Steel rail flash welding machine

A flash welding machine and rail technology, applied in welding equipment, resistance welding equipment, metal processing equipment, etc., can solve the problems of complex structure, large size and weight, and difficult manufacturing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

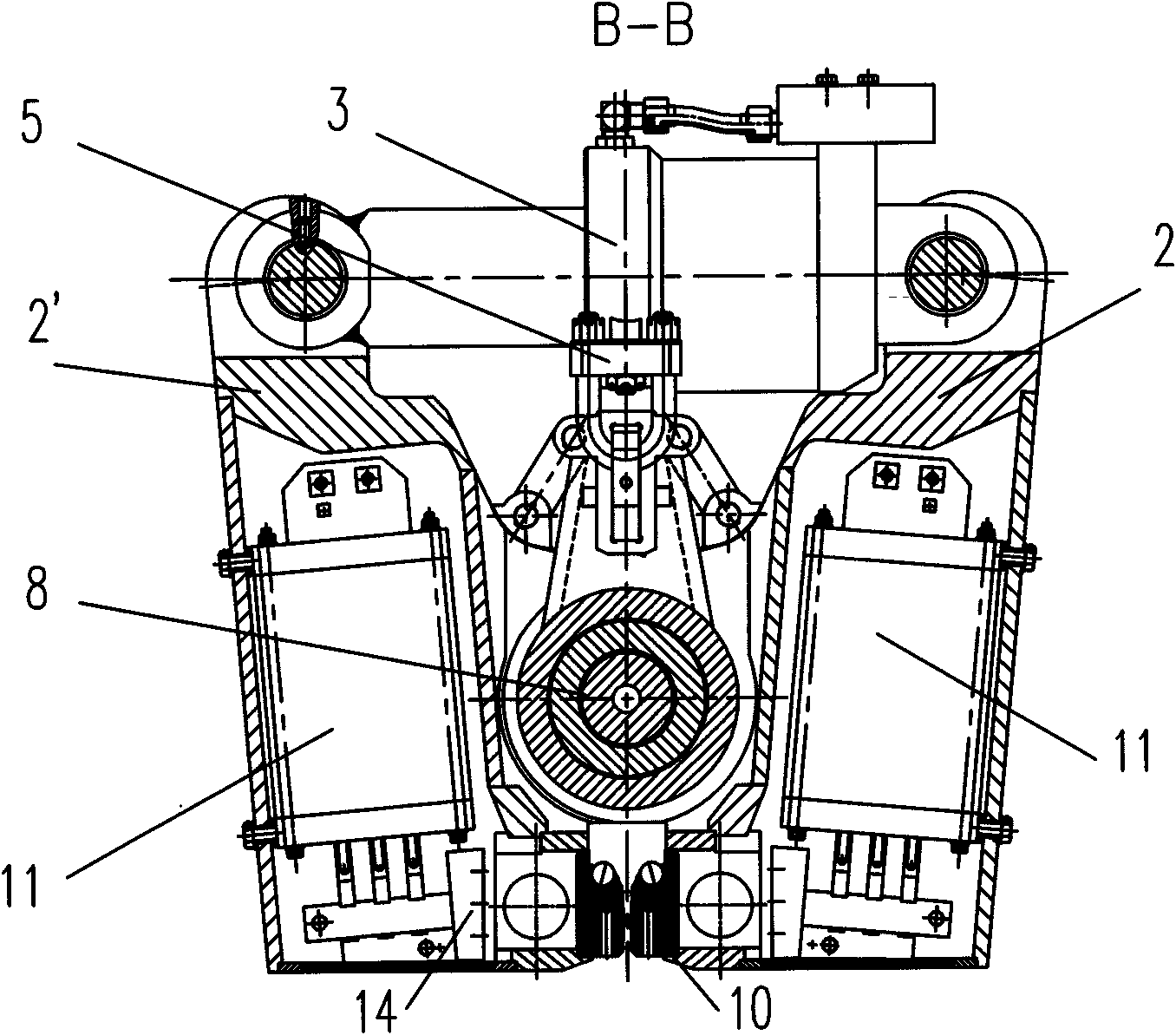

[0043] Such as figure 1 , 2 , 3, 4, 5, 6, 7, 8, and 9, the rail flash welding machine of the present invention includes a first pair of boxes 2, 2', a second pair of boxes 6, 6', a central axis 8, Clamping cylinder 3, upsetting cylinder 7, tumor pushing device 1 and welding transformer 11, wherein the first pair of boxes 2, 2' and the second pair of boxes 6, 6' are mounted on a common central axis 8 through hinges Two pairs of pincer clamping devices, each pair of pincer clamping devices is equipped with a clamping cylinder 3 between the boxes to drive the first pair of boxes 2, 2' and the second pair of boxes 6, 6' around the center The shaft 8 rotates axially, and an upsetting oil cylinder 7 is installed between the first pair of boxes 2, 2' and the second pair of boxes 6, 6' to realize the relative movement of the two pairs of boxes along the axis of the central axis 8, and the two welding The transformer 11 is installed in the first pair of boxes 2, 2' or the second pair...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com