Method for extracting chlorogenic acid

A technology of chlorogenic acid and phase separation method, which is applied in the field of medicine and chemical industry, can solve the problems of small adsorption capacity and poor adsorption effect, and achieve the effect of easy operation and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

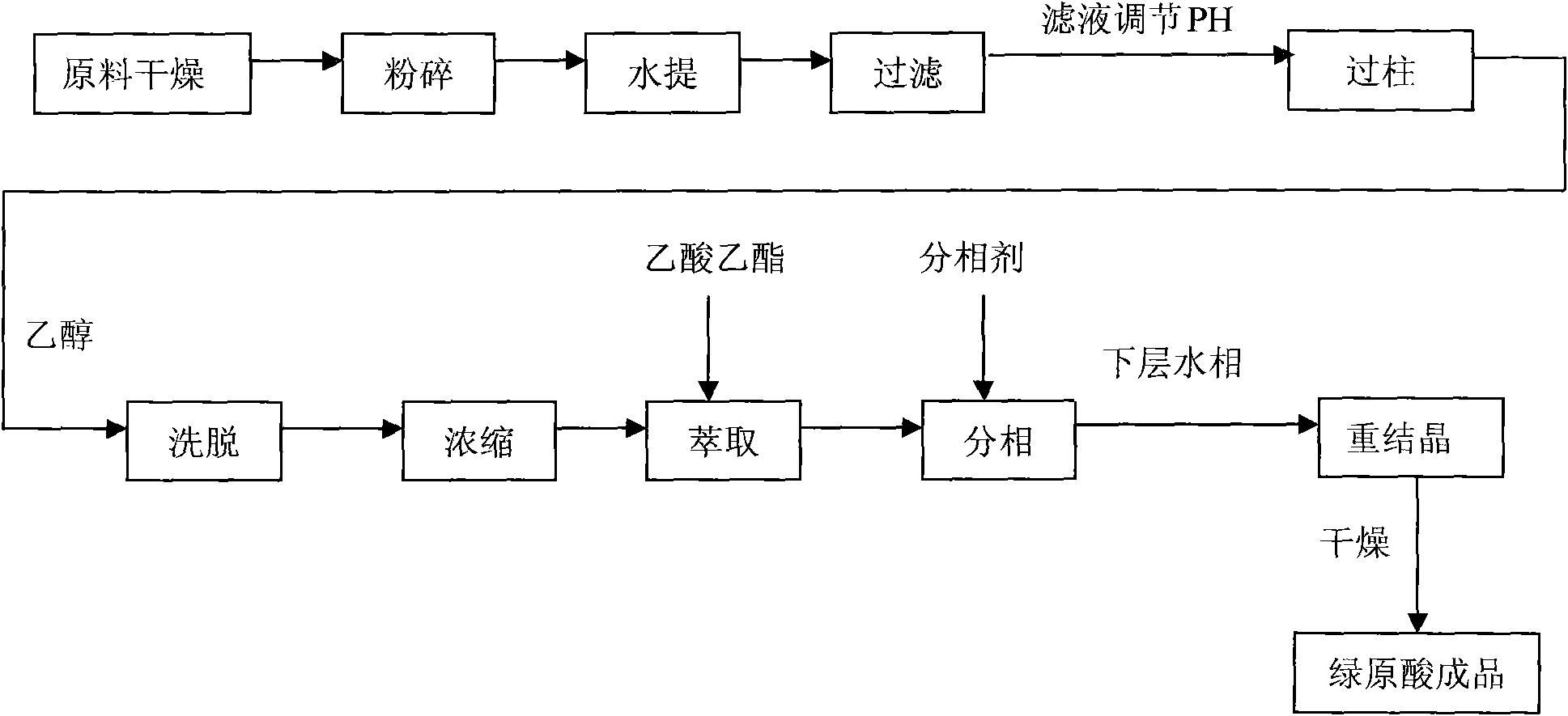

Image

Examples

Embodiment 1

[0022] a. Water extraction: Eucommia leaves are pretreated and dried at 45°C to 65°C for 5-6 hours. The samples were crushed to 40-60 mesh. Use water as the extraction solvent, solid-to-liquid ratio = 1:10, extract 3 times at 65°C, 45min / time, and filter.

[0023] b. Pass through the column: the filtrate obtained in step a is adjusted to pH2, put on a 306-type macroporous resin column, the flow rate is 2ml / min, eluted with 70% ethanol, and the eluent is concentrated;

[0024] c. Extraction: adjust the pH of the concentrated solution obtained in step b to 2, add ethyl acetate for extraction.

[0025] d. Phase separation: add petroleum ether to the extract obtained in step c, which is 40% of the volume of the extract, fully mix, and collect the lower aqueous phase;

[0026] e. Recrystallization: the aqueous phase obtained in step d is crystallized, recrystallized, and vacuum-dried to obtain the finished product of chlorogenic acid.

[0027] The purity of the sample can reach ...

Embodiment 2

[0029] a. Water extraction: honeysuckle pretreatment, at 45°C to 65°C, dry for 5-6 hours; crush the sample to 40-60 mesh; use water as extraction solvent, solid-liquid ratio = 1:10, 65°C, 45min / time, Extract 3 times and filter.

[0030] b. Pass through the column: the filtrate obtained in step a is adjusted to pH 1, put on the XAD-6 type macroporous resin column, the flow rate is 2ml / min, elute with 70% ethanol, and the eluent is concentrated;

[0031] c. Extraction: adjust the pH of the concentrated solution obtained in step b to 1, add ethyl acetate for extraction.

[0032] d. Phase separation: add chloroform to the extract obtained in step c, which is 40% of the volume of the extract, fully mix, and collect the lower aqueous phase;

[0033] e. Recrystallization: the aqueous phase obtained in step d is crystallized, recrystallized, and vacuum-dried to obtain the finished product of chlorogenic acid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com