Leak detection tool applied to high pressure gas leak detection method

A high-pressure gas and leak detection technology, which is applied in the direction of detecting the appearance of fluid at the leak point, using liquid/vacuum degree to measure the liquid tightness, etc., can solve the problem of thread tightness inspection at the joint of the pipe string, which cannot be used on site, Can not ensure the sealing condition and other problems, to achieve the effect of simple and easy on-site operation, high detection reliability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

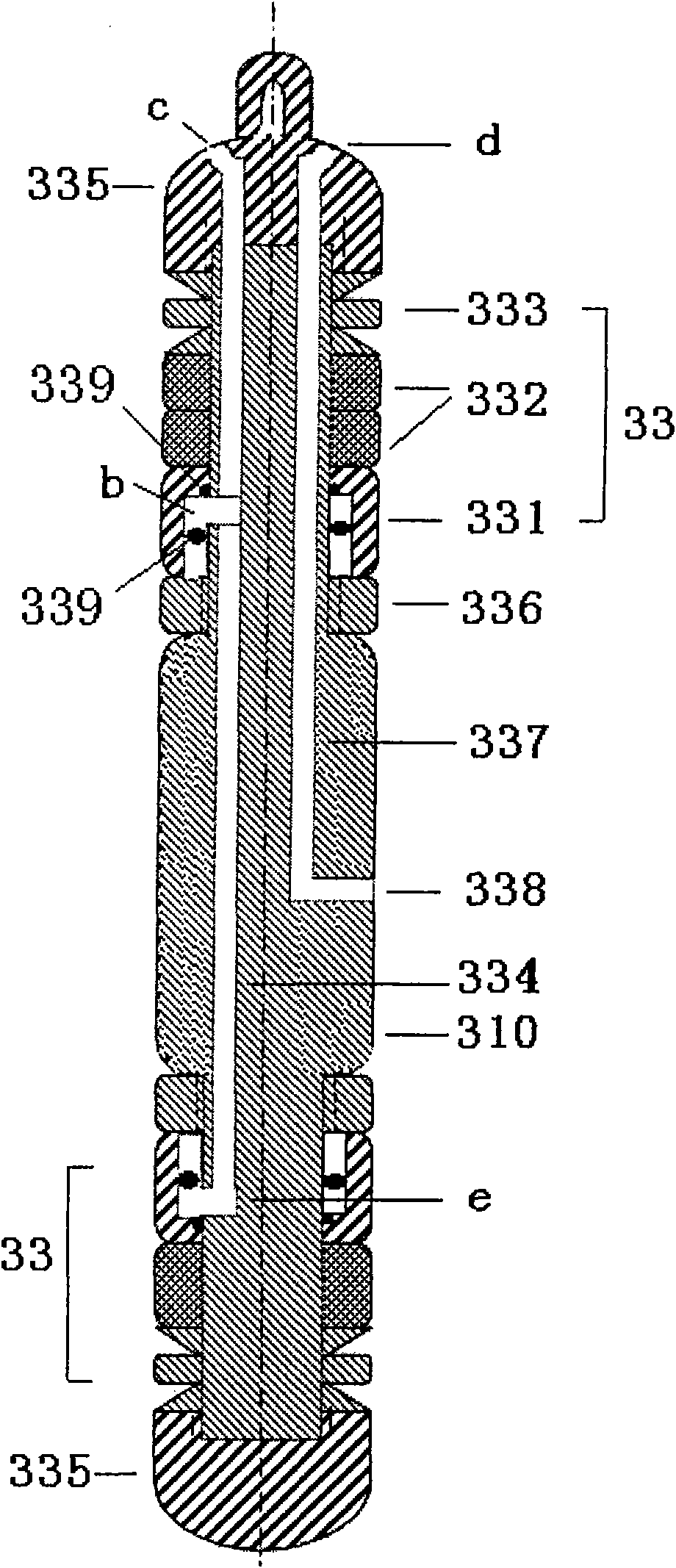

[0044] The leak detection tool used in the high-pressure gas leak detection method provided by the present invention includes a sealing tool and a detection gas collection sleeve. The two sides of the connecting screw buckle part that may leak are used to establish an inner airtight space that can be filled with detection gas, or an air-filled space; the detection gas collection sleeve is arranged outside the tubing string or casing string or auxiliary tools, Connect the thread buckle part that may leak, and cover the part to be leaked in the detection gas collection sleeve to establish an external closed space or detection space that can detect leakage; the inflatable space is provided with a high-pressure detection gas inlet, used It is connected with a device that generates high-pressure detection gas; the high-pressure detection gas enters the gas-filled space; and a gas detection instrument is connected to the detection space.

[0045] The device that can quickly generate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com