Method for preparing composite textile pulp by nanometer polymer emulsion

A technology of nano-polymers and polymer emulsions, which is applied in the fields of textiles, papermaking, and fiber processing, and can solve problems such as increased product costs, difficult problems of nano-particle agglomeration, and impacts on the promotion and application of nano-slurries, and achieves the goal of falling Less cotton, easy sizing and desizing, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The preparation method of nano polymer emulsion composite textile size, it comprises the following steps;

[0023] 1), the preparation of polymer emulsion: 10 milliliters of methyl methacrylate, 0.5g sodium dodecylbenzene sulfonate (emulsifier), 0.3g potassium persulfate (initiator), 100 milliliters of distilled water; At 80 degrees Celsius Stir evenly for 8 hours to obtain the desired polymer emulsion;

[0024] 2), the obtained polymer emulsion of step 1) will be directly used in this step reaction, add 0.8g paraffin in the system, 0.5g sodium hexametaphosphate and 3.0g nano silicon dioxide, and 60g modified starch (acid-thinned starch ); react at 80 degrees Celsius for 2 hours to obtain the target nanopolymer emulsion composite textile size.

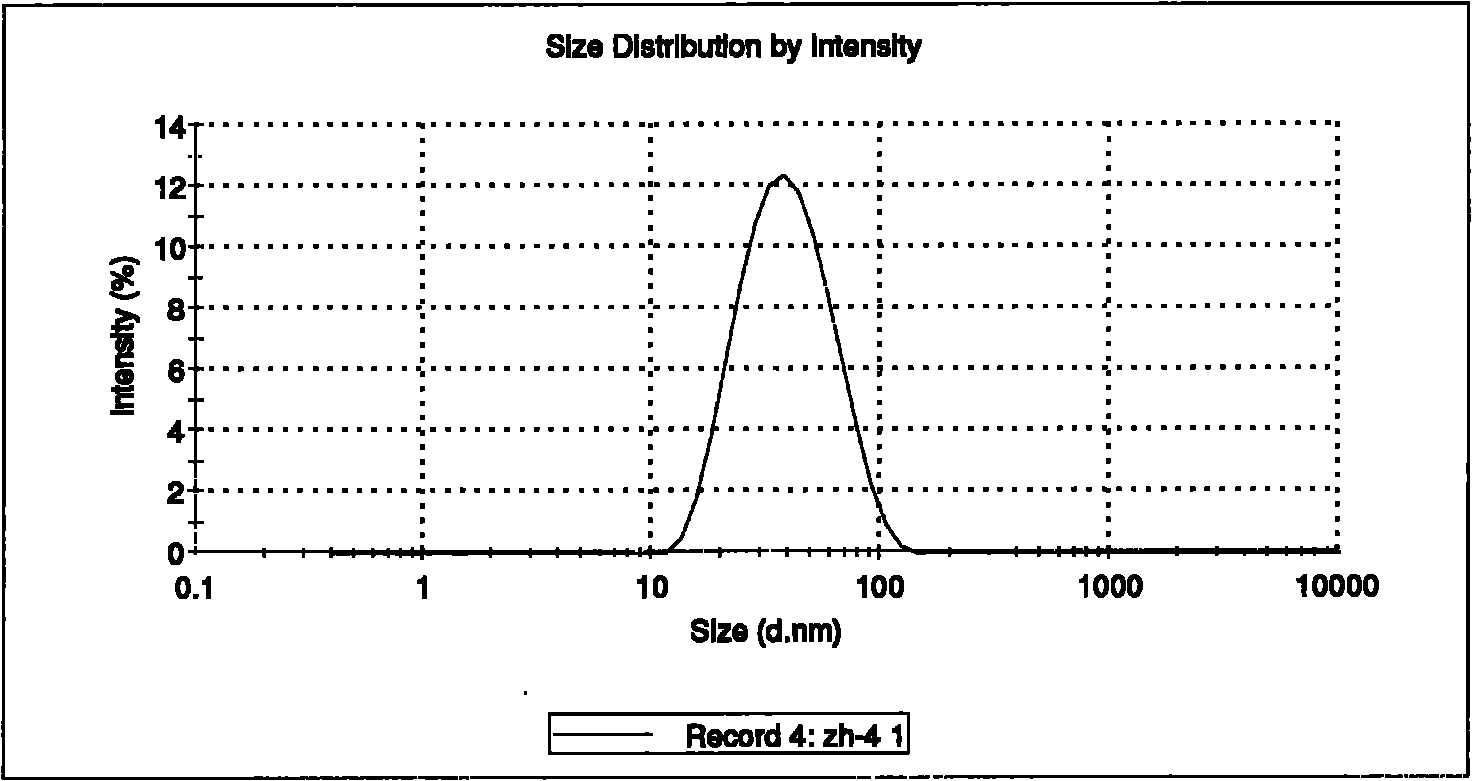

[0025] figure 1 is the particle size distribution, and the particle size is nanoscale; figure 2 is the particle size distribution, and the particle size is nanoscale.

