Isolation buffer tri-level inversion circuit

A three-level inverter and loop technology, which is applied to electrical components, AC power input to DC power output, output power conversion devices, etc., can solve the problem of high design and manufacturing costs, high device requirements, and IGBT switch tubes. Low voltage stress and other problems, to achieve the effect of reducing the requirements for insulation strength, suppressing interference, and reducing the requirements for withstand voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings.

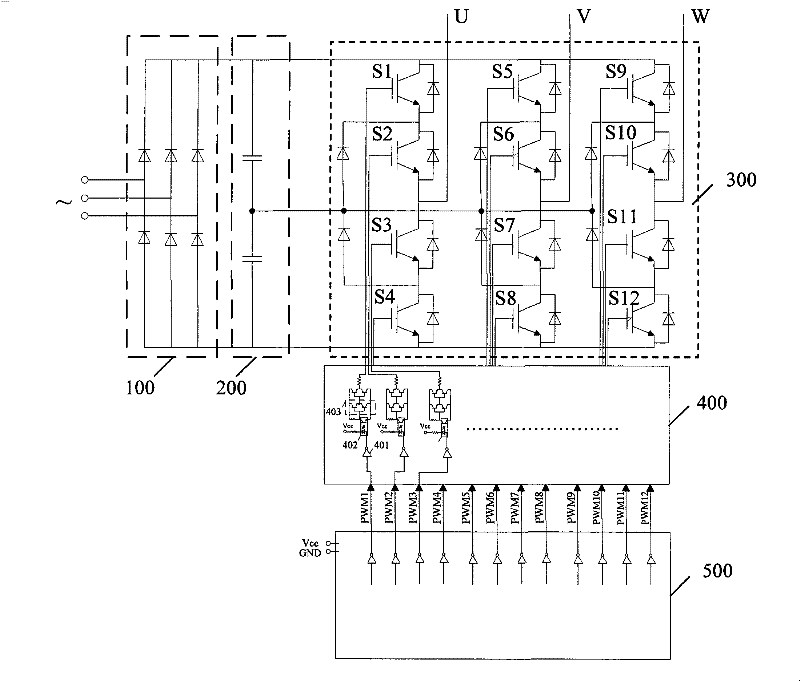

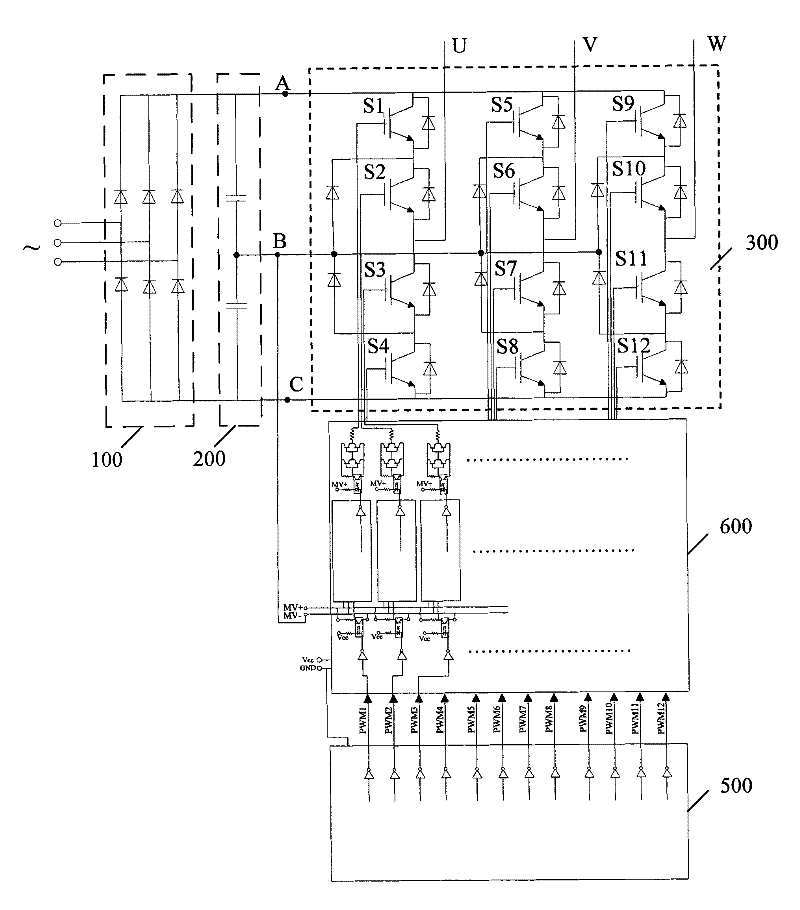

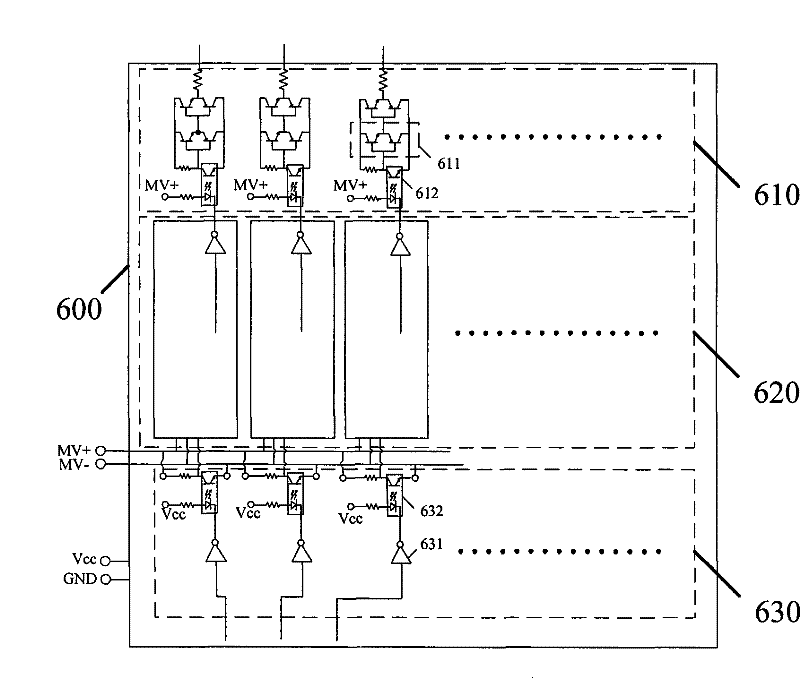

[0025] Such as Figure 2 to Figure 4 As shown, the isolated buffer type three-level inverter circuit of the present invention includes a rectification unit 100, a DC unit 200, an inverter unit 300, and a controller 500. The rectification unit 100 is connected to the DC unit 200, and the DC unit 200 is connected to the inverter unit 300. . An isolation buffer drive unit 600 is provided between the inverter unit 300 and the controller 500 , and the inverter unit 300 is connected to the controller 500 through the isolation buffer drive unit 600 (ie isolation coupling). The isolated buffer drive unit 600 includes a buffer unit 630, a conditioning unit 620, and a drive unit 610. The control signal output terminal of the controller 500 is connected to the IGBT switch tube of the inverter unit 300 via the buffer unit 630, the conditioning unit 620, and the drive un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com