Outside centering and clamping mechanism for disc parts

A technology of clamping mechanism and disc-type parts, applied in metal processing mechanical parts, clamping, positioning devices, etc., can solve the problems of large clamping force, troublesome operation, poor reliability, etc., and achieve easy operation and eliminate positioning. Clearance, the effect of improving machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

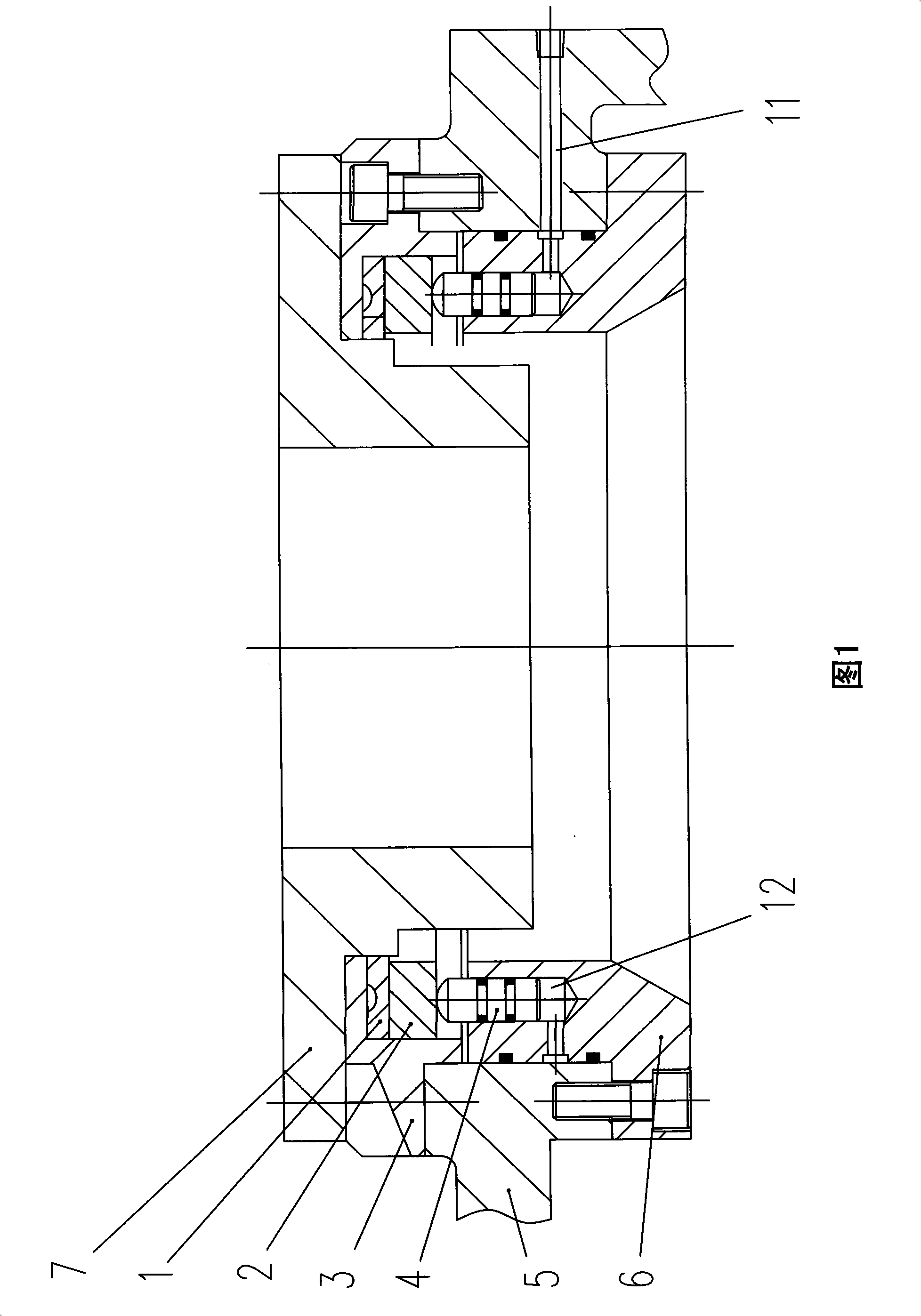

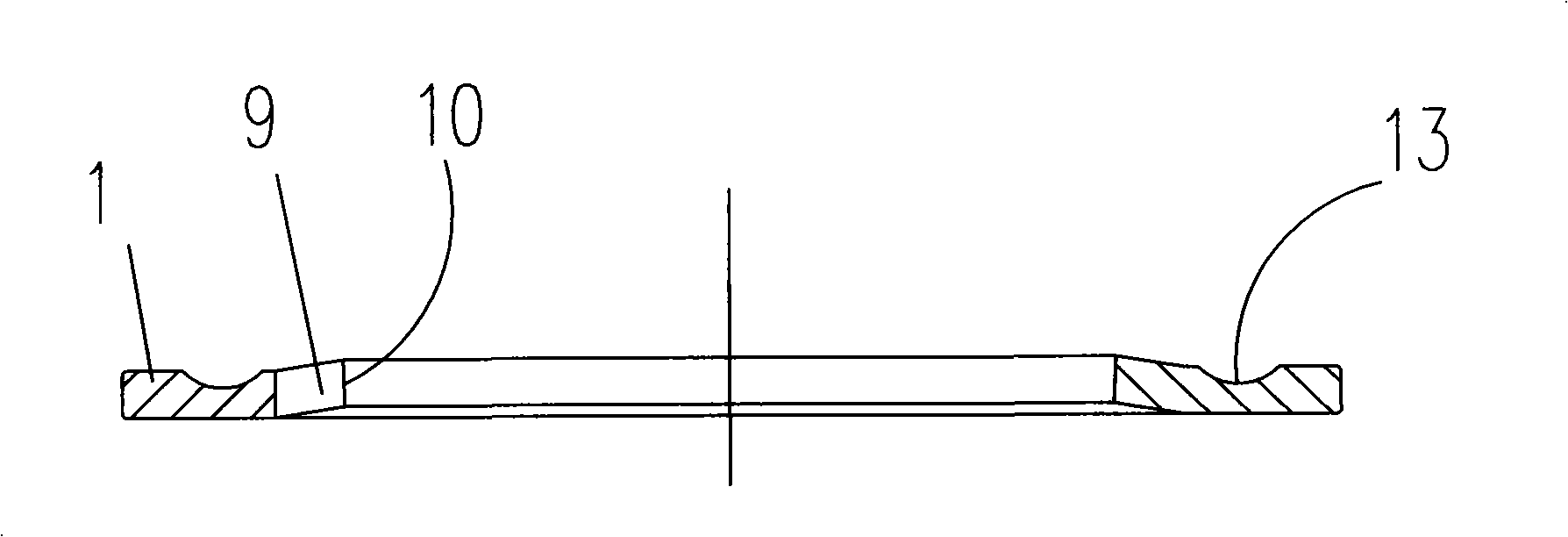

