Control method for complete machine capability of variable-capacity multi-connected unit and control system therefor

A control method and multi-connection technology, applied in heating and ventilation control systems, heating and ventilation safety systems, refrigerators, etc., can solve the problems of variable-capacity multi-connection downtime and failure to satisfy users, and achieve good cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

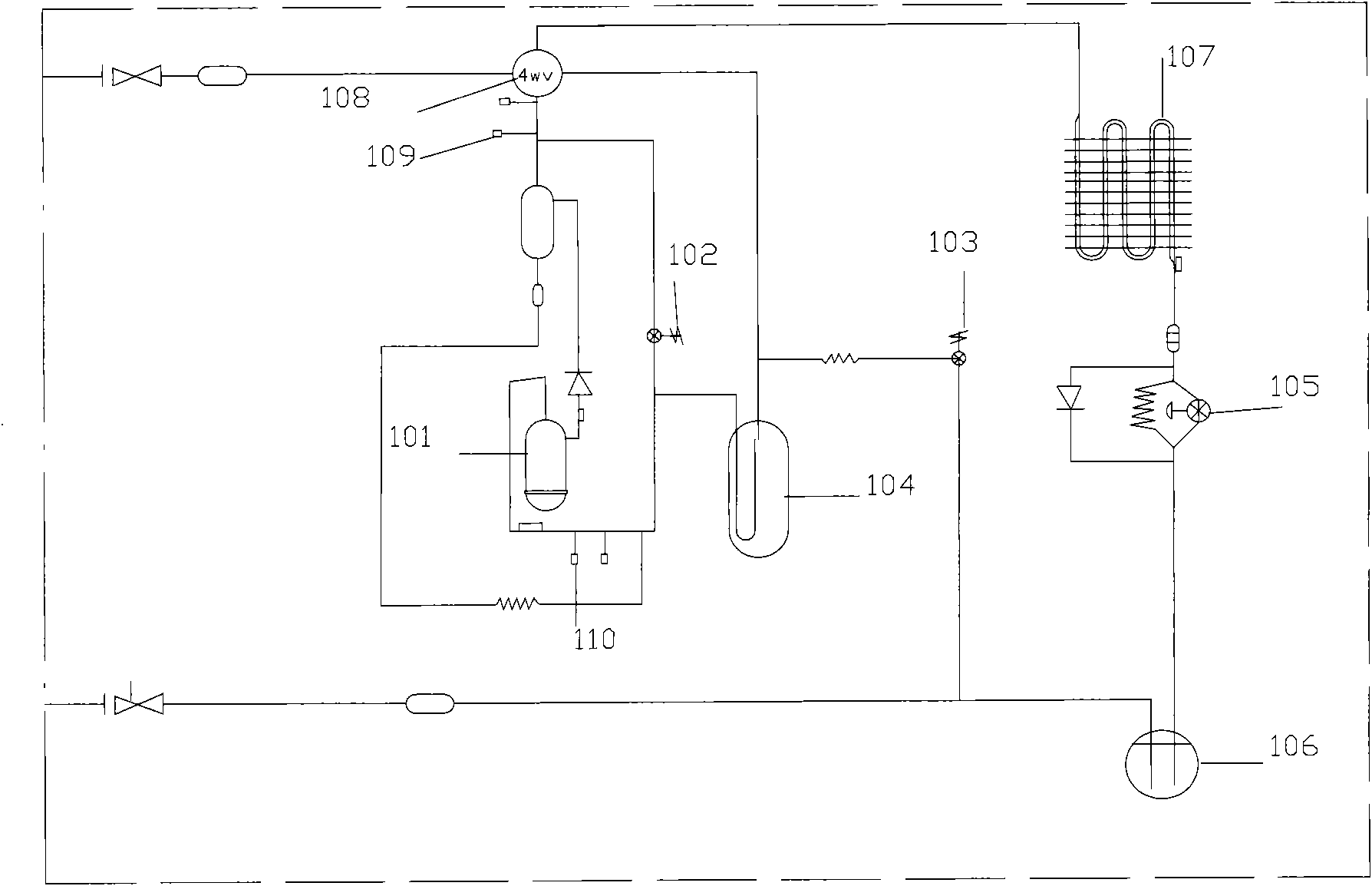

