Soluble fodder enzyme and production process thereof

A manufacturing method and soluble technology, applied in applications, animal feed, animal feed, etc., can solve the problems of enzyme activity inactivation, etc., achieve the effect of small enzyme activity loss, reduce the loss of enzyme activity, and avoid the loss of enzyme activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Weigh 4.5kg of ZnSo4 7H2o, 1.5kg of anhydrous CaCl2, 40kg of sorbitol, 40kg of lactose, 20kg of β-cyclodextrin and 3kg of sodium carboxymethylcellulose, and slowly add it to 440Kg of phytic acid with an enzyme activity of 20676u / g In the enzyme concentrated solution, heat while stirring, and control the temperature to be less than 40°C. After all the solids are dissolved, the liquid is spray-dried to obtain 115Kg of phytase soluble powder with an enzyme activity of 55000u / g. This product is easily soluble at 5-10°C while stirring, and the solution is clear and transparent after dissolution.

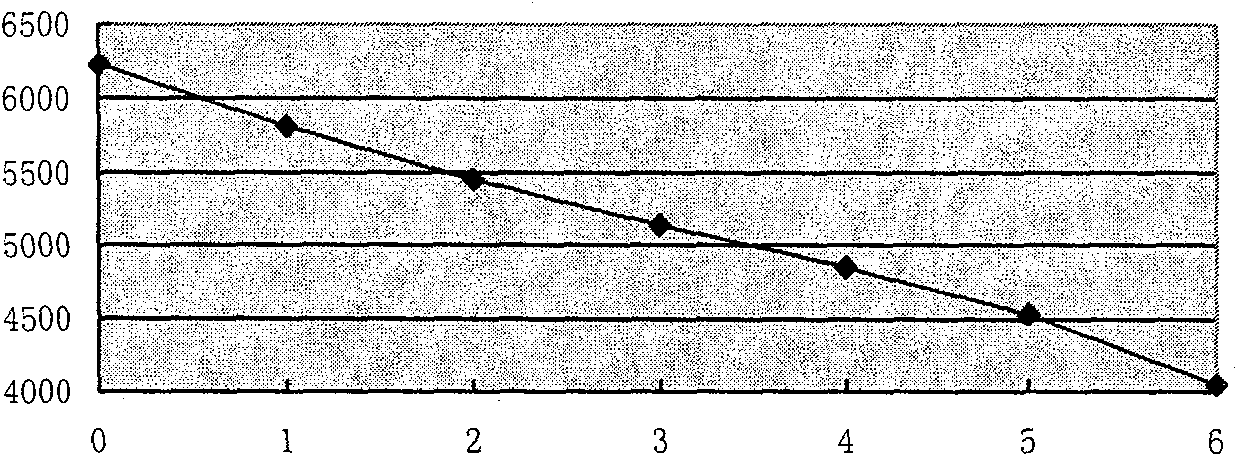

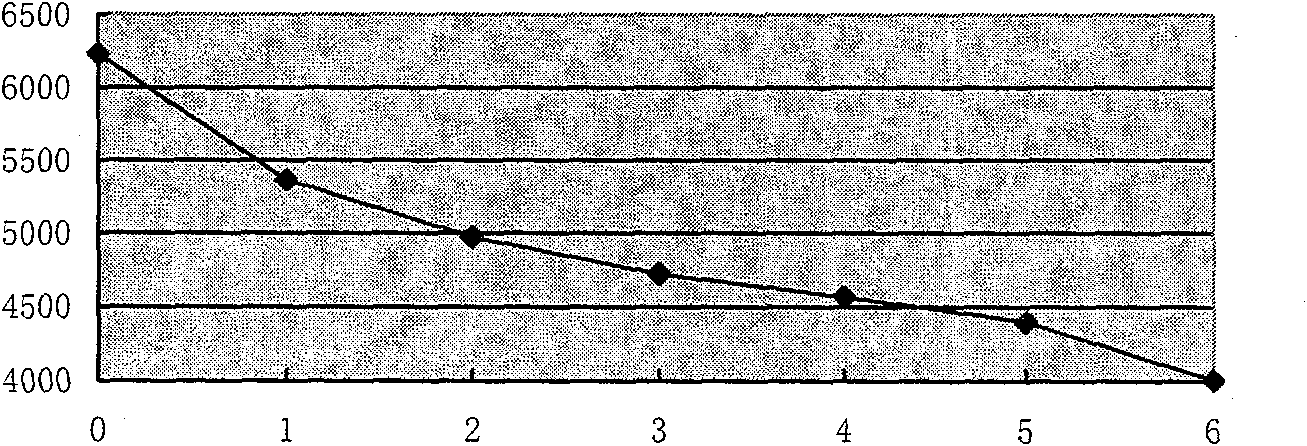

[0040] Figure 13 Shown is the stability analysis of the phytase in this product stored at room temperature for 6 months. According to the analysis and calculation, the enzyme activity retention rate of the phytase in this product stored at room temperature for 6 months is 98%. Figure 14 Shown is the stability analysis of the phytase in this product stored at a constant temperatu...

