Metal catalyst based on metal-organic framework as well as preparation method and application thereof

A technology of metal-organic frameworks and metal catalysts, applied in the direction of catalyst activation/preparation, organic compound/hydride/coordination complex catalysts, chemical instruments and methods, etc., can solve the problem of insufficient catalytic activity and catalytic hydrogen desorption not reaching the actual level Application needs and other issues, to achieve excellent catalytic properties, important innovation and application prospects, to promote the effect of interaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1, synthesis based on the Ni catalyst of MOF

[0026] (1) Dissolve nickel nitrate, 4,4'-bipyridine and 1,3,5-mellitic acid in DMF (N,N'-dimethylformamide) at a molar ratio of 1:1:1 In the process, the reaction was carried out for 72 hours at a temperature of 120°C, and the ligands and metal ions were coordinated to form MOF materials.

[0027] (2) Put the prepared MOF material into the reducing agent (NH 3 BH 3 ) (the molar ratio of reducing agent to MOF is 20:1), heated to 25°C, and reacted for 72 hours under anhydrous and oxygen-free conditions to obtain nanoscale MOF-based catalyst particles.

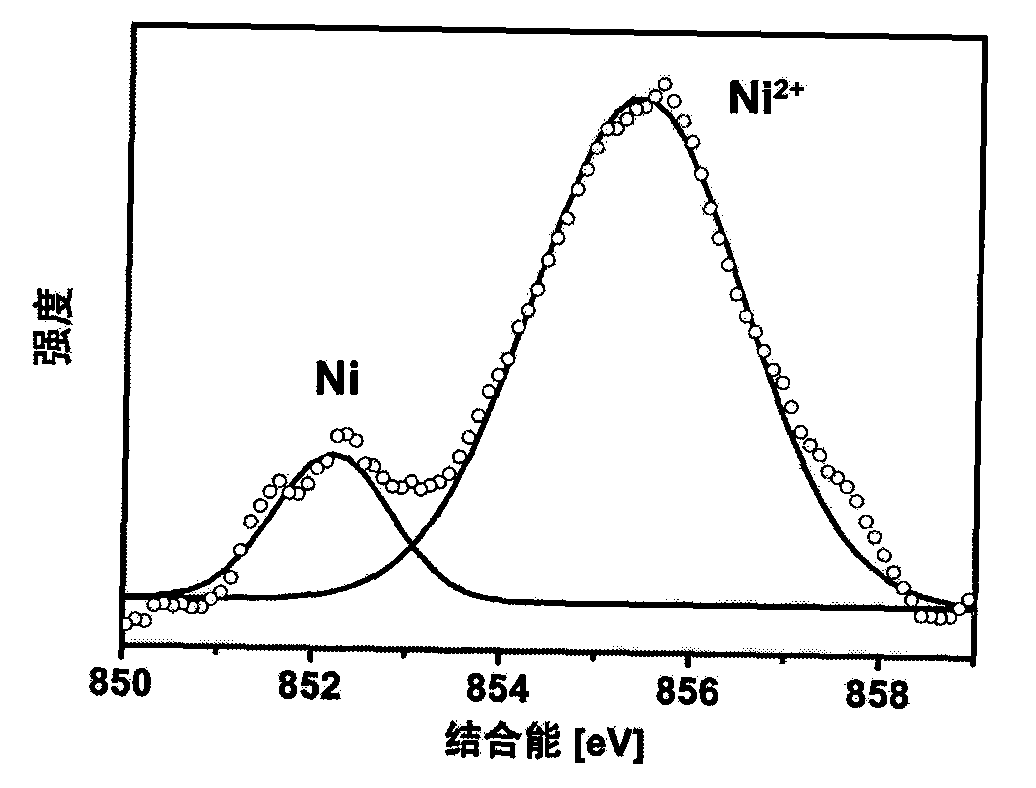

[0028] figure 1 The XPS (X-ray photoelectron spectroscopy) diagram of the MOF-based catalyst for the product of the above experiment shows that the prepared sample contains metal Ni reduced from the MOF (ie, the peak corresponding to 852.2eV).

