Semi-automatic double-pole umbrella fabric pressure cutting machine

A semi-automatic, press-cutting technology, applied in the direction of mechanical equipment, transmission devices, gear transmission devices, etc., can solve the problem of low defective rate, achieve the effect of reducing fabric waste, reducing the probability of scrapped pieces, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

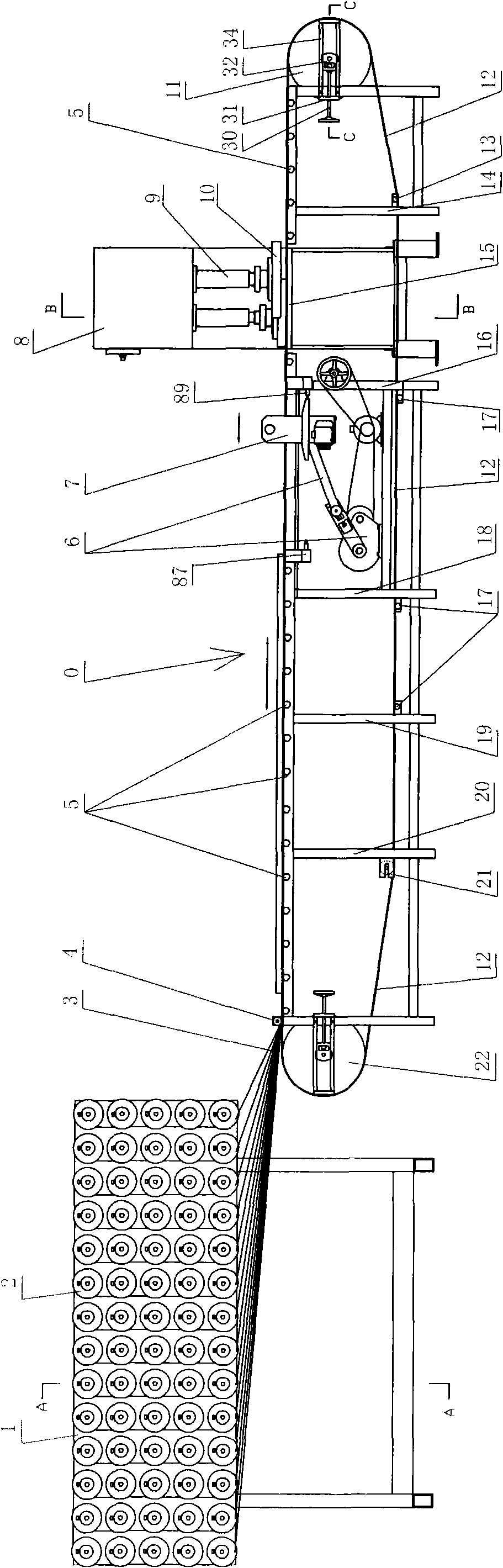

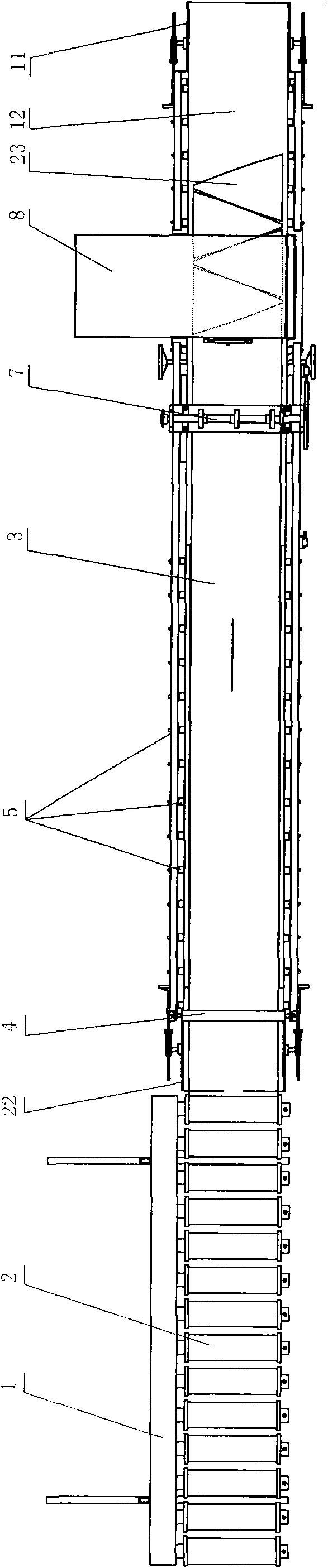

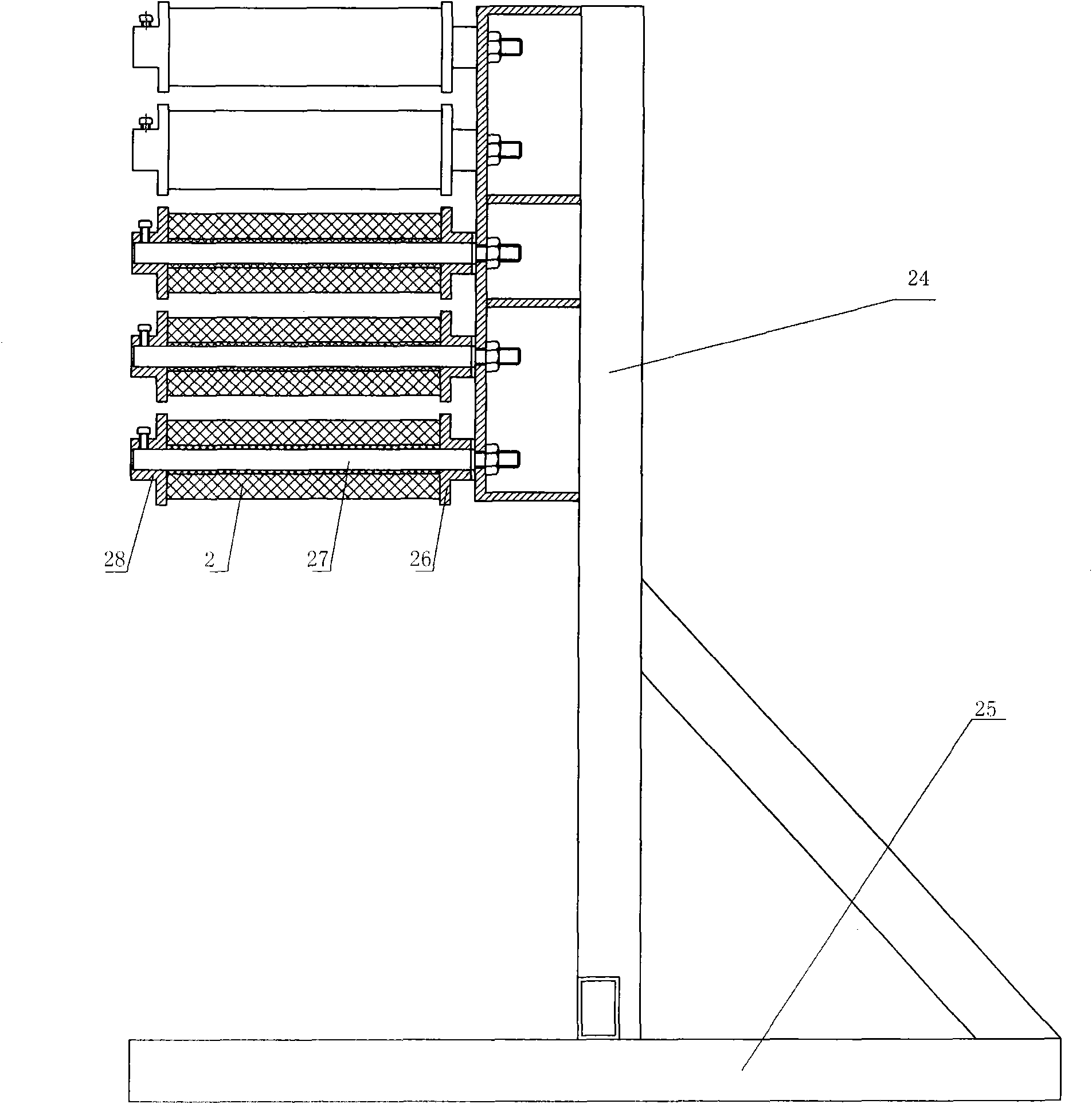

[0035] refer to figure 1 , figure 2 , Umbrella surface press-cutting machine of the present invention mainly comprises: fabric frame 1, frame 0, compression feeding mechanism, stamping mechanism 8. The fabric rack 1 is positioned directly behind the frame 0, on which 70 rolls of fabric rolls 2 can be loaded. A feed roller 11, 22 is respectively installed at the head and tail ends of the frame 0, and a conveyor belt 12 is closed after winding around the head and tail two feed rollers 12, 22 respectively. 21 parallel supporting rollers 5 are arranged successively on the top beam of the frame 0 to hold up the conveyor belt 12 and keep it horizontal. The middle and lower parts of the second group of columns 14 and the sixth group of columns 20 of the frame 0 are respectively provided with a tension roller 13, 21, and, in the third, fourth and fifth groups of columns 16, 18, 19 A lower-pass belt idler 17 is respectively established at the middle and lower part to prevent the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com