LED optical-concentrated device in direct impact mode

A hedging, light-collecting technology, applied to lighting devices, lighting device parts, light sources, etc., can solve the problems of failing to achieve lighting effects, failing to reflect light, wasting the maximum energy of the light source, etc. The effect of improving light efficiency and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

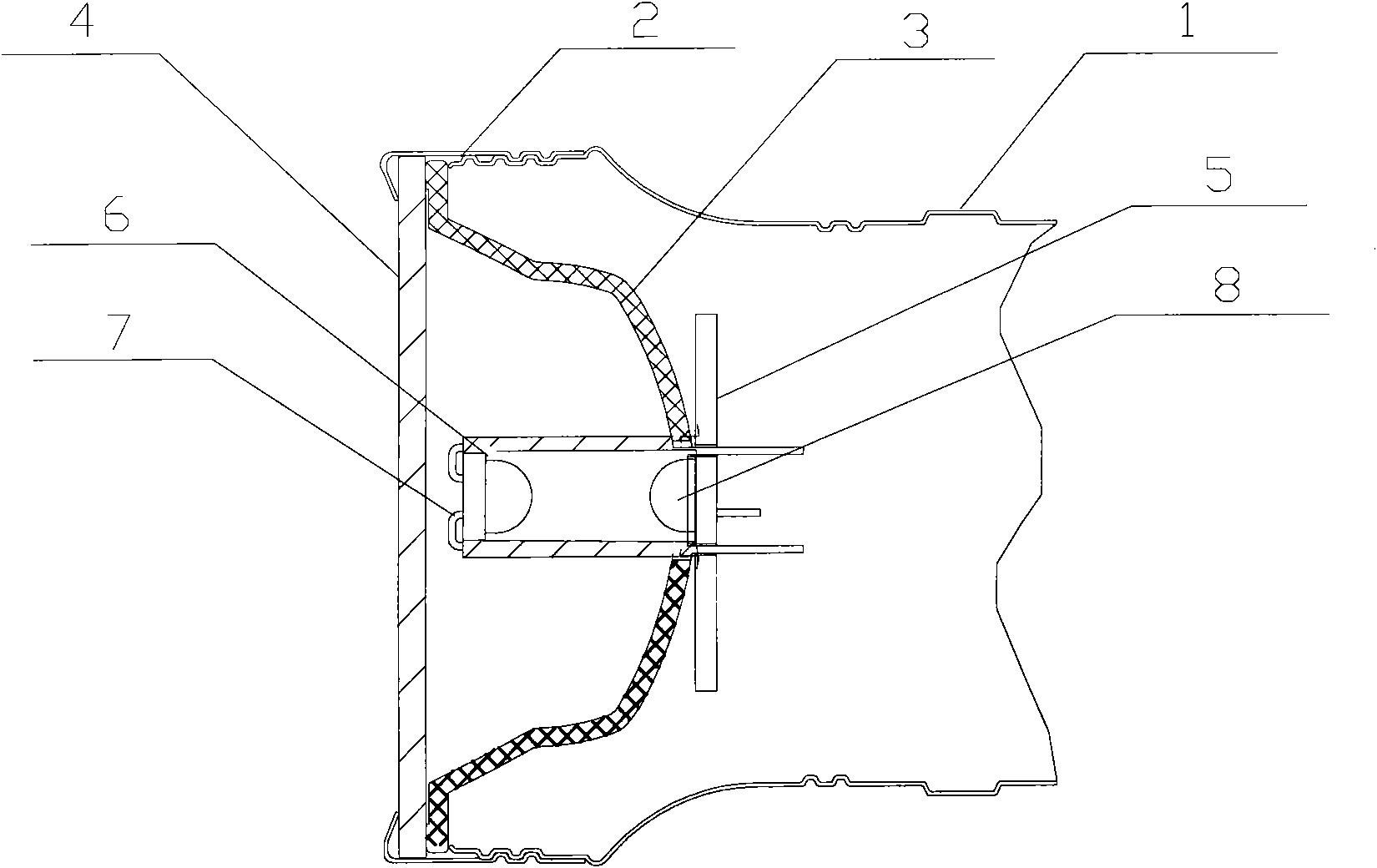

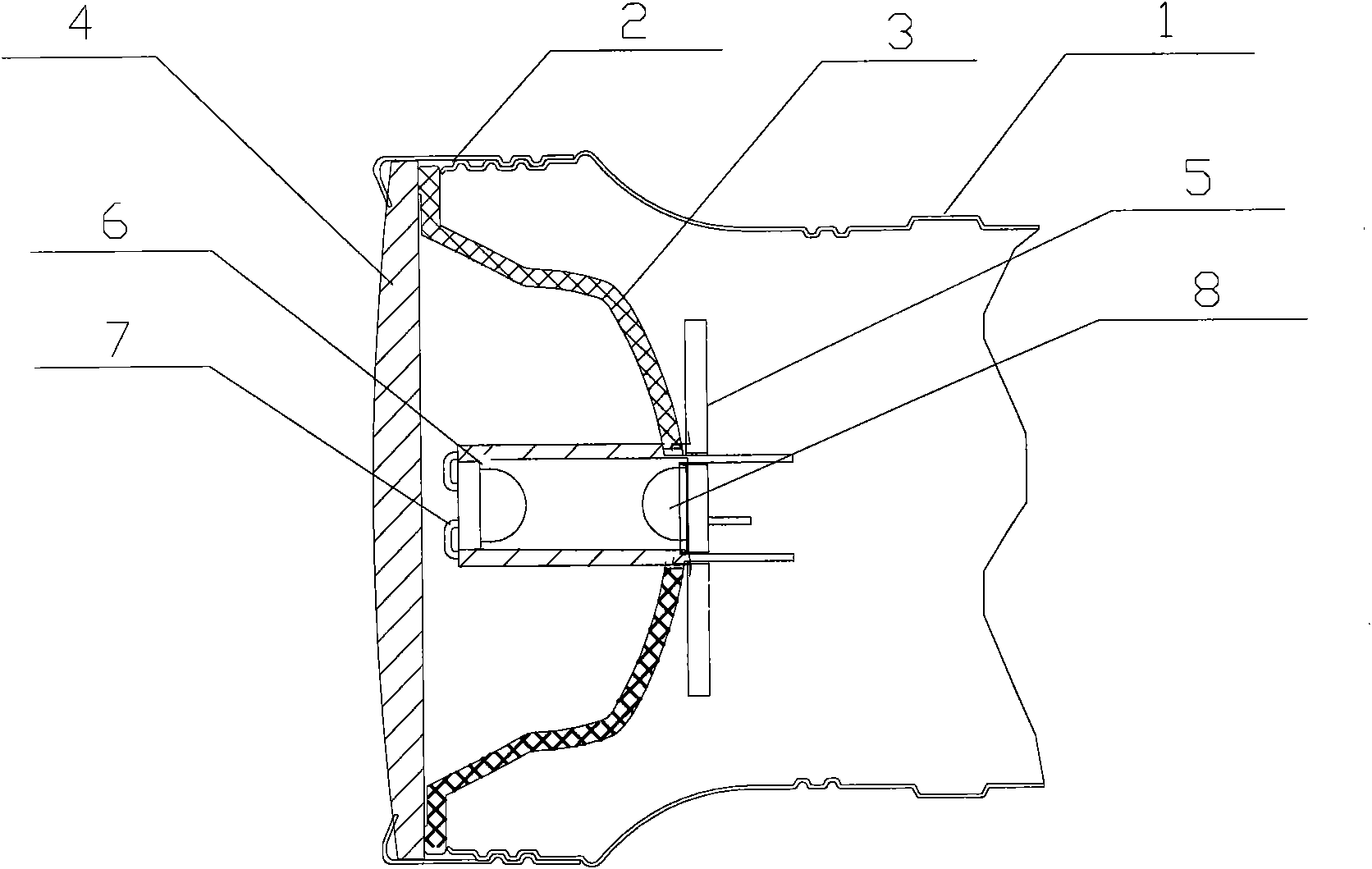

[0014] A hedging type LED light collection device, comprising a housing 1, a lamp cap 2, the lamp cap 2 is clamped or sleeved on the upper opening of the housing 1, the lower opening of the housing 1 is clamped or sleeved on the lamp body, and on the housing The inner side of the lower opening of 1 is clamped or socketed with a reflector 3, and a lens 4 is installed between the reflector 3 and the lamp cover 2; Install an LED7, the top direction of the LED7 is opposite to the opening direction of the reflector 3; the inside of the bottom of the reflector 3 and the corresponding position of the LED7 adopt a hedging type to install an LED8. The reflector 3 in the hedge type LED light collecting device is a double parabolic reflector, LED7 is installed on the focus of the inner parabola in the middle of the reflector 3, and LED8 is installed on the focus of the outer parabola on the reflector 3 periphery.

[0015] As another improvement of the present invention, the lens 4 in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com