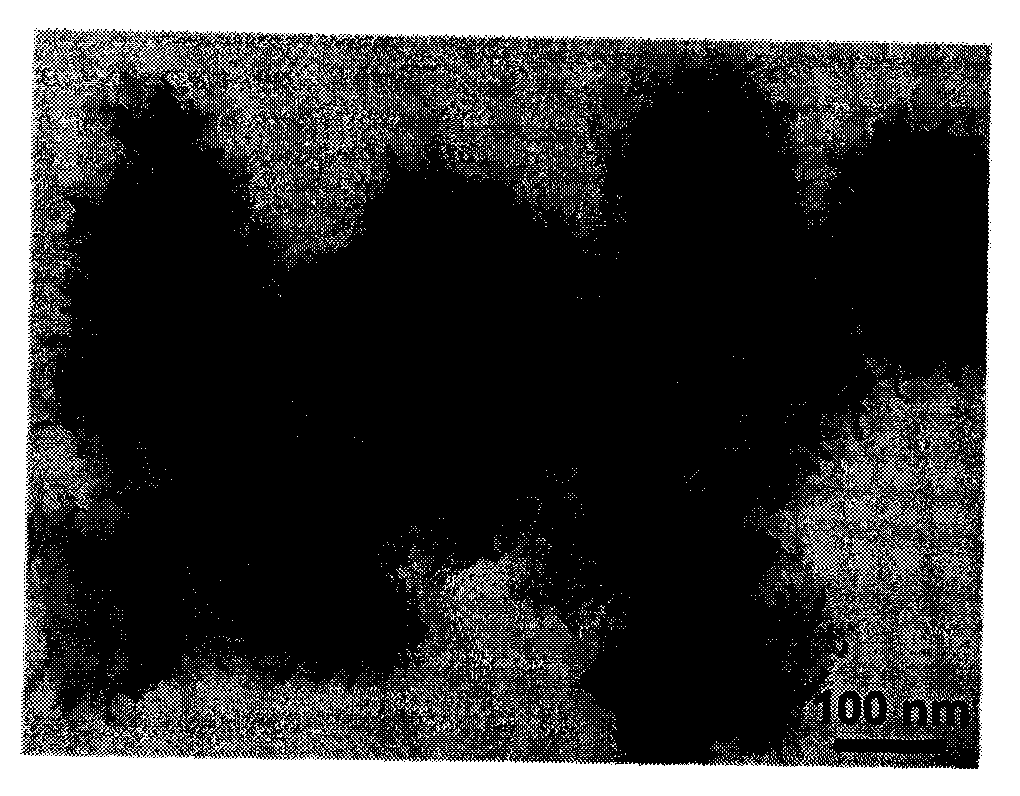

[0029] figure 2 The TEM (transmission electron microscope) image of the MOF-based catalyst particles of the above-me...

Embodiment 2

[0030] Embodiment 2, the catalyst based on MOF is used to catalyze NH 3 BH 3 Detection of the nature of hydrogen release from water

[0031] (1) The MOF-based catalyst prepared in Example 1 and 0.32M NH 3 BH 3 After the aqueous solution is mixed uniformly (wherein the catalyst concentration is 0.032M), it is placed in a volumetric hydrogen desorption device.