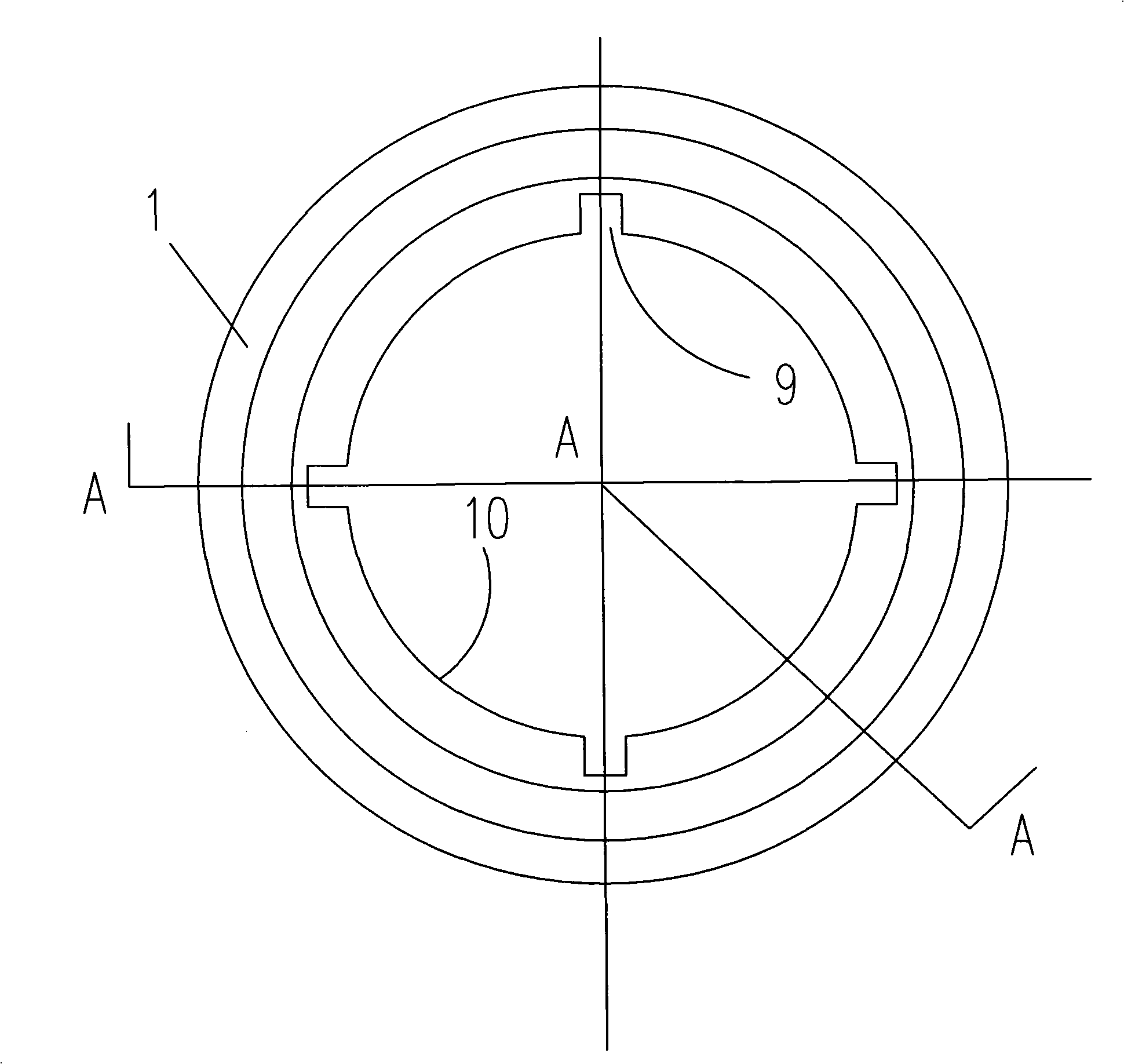

[0011] As shown in Figure 1: 5 is the clamp body, a plunger body 6 is arranged at the inner hole of the clamp body, and the plunger body 6 and the clamp body 5 are fixedly connected by bolts. A positioning disc 3 is fixedly connected with the clamp body 5 by bolts. A pressure plate 2 is installed inside the positioning plate 3 , and a radial elastic washer 1 is arranged between the pressure plate 2 and the end plate at the upper end surface of the positioning plate 3 . On the plunger body 6, there are plunger cavities 12 evenly distributed on the axial circumference, and the hydraulic plunger 4 is arranged in the plunger cavity 12. The upper end of the hydraulic plunger 4 matches the bottom surface of the pressure plate 2, so that Lean against the bottom surface of platen 2. An oil hole 11 communicating with the plunger cavity 12 is processed on the plunger body 6 and the clamp body 5 . During installation, the oil hole 11 is connected with the hydraulic control device throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com