Firing apparatus for a pyrotechnic protection apparatus

A technology for ignition equipment and protection equipment, which is applied to offensive equipment, weapon accessories, blasting cylinders, etc., can solve the problem of not being able to provide the pull-out force of pyrotechnic protection equipment, and achieve the effect of improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

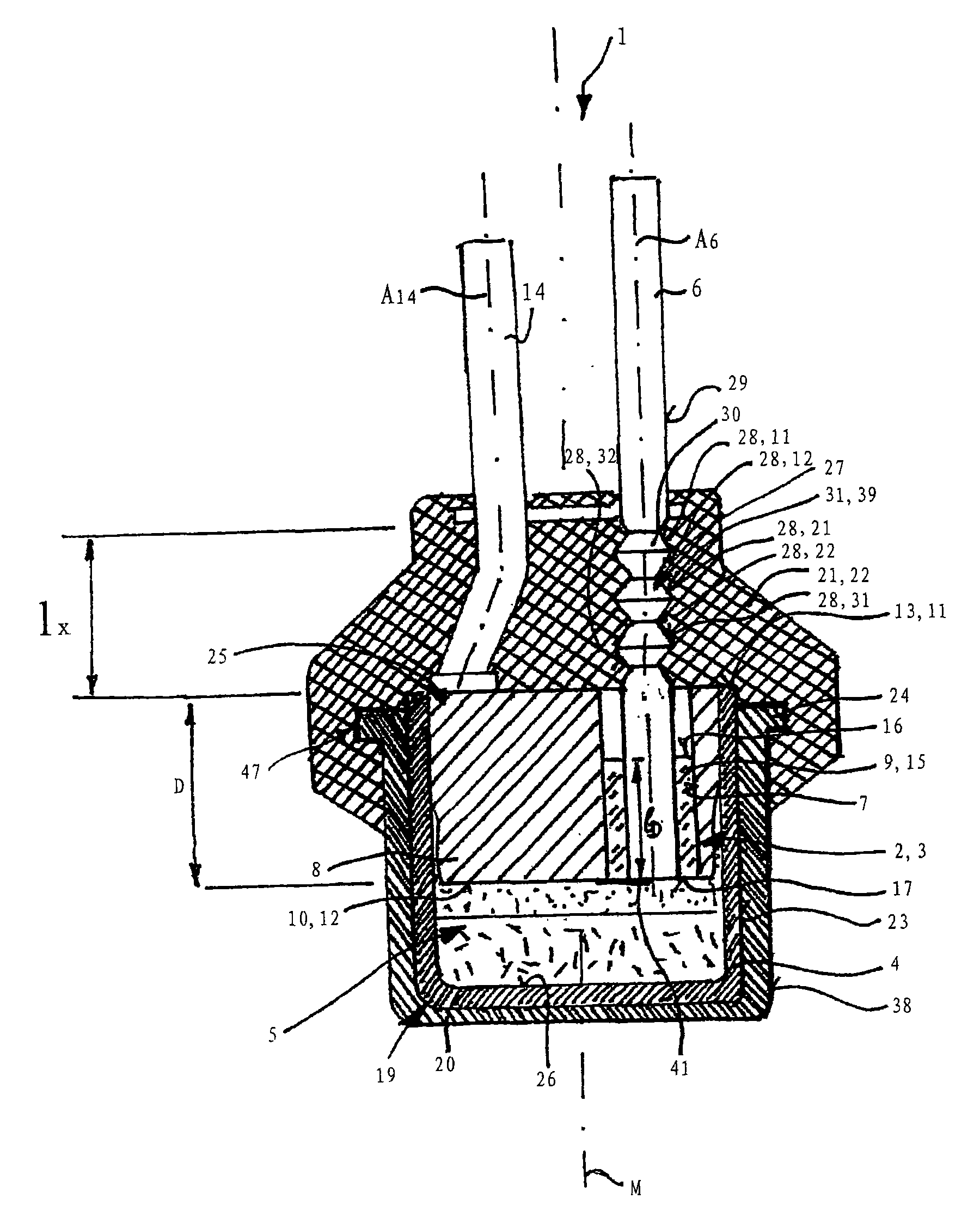

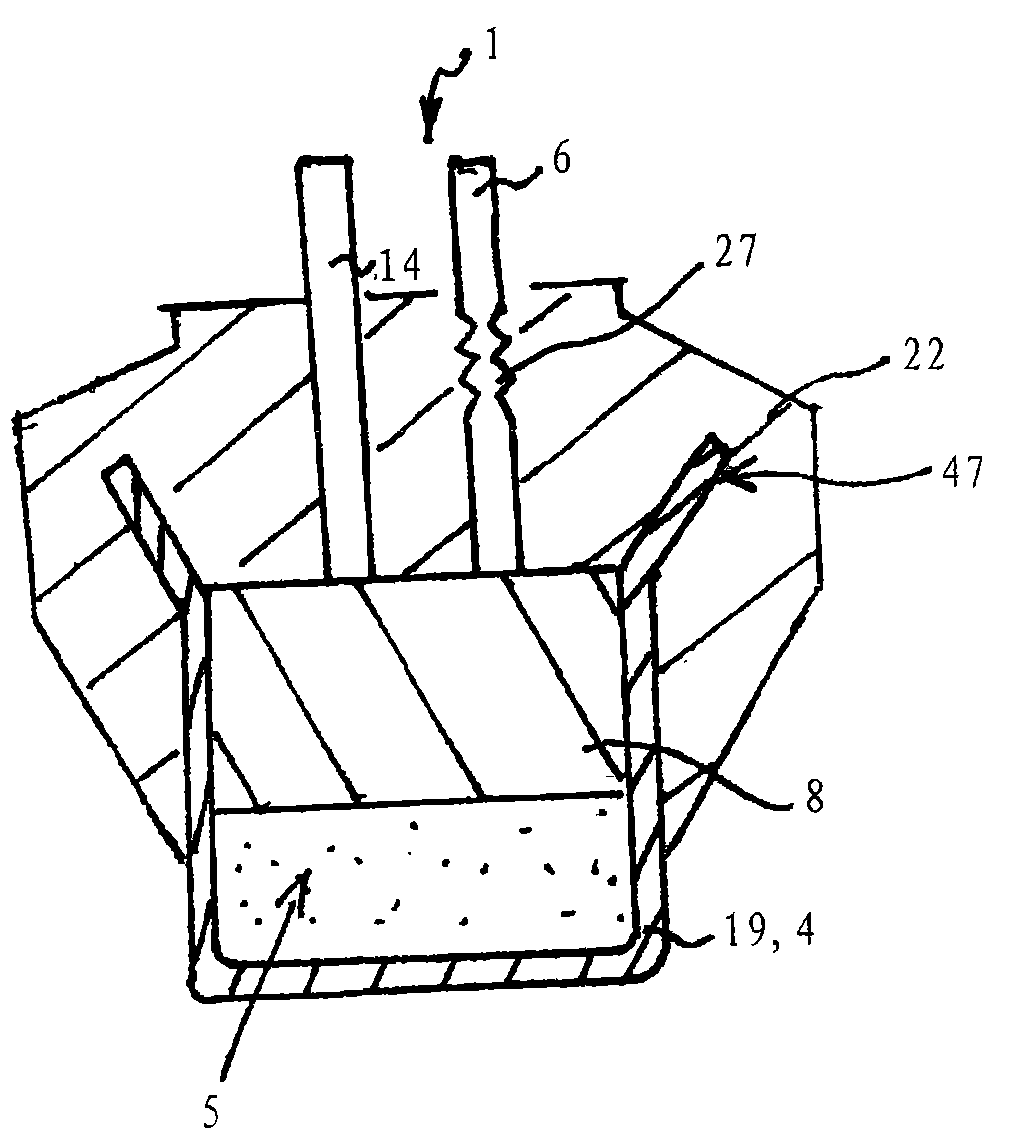

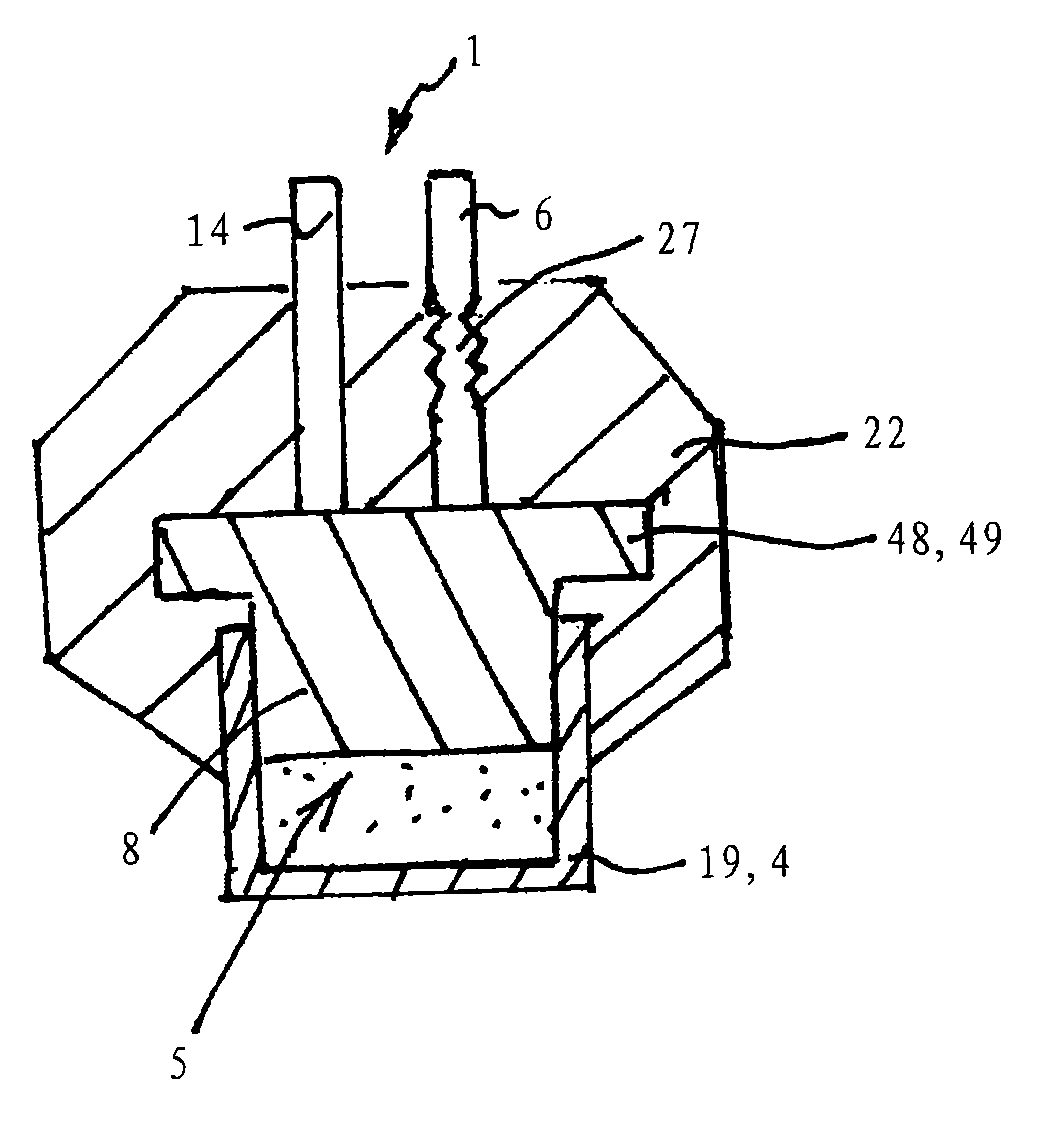

[0056] FIG. 1 shows an embodiment according to the invention of an ignition device 11 for a pyrotechnic protective device, in particular an airbag or a belt pretensioner, in an axial section in a schematically simplified illustration. The device comprises a current conducting bushing, in particular a metal-fixing material bushing 2, in particular in the form of a glass-metal bushing 3 for electronic ignition, and a metal-fixing material bushing 2 connected A cover 4 encloses a propellant charge 5 between the glass-metal insulating sleeve 2 and the cover 4 . The glass-metal insulating bushing 2 , in particular in the form of a glass-metal insulating bushing 2 , surrounds at least one metal pin 6 , which is melted in the base body 8 in the passage opening 7 in the fixing material 9 . The base body 3 here preferably has a disk-shaped basic shape and forms, with its end sides 10 and 11 , a front side 12 and a rear side 13 . The base body preferably has a thickness of from 0.1 mm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com