Parquet bamboo floor block formed by excess stock and manufacturing method thereof

A manufacturing method and a technology of floor boards, which are applied in manufacturing tools, building structures, floors, etc., can solve the problems of failure to meet the environmental protection requirements of home decoration, waste, economic loss, etc. The effect of high adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

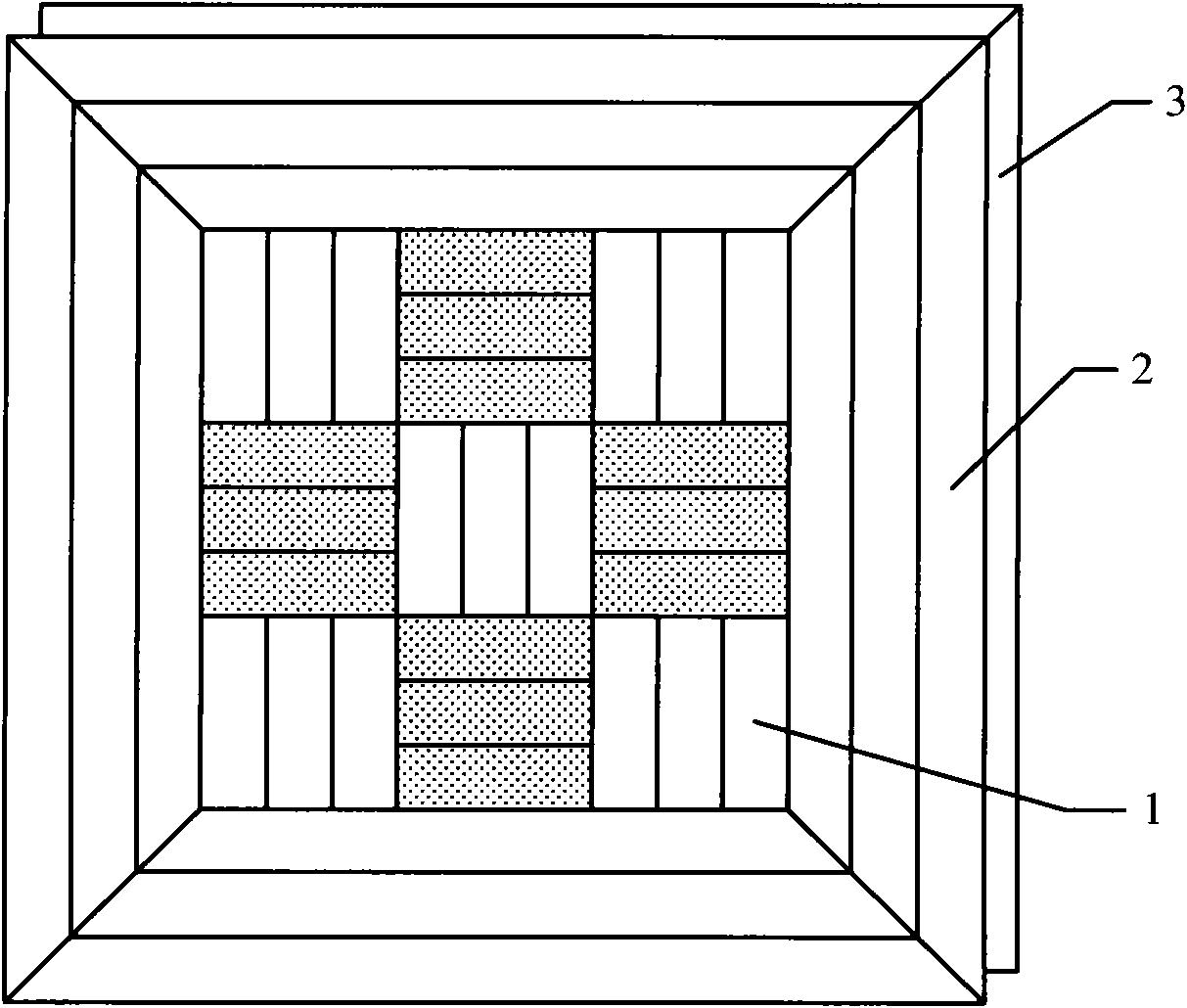

[0032] A mosaic bamboo floor board composed of leftover materials, the production process of which is as follows: firstly, cut the leftover materials of the bamboo floor board into bamboo veneers with required lengths of unit block 1 and frame 2 respectively. Specifically, the length of the bamboo veneer constituting the unit block 1 is 5.5 cm, and the length of the bamboo veneer constituting the frame 2 is 16.5 cm. Subsequently, the burrs on the outer surface of the above-mentioned bamboo veneer are cut off with a planer, while making the width and thickness of the bamboo veneer meet the requirements, that is, the thickness of the bamboo veneer is 0.3cm, and the width is 1.5cm. Next, stack the three-layer bamboo veneer of unit block 1 from top to bottom, arrange three groups, heat to 160°C, and use vertical pressing equipment to press under a pressure of 14 MPa for 5 minutes to form a composite Unit block 1. Next, the nine unit blocks 1 are spliced with each other in such ...

Embodiment 2

[0035]A mosaic bamboo floor board composed of leftover materials can be advanced processed and manufactured by the following method: first, the leftover materials of the bamboo floor board are cut into bamboo veneers of the required length for unit block 1 and frame 2 respectively, and then The length of the bamboo veneer constituting the unit block 1 is cut to 6.5 cm, and the length of the bamboo veneer constituting the frame 2 is cut to 30 cm.

[0036] Then, the burrs on the outer surface of the bamboo veneer are removed by a planer, during which the width of the bamboo veneer reaches 0.6 cm and the thickness is controlled within 2 cm. Next, stack the three-layer bamboo veneer of unit block 1 from top to bottom and arrange three groups, heat to 230°C, and use a vertical pressing device to press under a pressure of 21 MPa for 15 minutes to form a composite. Unit block 1.

[0037] Next, the nine unit blocks 1 are spliced with each other in such a way that the direction of t...

Embodiment 3

[0041] A mosaic bamboo floor board composed of leftover materials, the processing method is as follows: firstly, the leftover materials of the bamboo floor board are cut into bamboo veneers with required lengths of the unit block 1 and the frame 2 respectively. Specifically, the length of the bamboo veneer constituting the unit block 1 is 6 cm, and the length of the bamboo veneer constituting the frame 2 is 20 cm. Subsequently, the burrs on the outer surface of the above-mentioned bamboo veneer are cut off with a planer, while making the width and thickness of the bamboo veneer meet the requirements, that is, the thickness of the bamboo veneer is 0.5cm, and the width is 1cm.

[0042] Next, the three layers of bamboo veneers used to prepare the unit block 1 were stacked from top to bottom, arranged in three groups at the same time, heated to 200°C, and made into multi-layer bamboo veneers by vertical pressing equipment. Then at least three sets of multi-layer bamboo veneers are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com