Microwave oven having metal sub-wavelength structure

A sub-wavelength structure and microwave oven technology, which is applied in microwave heating, household appliances, household stoves/stoves, etc., can solve problems such as conflicts, achieve uniform spatial distribution, and improve uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

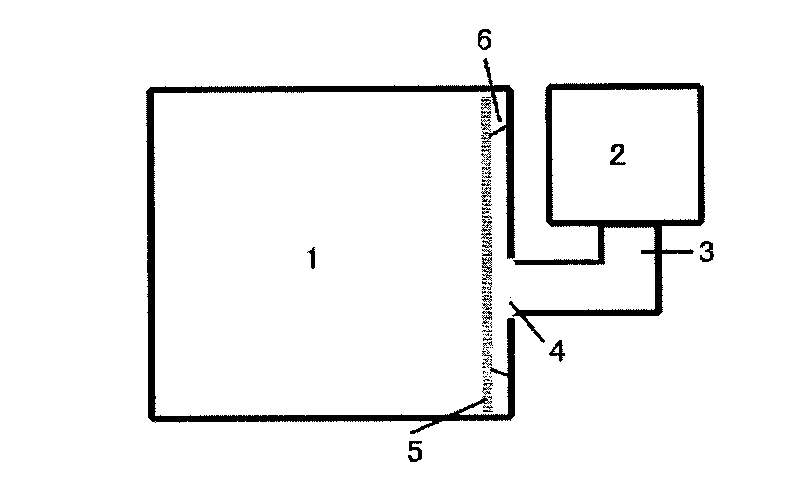

[0033] Microwave ovens designed according to the subwavelength structure are designed and manufactured using the following steps:

[0034] step 1:

[0035] Simulate metal subwavelength structures to determine periodic structures and structure dimensions on dielectric plates. The material properties such as the size of the metal subwavelength structure, the loss of the metal and the dielectric plate need to be considered in the simulation. Adjust the simulation parameters so that the microwave energy can pass through the metal sub-wavelength structure on the dielectric plate with low loss, without affecting the microwave use and absorption of the load, and at the same time obtain a relatively uniform microwave field distribution.

[0036] Step 2:

[0037] According to the simulation result of step 1, the metal subwavelength structure is fabricated on the dielectric plate by using the optimized structure parameters. Metal subwavelength structures can be fabricated by methods ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com