Method for preparing bleaching powder and anhydrous calcium chloride by utilizing carbide slags to treat chlorine water

A technology of anhydrous calcium chloride and carbide slag, applied in the direction of calcium/strontium/barium chloride, hypochlorous acid, hypochlorite, etc., can solve problems such as incomplete treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

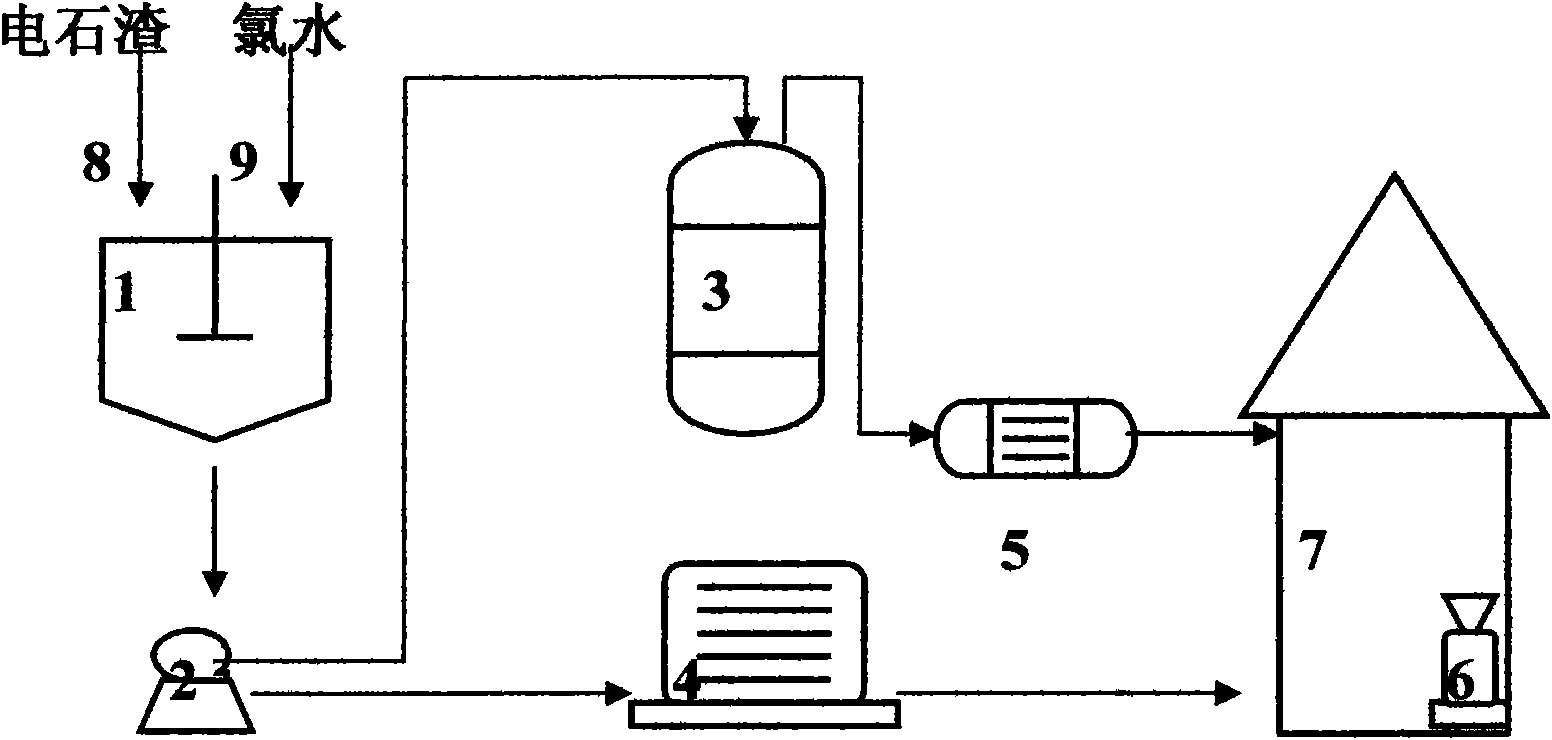

Image

Examples

Embodiment 1

[0015] Embodiment one: (dull chlorine water contains hypochlorous acid 1.2%; Contains chlorine gas 0.3%)

[0016] 500 kilograms of calcium carbide slag (8) and dull chlorine water (9) with a content of 75% are mixed in the processor (1) according to a mass ratio of 1:10, and the reaction is carried out with slow stirring for a long time of 2-3 hours until the reaction The liquid test is free of chlorine and hypochlorite. If there is, continue to add slaked lime until the reaction is complete.

[0017] Now above-mentioned reaction solution is carried out suction filtration, and the filter cake that suction filtration (2) obtains is calcium hypochlorite, obtains the calcium hypochlorite finished product of 91.95 kilograms through drying (4) pulverization (6), and filtrate is dihydrate chlorine Calcium chloride obtains 26.39 kilograms of anhydrous calcium chloride finished products through decompression deep distillation (3) through condensation (5), and then enters the finished...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com