Method for producing white carbon black by using high alumina fly ash and system thereof

A technology of high-aluminum fly ash and white carbon black, which is applied in the fields of chemical industry and materials, can solve the problems of difficult control of reaction process conditions, high energy consumption, and many production steps, so as to alleviate the shortage of aluminum resources, save production costs, and reduce The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

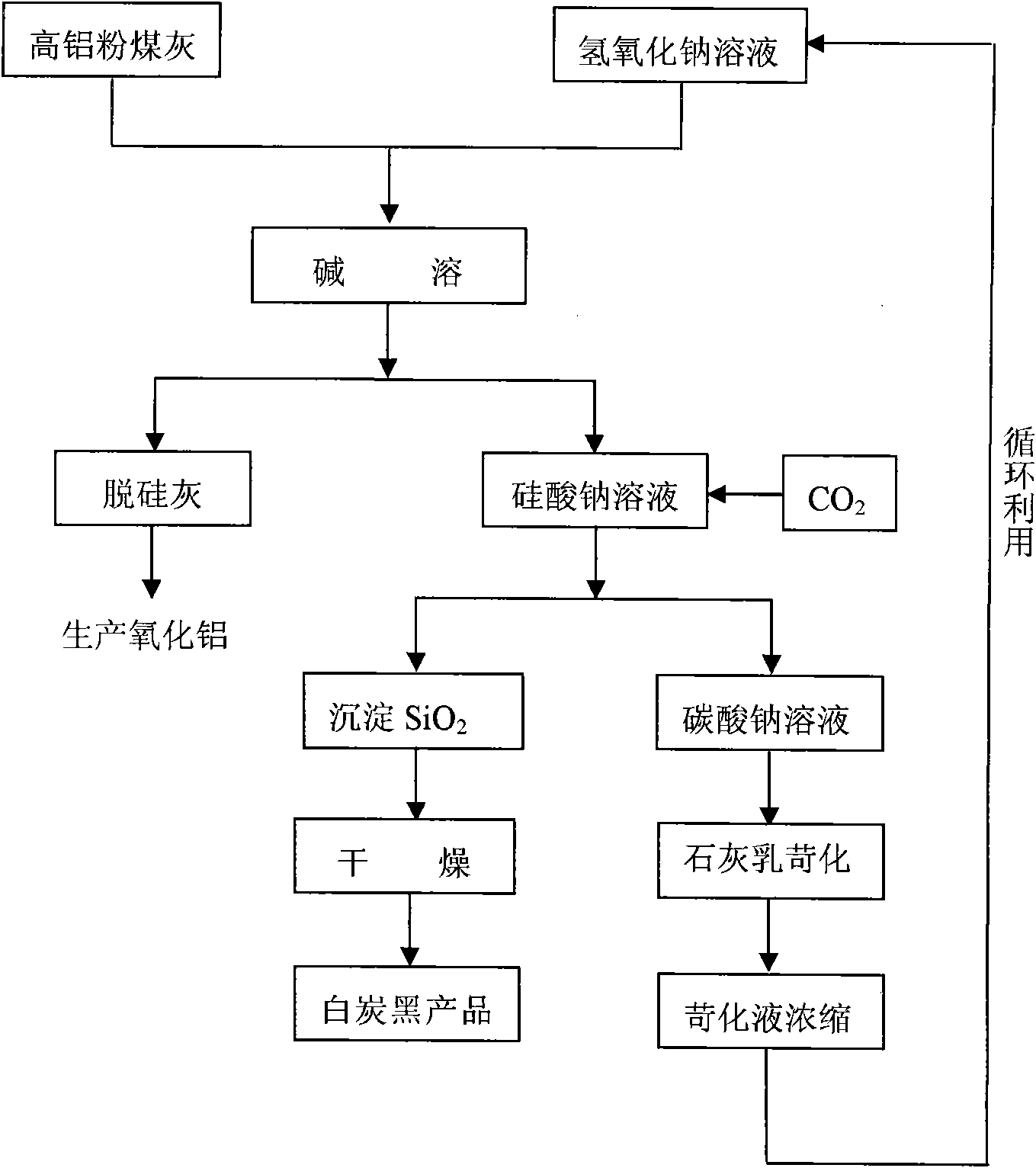

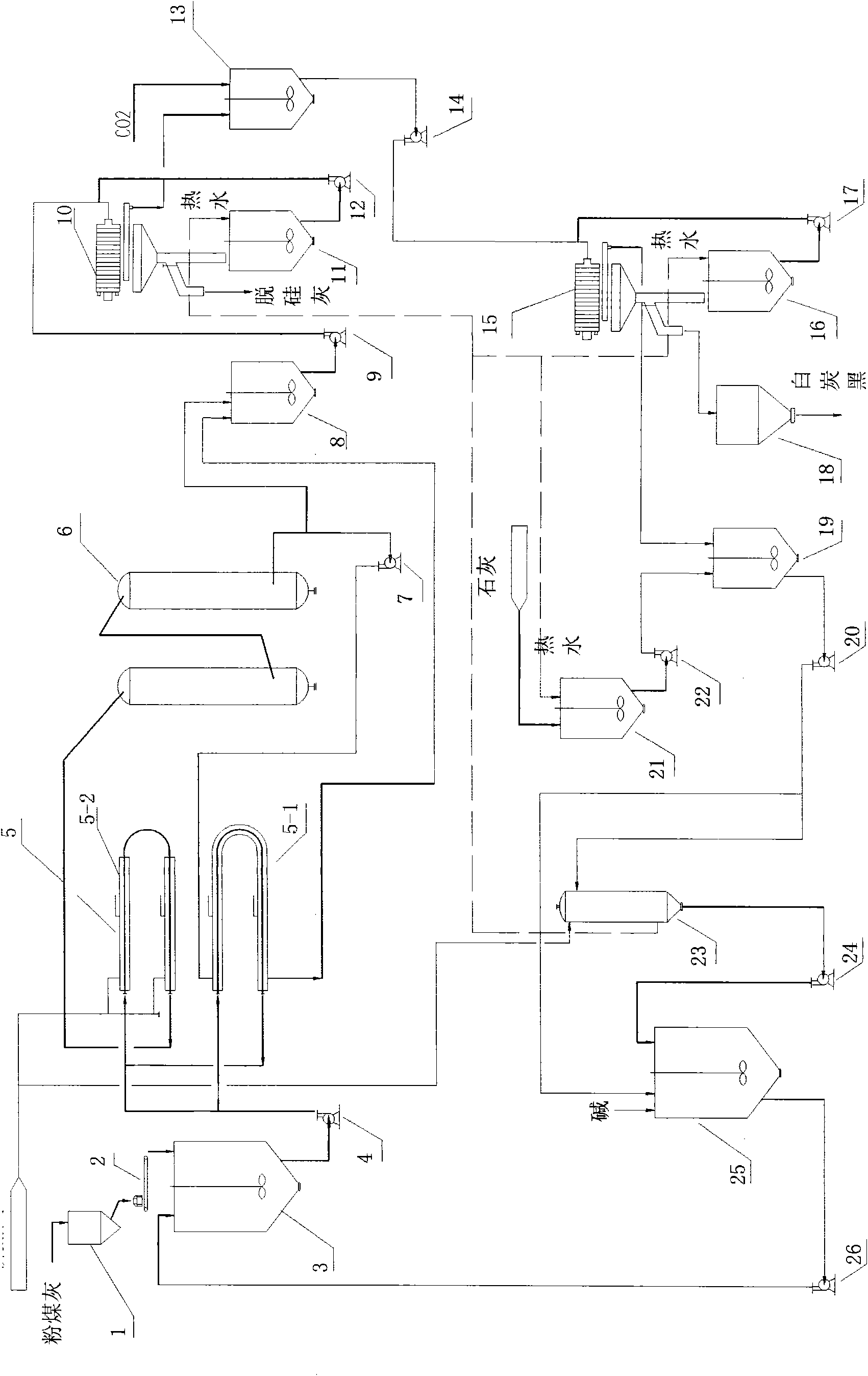

[0030] see figure 2 , the system of the present invention comprises a fly ash slurry preparation composed of a fly ash bin 1, a quantitative feeder 2, a fly ash slurry preparation tank 3, a desiliconization feeding liquid pump 4, a circulating mother liquid preparation tank 25 and a circulating mother liquid pump 26 System; consists of casing heater 5, heat preservation tank 6, desiliconization circulating pump 7, desiliconization slurry storage tank 8, filter feeding pump 9, flat disc filter 10, desiliconization ash filter cake tank 11 and desiliconization Fly ash pre-desilication system composed of silica fume filter cake pump 12; carbonization tank 13, filter press feed pump 14, plate and frame filter press 15, white carbon black filter cake tank 16, white carbon black filter cake The white carbon black preparation system that pump 17 and drier 18 are formed; And be made up of lime milk tank 21, lime milk pump 22, causticizing tank 19, causticizing liquid pump 20, tubular ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com