Impeller of rotor for shaftless transmission pump

A technology of rotor impeller and shaftless transmission, which is applied in the direction of pumps, pump components, non-variable pumps, etc., which can solve problems such as difficult management, leakage, and high cost, and achieve the effect of less contact friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

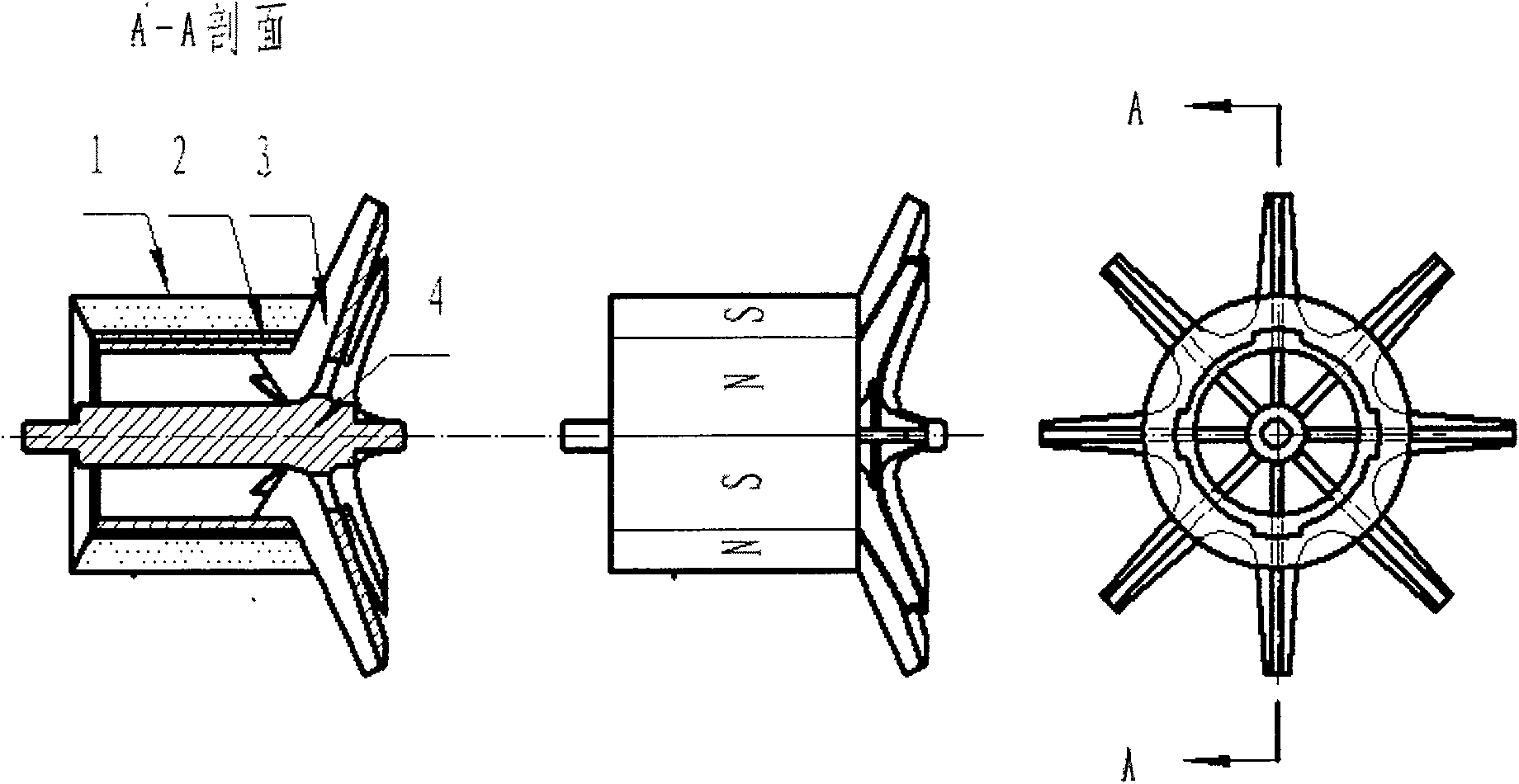

[0009] A shaftless drive pump rotor impeller according to the present invention is composed of a permanent magnet ring (1), a mouth ring (2), a blade (3), and a hub (4), and the mouth ring (2), blade ( 3), the hub (4) is molded integrally with a non-magnetic material, and the permanent magnet ring (1) is molded with ferrite and radially magnetized, and several pairs of N-S are formed on the outer cylindrical surface of the permanent magnet ring. The magnetic pole and the inner circle of the permanent magnet ring have grooves closely matched with the convex grooves on the outer circle of the mouth ring to form a rotor impeller for a shaftless transmission pump.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com