Heat supply system and heat supply method

A heating system and heat medium technology, applied in heating systems, hot water central heating systems, heating methods, etc., can solve the problems of existing technologies that cannot be used and lost, and achieve excellent economy, low cost, The effect of thermal efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

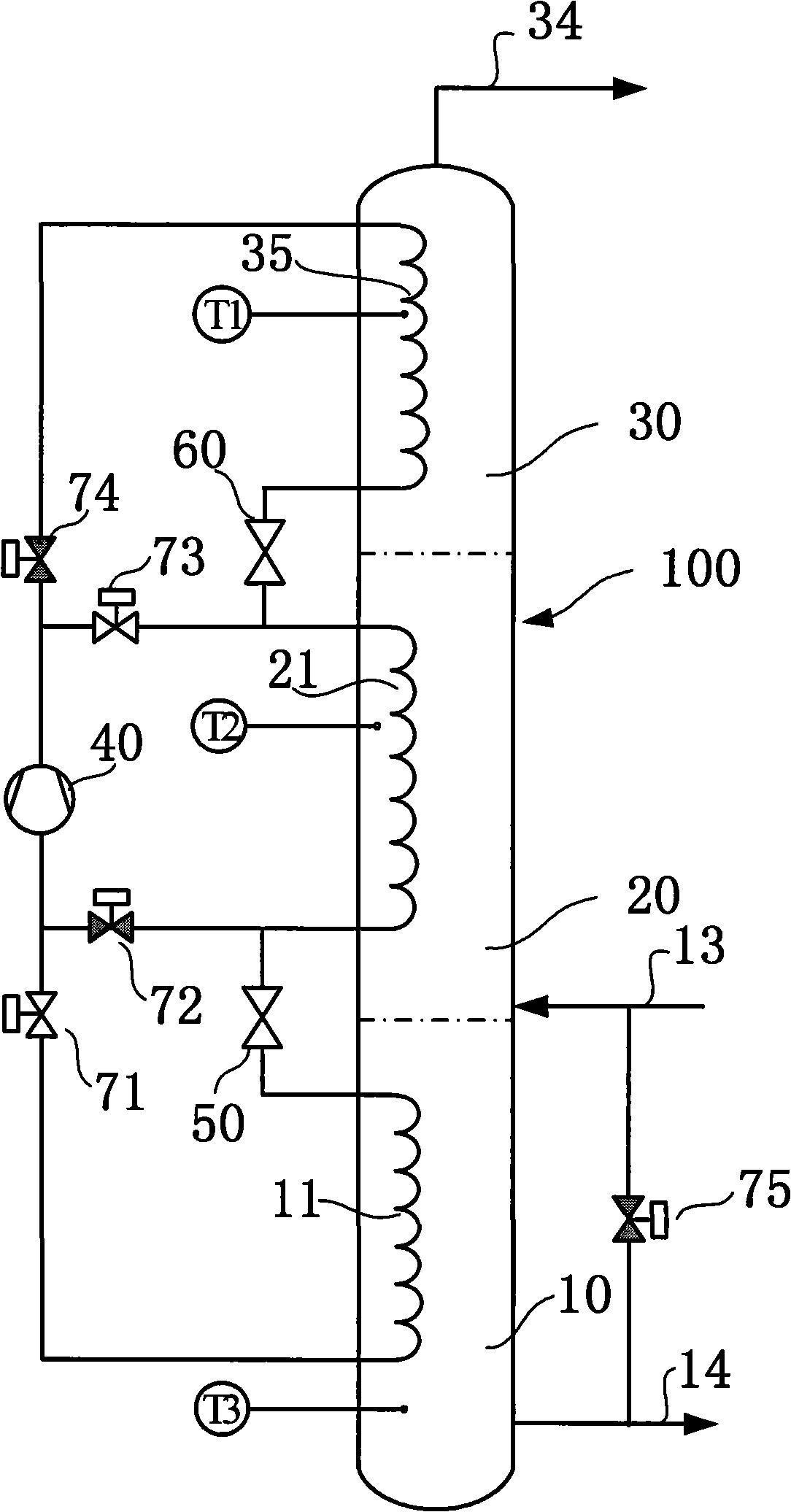

Image

Examples

example 1

[0046] Using the method of embodiment 4 to provide hot water, the ratio of the average flow of cold water to the average flow of hot water used by users is more than 12. The temperature of ambient air is 12°C, the temperature of tap water is 15°C, the temperature of hot water supplied from the top heat medium outlet is 50-55°C, with an average temperature of 52°C, and the average temperature of cold water supplied from the bottom heat medium outlet is 12°C . The average evaporation temperature of the first vapor compression heat pump cycle in this example is 7°C, the average condensation temperature is 40°C, the average evaporation temperature of the second vapor compression heat pump cycle is 30°C, and the average condensation temperature is 57°C. It is R22, the adiabatic efficiency of the compressor is 0.85, the comprehensive heat pump cycle COP of this example is 4.15, and the primary energy utilization efficiency is 137%.

example 2

[0048]Using the method of Embodiment 5 to provide hot water, the ratio of the average flow of cold water to the average flow of hot water used by users is more than 1. The ambient air temperature is 32°C, the temperature of the circulating working fluid of the condenser of the external refrigeration air conditioner is 40°C, the temperature of the tap water is 25°C, the temperature of the hot water provided from the top heat medium outlet is 50-55°C, and the average temperature is 52°C. The average temperature of the cool water supplied from the bottom heat medium outlet is 20°C. The average evaporation temperature of the first vapor compression heat pump cycle in this example is 15°C, the average condensation temperature is 40°C, the average evaporation temperature of the second vapor compression heat pump cycle is 30°C, and the average condensation temperature is 57°C. It is R22, the adiabatic efficiency of the compressor is 0.85, the comprehensive heat pump cycle COP of this...

example 3

[0050] Using the method of Embodiment 6 to provide hot water, the ratio of the average flow rate of cold water to the average flow rate of hot water used by users is more than 3. The ambient air temperature is 20°C, the temperature of tap water is 15°C, the temperature of hot water supplied from the top heat medium outlet is 53-58°C, with an average temperature of 55°C, and the average temperature of cold water supplied from the bottom heat medium outlet is 12°C . The heat storage agent of the first heat storage body adopts disodium hydrogen phosphate hydrate (Na 2 HPO 4 12H 2 O), the heat storage agent of the second heat storage body adopts sodium acetate hydrate (NaCH 3 COO·3H 2 O). The average evaporation temperature of the first vapor compression heat pump cycle in this example is 12°C, the average condensation temperature is 41°C, the average evaporation temperature of the second vapor compression heat pump cycle is 31°C, and the average condensation temperature is 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com