Preparation method of shallow trench isolation structure

A technology of isolation structure and shallow trench, applied in the field of preparation of shallow trench isolation structure, can solve the problems of electric field concentration, sharp silicon surface, slow surface oxidation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

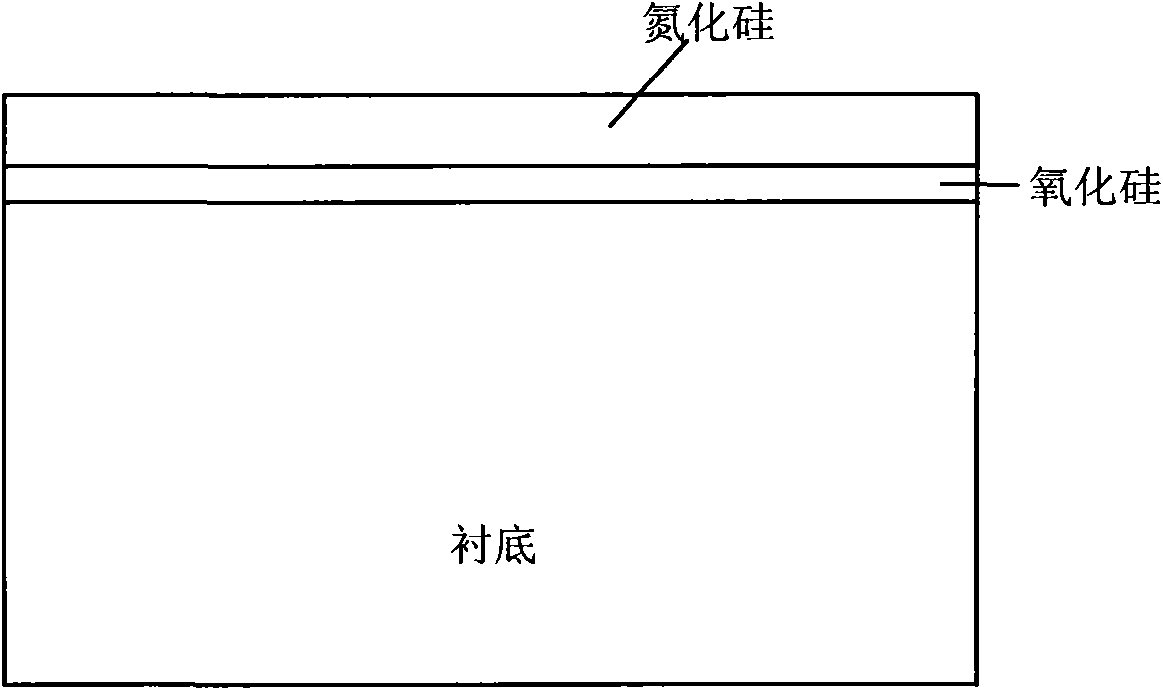

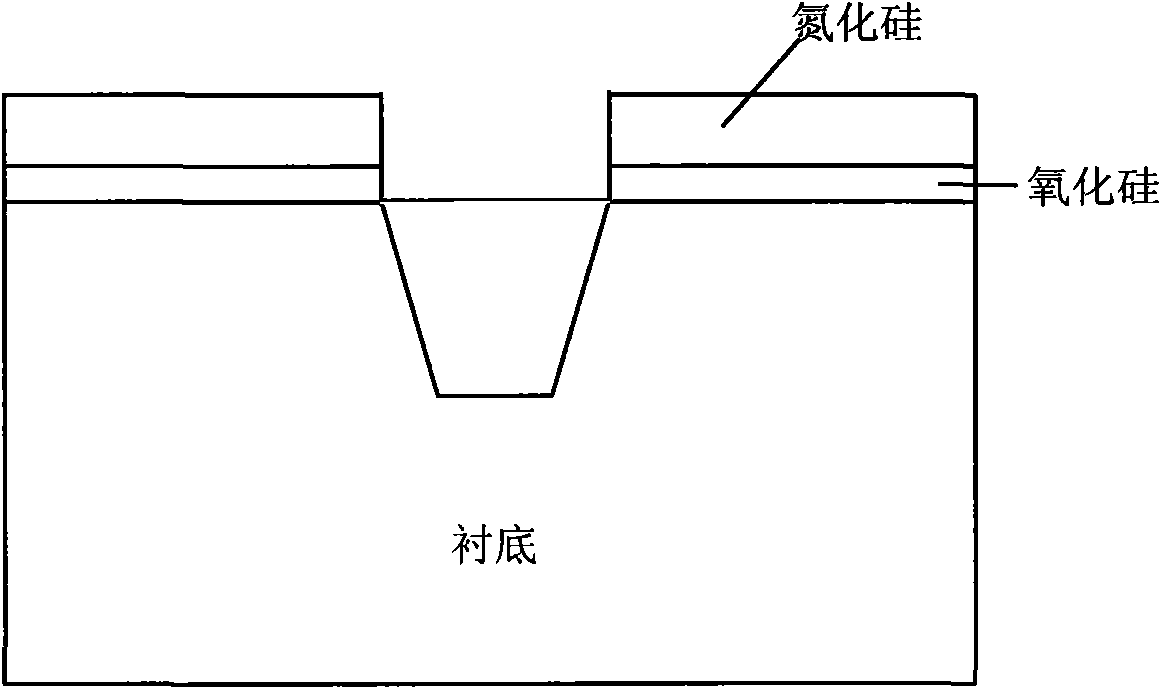

[0028] The preparation method of the shallow trench isolation structure of the present invention is integrated in the existing process, and mainly uses an etching process to etch to form a special silicon nitride morphology. The whole preparation process is as follows:

[0029] 1) Deposit silicon oxide and silicon nitride sequentially on a silicon substrate.

[0030] 2) Coating photoresist, performing shallow trench photolithography and developing, forming a photoresist opening. The specific settings in these two steps are similar to those in the prior art.

[0031] 3) Etching the silicon nitride by using the photoresist as a mask to remove part of the thickness of the silicon nitride, the thickness of the removed silicon nitride may be 20-60% of the total thickness of the silicon nitride layer;

[0032] 4) The lateral cutting of the photoresist, the opening of the photoresist in step 2 is enlarged by 10-50% (see Figure 7 ) This process can be carried out in the etching ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com