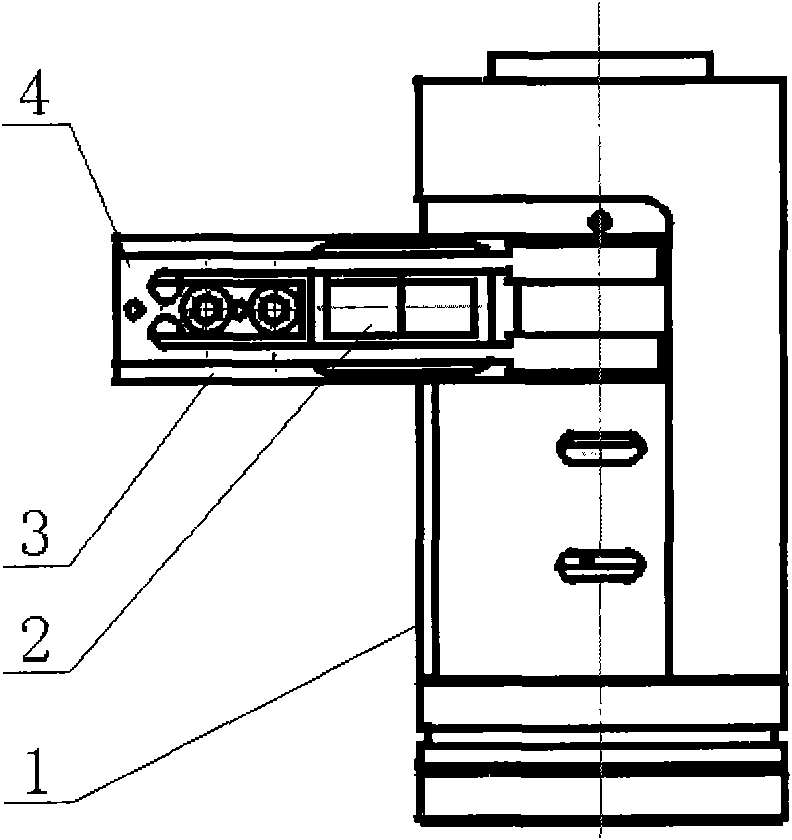

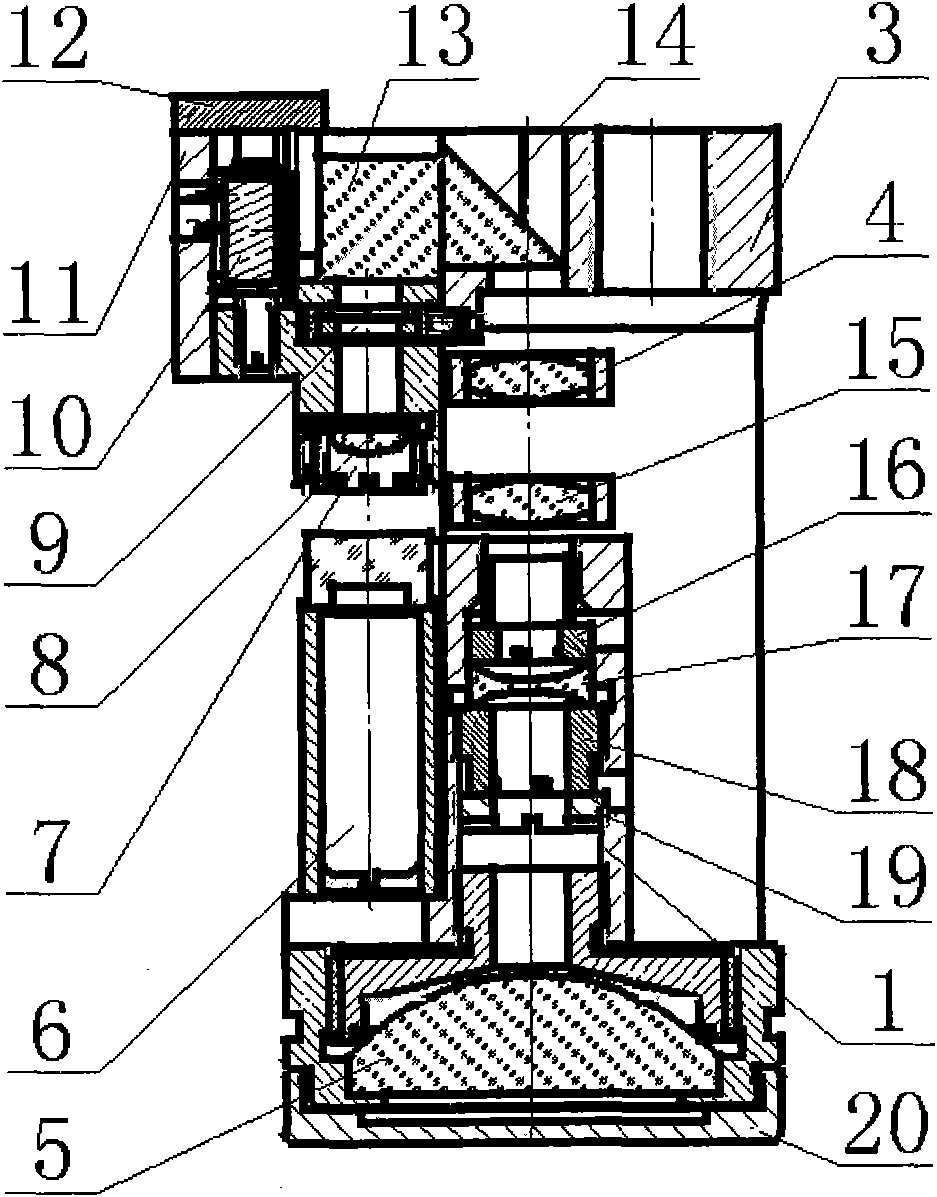

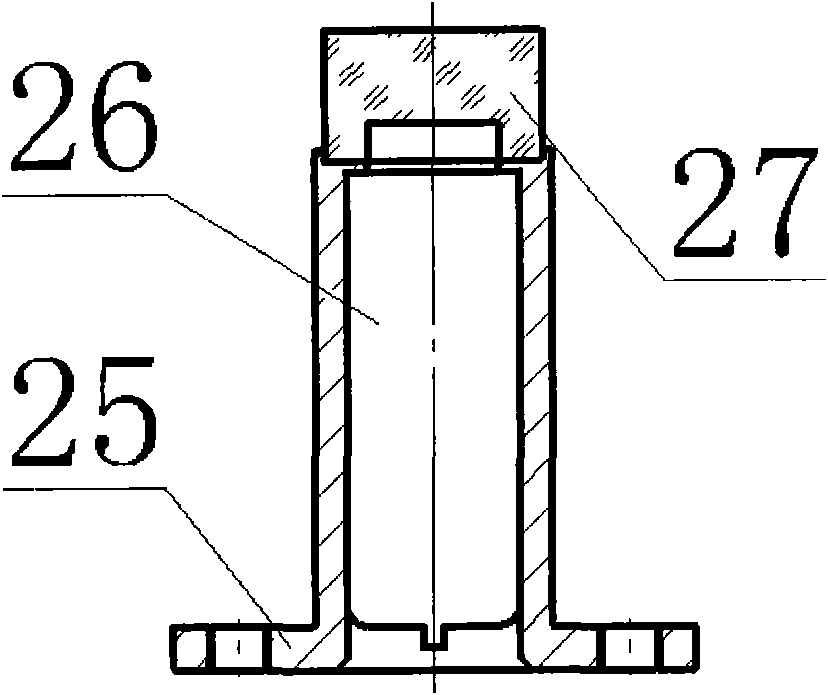

Confocal type laser test head based on time difference method

A technology of laser measuring head and time difference, which is applied in the direction of optics, measuring devices, optical components, etc., can solve the problems of unsuitable measurement, small range, large shape, etc., achieve the effect of compact and beautiful appearance, and make up for manufacturing errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0024] Use this probe to measure two gauge blocks with different standard values placed on the same plane, and the actual height difference between the two is 10 μm. Shoot the measuring beam of the measuring head on the above two gauge blocks respectively, and then record the measuring result of the measuring head, the result of the two measurements is the height difference obtained by the measuring head. The average value after multiple measurements is 10.7 μm, and the standard deviation is 0.5, which meets the measurement accuracy requirement of 3 μm required by the design.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com