Embodiment 2

[0042] Weigh ZnSo 4 ·7H 2 o 3kg, anhydrous CaCl 2 1kg, 30kg of sorbitol, 30kg of lactose, 10kg of β-cyclodextrin and 1kg of sodium carboxymethyl cellulose, slowly add the above-mentioned substances to the concentrated solution of 400Kg (xylanase concentrated solution containing 55000u / g enzyme activity 200kg and 13330u / g cellulase concentrate), heated while stirring, and controlled the temperature to be less than 40°C. After all the solids were dissolved, the liquid was spray-dried to obtain xylan with an enzyme activity of 110000u / g 80Kg of soluble powder of cellulase enzyme and enzyme activity 25000u / g. This product is easily soluble at 5-10°C while stirring, and the solution is clear and transparent after dissolution.

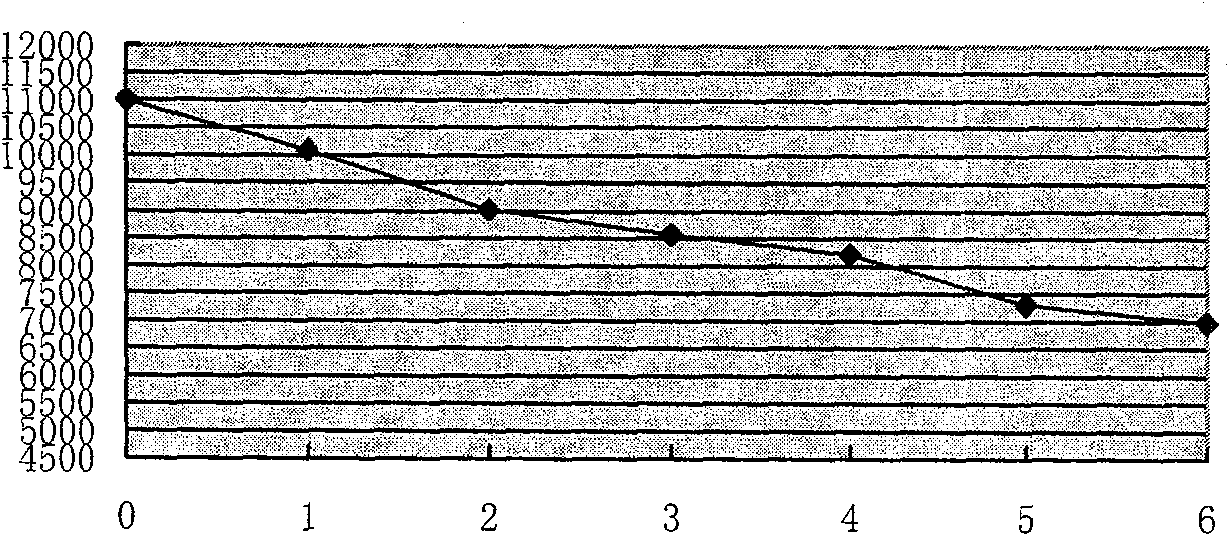

[0043] Figure 15 Shown is the stability analysis of the xylanase in this product stored at room temperature for 6 months. The analysis and calculation shows that the enzyme activity retention rate of xylanase in this product is 96% when stored at room ...

Embodiment 3

[0045] Weigh ZnSo 4 ·7H 2 o 6kg, anhydrous CaCl 2 3kg, 50kg of sorbitol, 50kg of lactose, 30kg of β-cyclodextrin and 5kg of sodium carboxymethyl cellulose, and slowly add the above-mentioned substances to the concentrated solution of 500Kg (the concentrated solution of xylanase containing 107276u / g enzyme activity 200kg, 200kg of cellulase concentrate with enzyme activity 27363u / g and 100kg of β-glucanase with enzyme activity 31606u / g), heat while stirring, and control the temperature to be less than 40°C. After all the solids are dissolved, it must contain 150Kg of soluble powder of xylanase with an enzyme activity of 115000u / g, cellulase with an enzyme activity of 27500u / g and β-glucanase with an enzyme activity of 18000u / g. This product is easily soluble at 5-10°C while stirring, and the solution is clear and transparent after dissolution.

[0046] Figure 19 Shown is the stability analysis of the xylanase in this product stored at room temperature for 6 months. The an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com