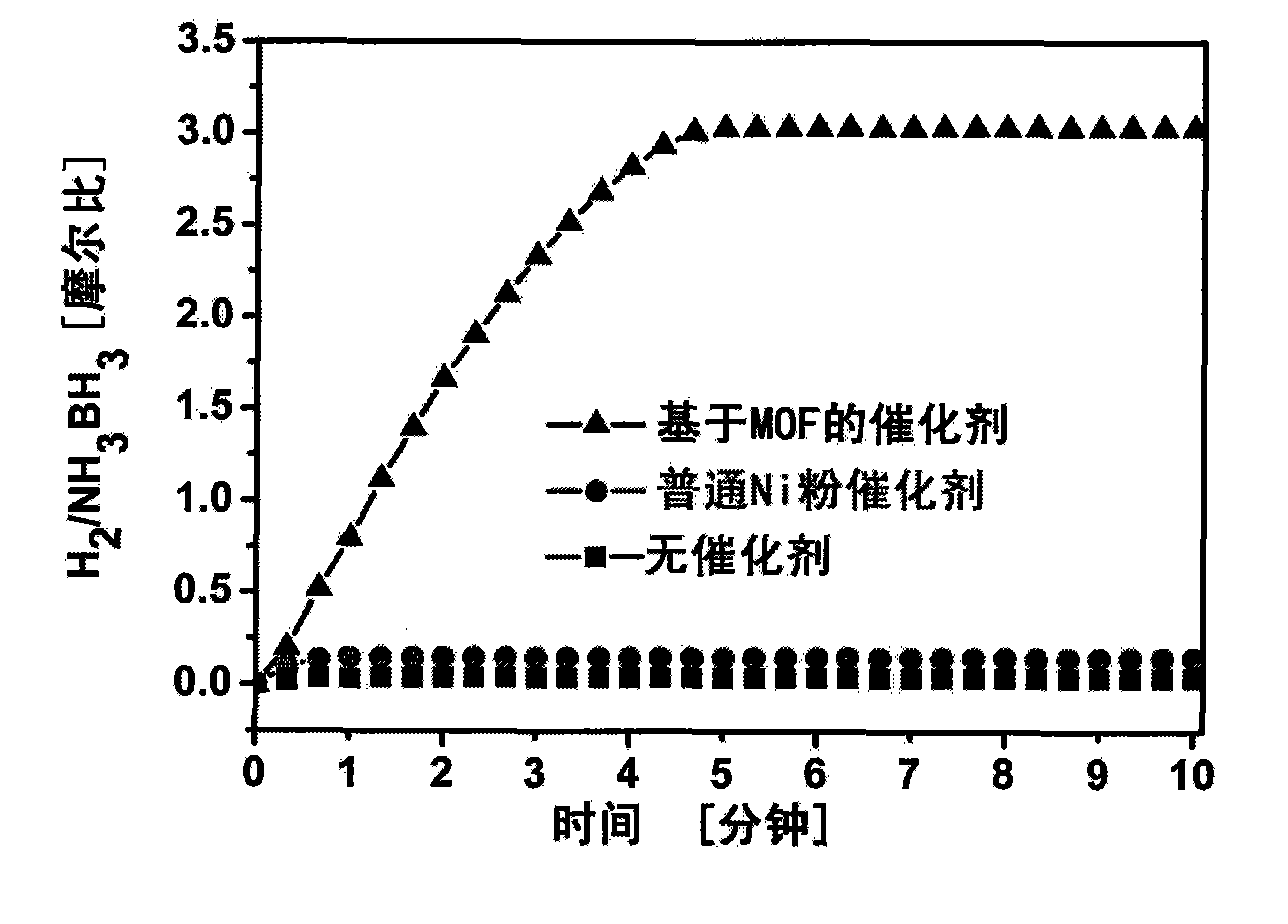

[0032] (2) At 25°C, measure its catalytic NH 3 BH 3 Hydrogen desorption property, its dehydrogenation kinetic curve is shown in image 3 . Depend on image 3 It can be seen that under the action of MOF-based catalyst, at 25 °C, NH 3 BH 3 The hydrogen contained within was completely released within 4.5 minutes. Among them, the amount of hydrogen released and NH 3 BH 3 The molar ratio reaches 3:1, and the hydrogen storage weight percentage reaches 8.9wt% (including the reacted NH 3 BH 3 and H 2 O). Depend on Figure 4 It can be seen that the activity of the catalyst did not show obvious decay within 20 cyc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com