Biomass supercritical water gasification and multi-plate focusing heat supply coupling hydrogen production device and method

A supercritical water gasification and hydrogen production device technology, which is applied in the direction of heating devices, solar thermal devices, chemical instruments and methods, etc., can solve the problems of material corrosion product separation, high reaction temperature, technical difficulty, etc., and achieve the focus ratio Larger, lower reaction temperature, lower cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

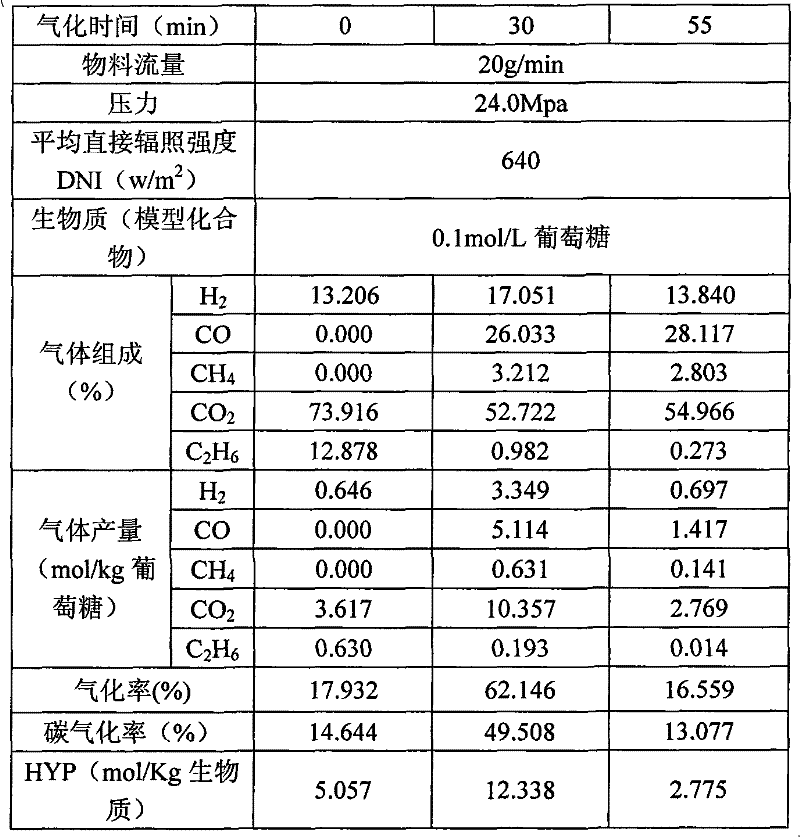

[0027] The gasification raw materials used in the present invention can be biomass model compounds (glucose, cellulose or lignin, etc.), primary biomass wastes (crop straws or various wastes, etc.), or industrial organic wastes. Hereinafter, the biomass model compound glucose is taken as an example for description.

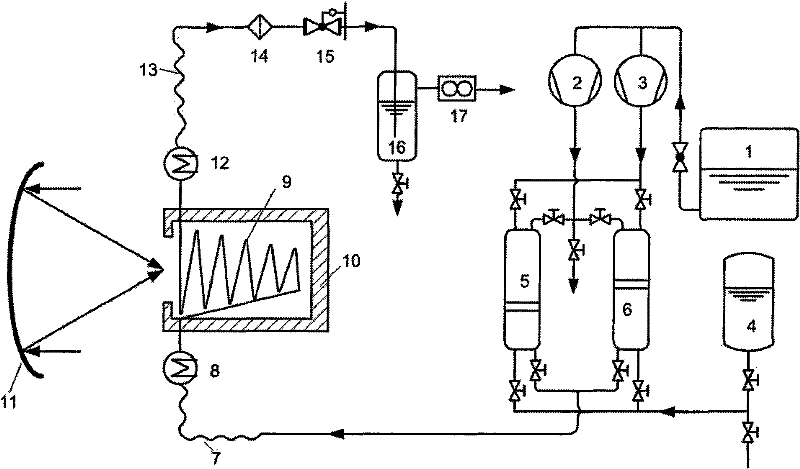

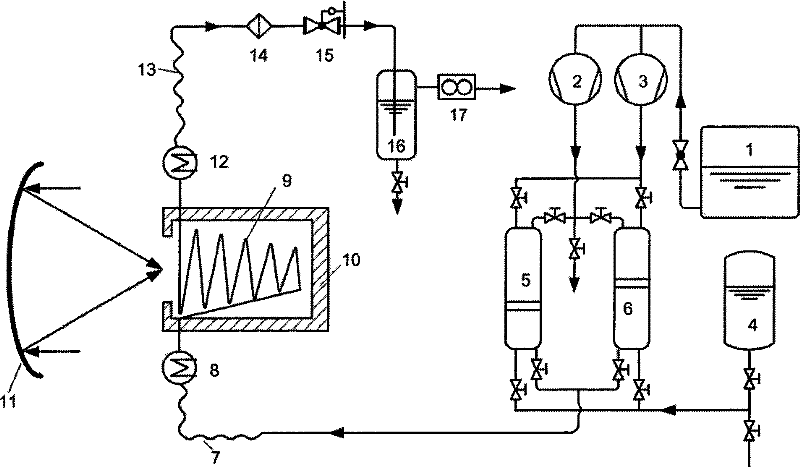

[0028] Refer to attached figure 1, in the device of the present invention, the first and second feeders 5,6, the first and second high-pressure plunger pumps 2,3, and the storage tank 4 communicate with each other through pipelines and valves to form a feeding system; the first feeder 5. The outlet of the second feeder 6 is connected to the inlet of the first metal hose; the outlet of the first metal hose 8 is connected to the inlet of the reactor; the outlet of the reactor 9 is connected to the inlet of the second cooler 12; the outlet of the second cooler 12 is connected to the inlet of the reactor The inlet of the second metal hose 13 is connected; the outlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com