Embodiment 2

[0027] The preparation method of nano polymer emulsion composite textile size, it comprises the following steps;

[0028] 1) Preparation of polymer emulsion: 10 milliliters of methyl methacrylate, 0.3 g sodium dodecylbenzenesulfonate (emulsifier), 0.5 g potassium persulfate (initiator), 100 milliliters of distilled water; After stirring for 8 hours, the required polymer emulsion can be obtained;

[0029] 2), the obtained polymer emulsion of step 1) will be directly used in this step reaction, add 0.6g paraffin in the system, 0.5g sodium hexametaphosphate and 2.0g nano silicon dioxide, and 40g modified starch (etherified starch ); react at 80 degrees Celsius for 2 hours to obtain the target nanopolymer emulsion composite starch slurry.

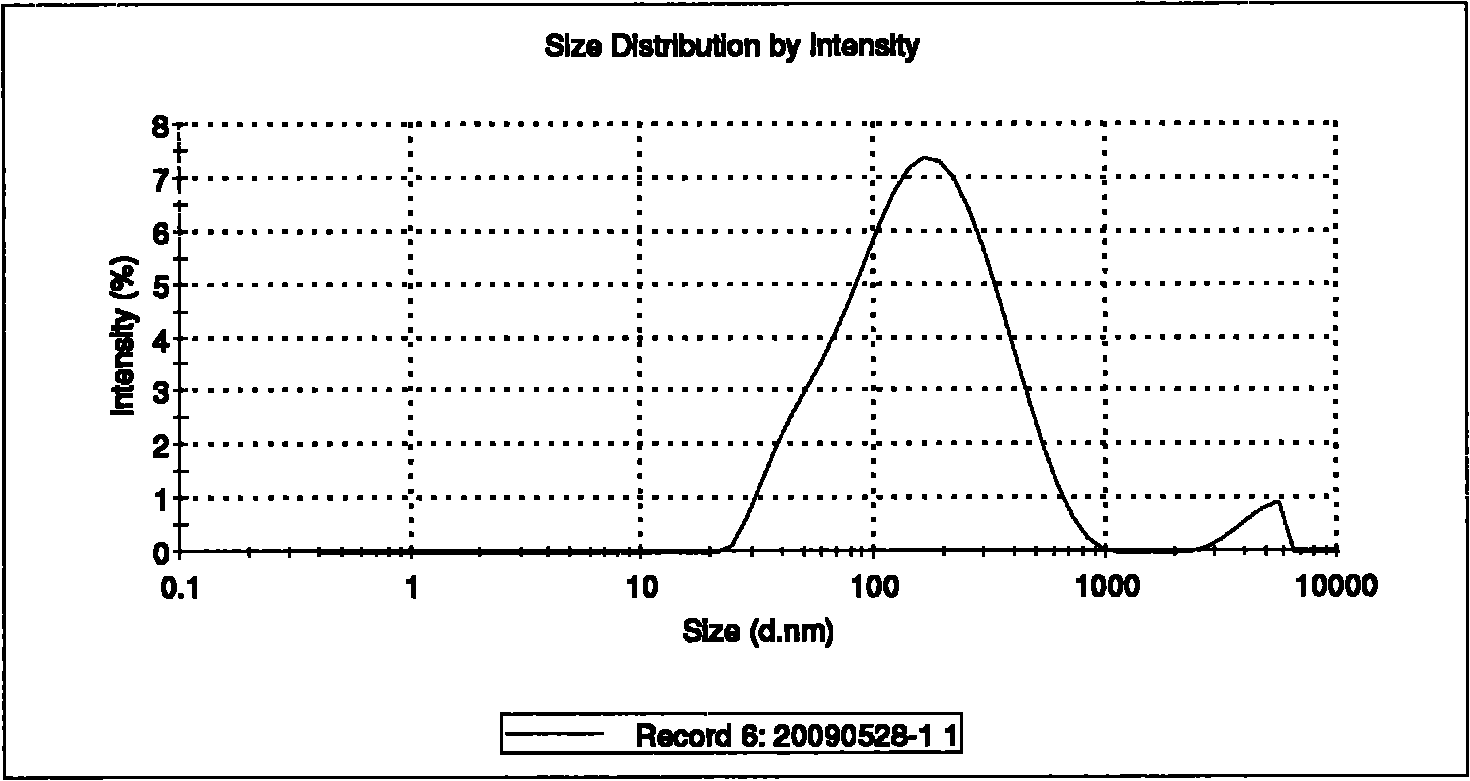

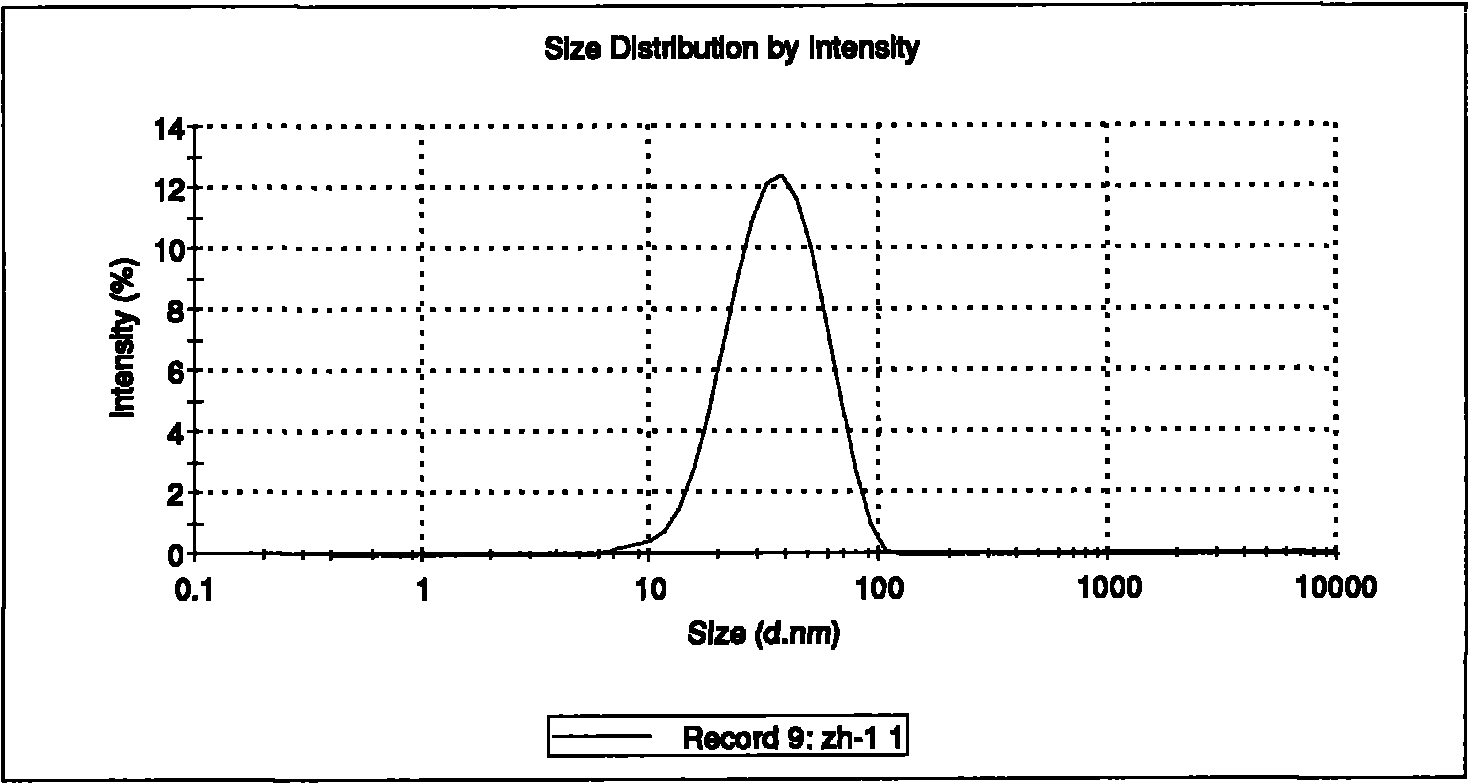

[0030] image 3 is the particle size distribution, and the particle size is nanoscale; Figure 4 is the particle size distribution, and the particle size is nanoscale.

Embodiment 3

[0032] The preparation method of nano polymer emulsion composite textile size, it comprises the following steps;

[0033] 1) Preparation of polymer emulsion: 10 milliliters of methyl methacrylate, 0.5 g sodium dodecylbenzenesulfonate, 0.3 g potassium persulfate, 60 milliliters of distilled water; uniformly stirred for 8 hours at 80 degrees Celsius to obtain the obtained The required polymer emulsion;

[0034] 2), the obtained polymer emulsion of step 1) will be directly used in this step reaction, add 0.3g paraffin in the system, 0.3g sodium hexametaphosphate and 1.0g nano silicon dioxide nano material, and 30g modified starch (acid Starch solution); reaction at 80 degrees Celsius for 2 hours to obtain the target nanopolymer emulsion composite starch slurry.

[0035] Figure 5 is the particle size distribution, and the particle size is nanoscale.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com