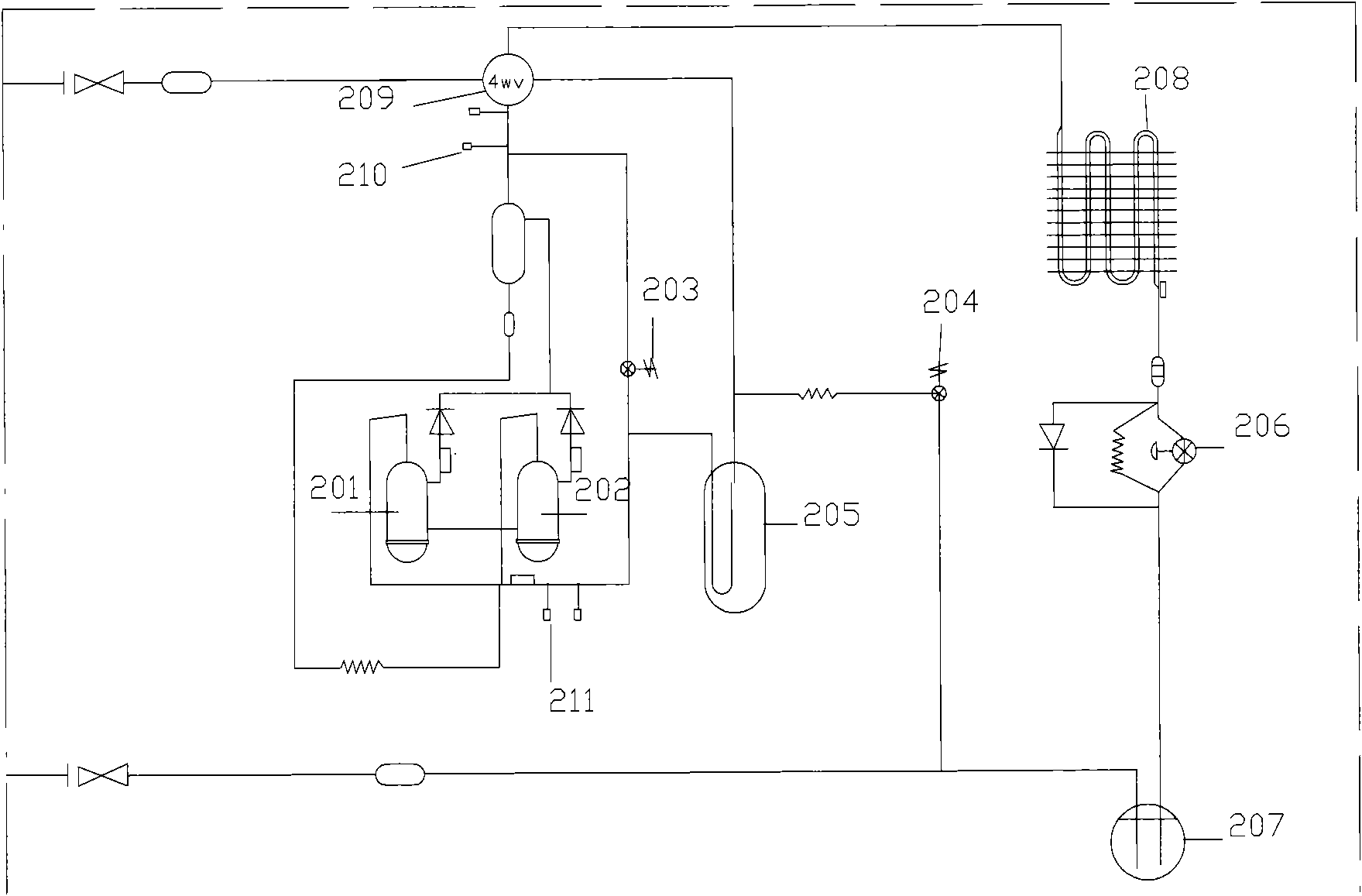

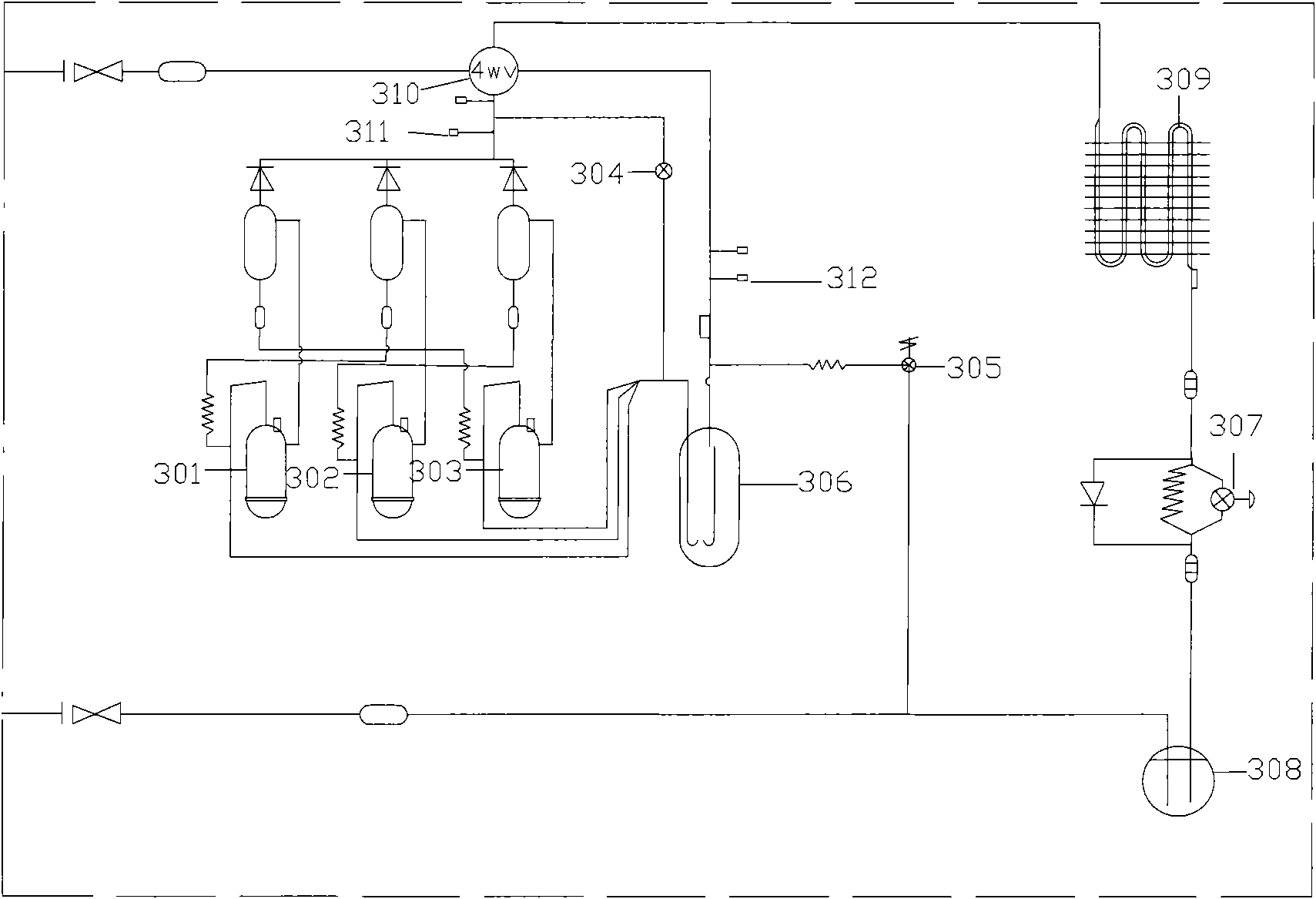

[0034] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0035] The variable capacity multi-line adopts single or multiple compressors, and a pressure relief valve and a liquid spray cooling valve are installed in the system. According to the ambient temperature and the load of the indoor unit, the number of compressors to be turned on is automatically adjusted; the exhaust pressure is monitored, and combined with the opening or closing of the pressure relief valve and the liquid spray cooling valve, the adjustment of the output of variable capacity and multi-connection capacity is realized. Due to the change of ambient temperature, the exhaust pressure is too high to cause the phenomenon of variable capacity multi-line alarm shutdown, so as to achieve good cooling and heating effects.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com