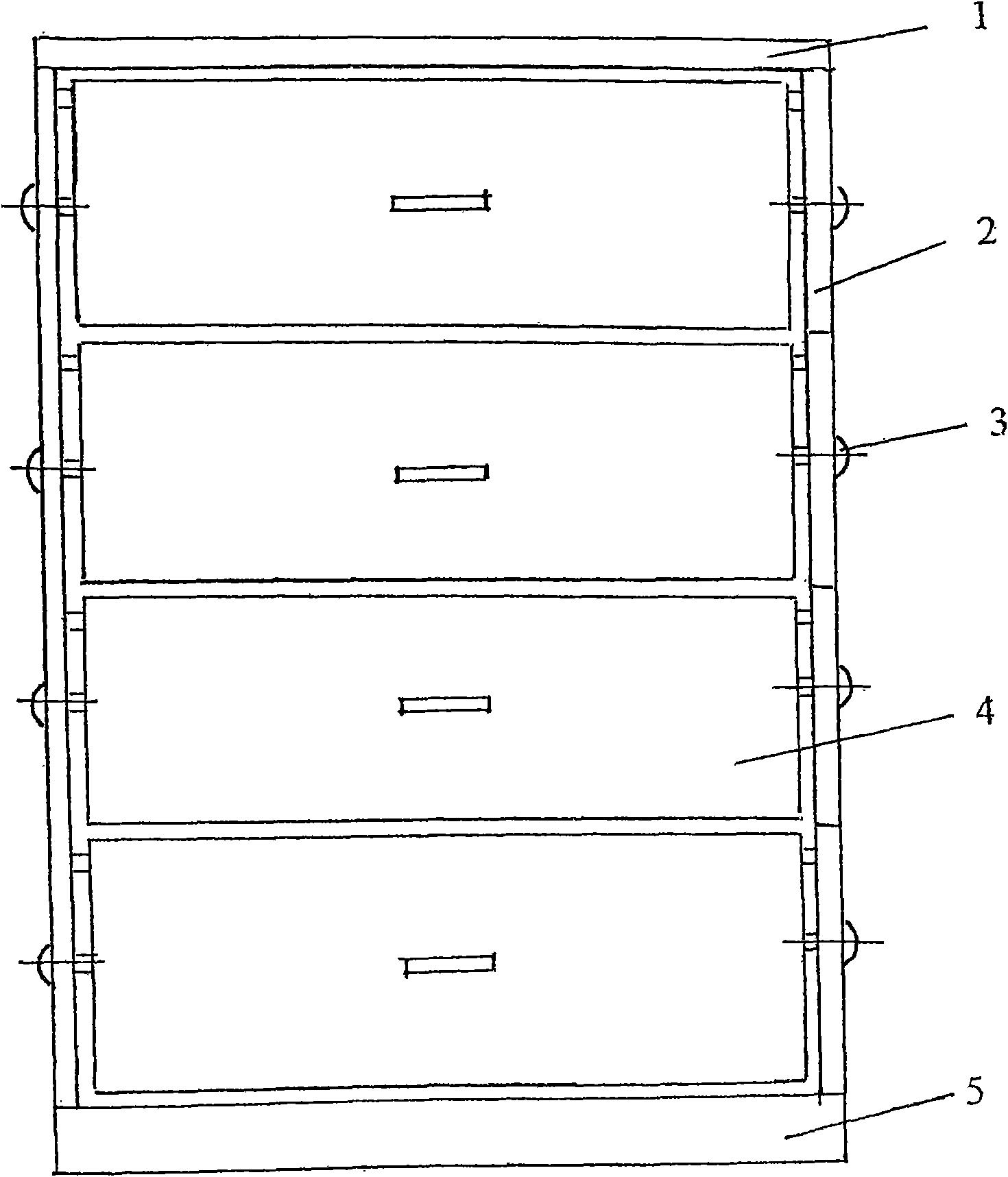

[0011] exist figure 1 In the shown embodiment, the shoe cabinet is a thin cube, and the base (5)

[0012] It is in the shape of a cuboid, the base (5) is about 10 cm wide, and the side plate (2) and the top plate (1) are combined to form a thin square frame by screws or bolts. There is no rear plate, and the multi-layer front panel assembly is embedded in the frame (4) Or set up a multi-layer bridge, pass the pin screw (3) through the small hole on the side plate (2) and the front panel assembly (4) and fix it with a nut, hold the handle on the front panel assembly, The front panel assembly (4) can turn over and swing at a certain angle around the pin screw (3), and the shoes are vertically placed in the front panel assembly (4). If multi-layer slats are set in the box body, the shoes are placed horizontally on the multi-layer slats, and the front door structure is designed. The front panel assembly (4) is composed of the front panel, the handle, and the shoe-blocking parts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com