Preparation capable of improving intelligence, height, athletic ability and immunity and preparation method

A technology for exercise ability and immunity, applied in medical preparations containing active ingredients, pharmaceutical formulations, non-active ingredients of polymer compounds, etc., can solve the problems of high competition pressure, reduced body immunity, slow mutual compensation of zinc, etc. Achieve the effect of improving growth and development, improving intelligence and vision, and promoting protein metabolism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

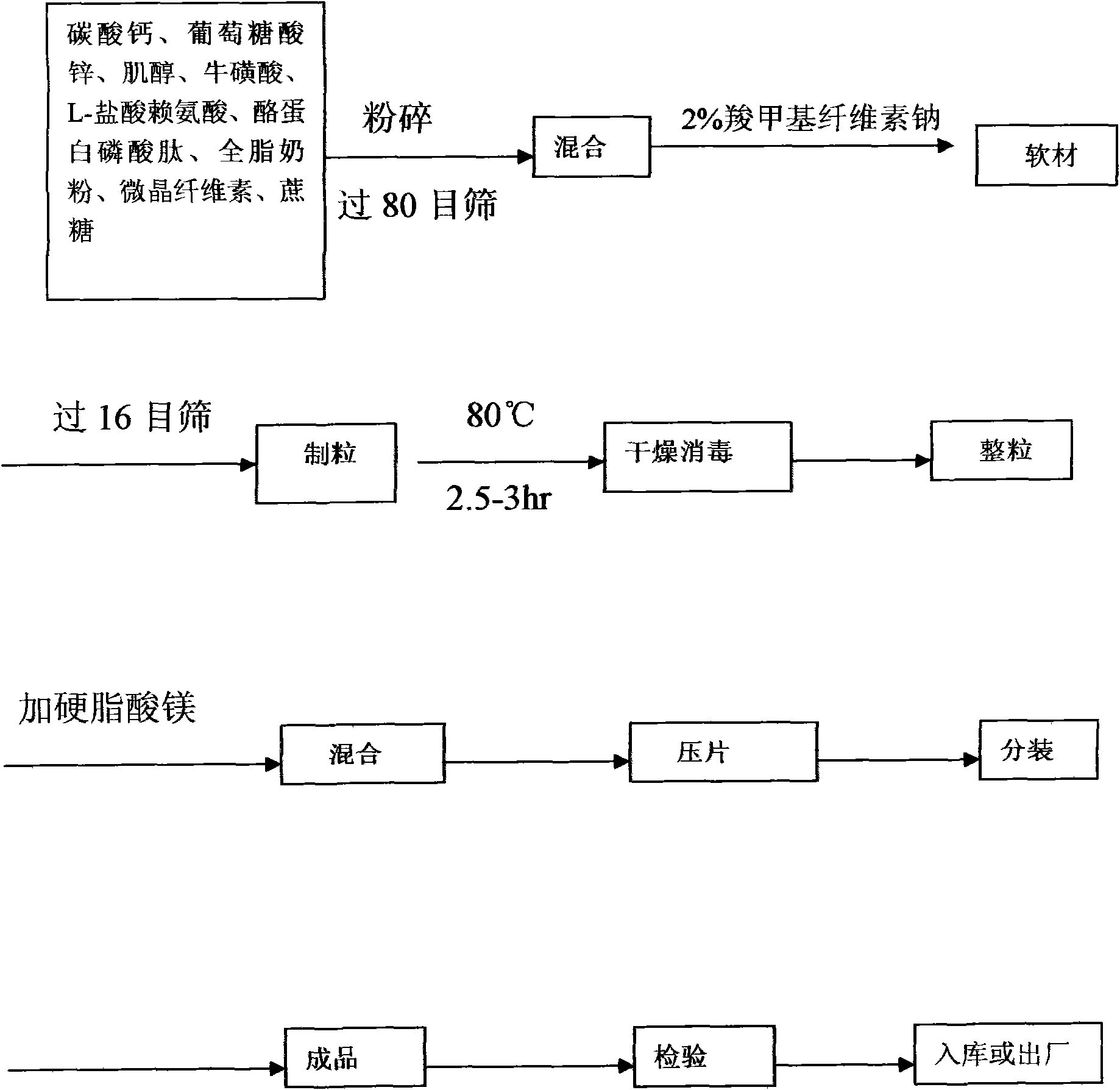

[0057] according to figure 1 Shown, a kind of preparation method of the preparation that can improve intellectual height motor ability immunity,

[0058] The steps are as follows:

[0059] ①. Weigh 16.55kg of calcium carbonate, 1.5kg of zinc gluconate, 0.5kg of inositol, 8kg of taurine, 18kg of L-lysine hydrochloride, 10kg of microcrystalline cellulose, 2.5kg of casein phosphopeptide, whole fat Milk powder 12kg, sucrose 27kg, crushed through 80-mesh sieve respectively;

[0060] ②. In a 100,000-level clean environment, mix the above-mentioned raw materials that have passed through a 80-mesh sieve in a V-type mixer. The mixer speed is 150 rpm for 6 minutes;

[0061] ③. In a 100,000-class clean environment, weigh 3.5 kg of sodium carboxymethyl cellulose, dissolve it in purified water to prepare a 2% sodium carboxymethyl cellulose solution, and mix the 2% carboxymethyl Add the sodium cellulose solution to the uniformly mixed powder in step ②, and mix evenly with a tank mixer to...

Embodiment 2

[0069] according to figure 1 Shown, a kind of preparation method of the preparation that can improve intellectual height motor ability immunity, its steps are as follows:

[0070] ①. Weigh 22.45kg of calcium carbonate, 0.5kg of zinc gluconate, 1.5kg of inositol, 3kg of taurine, 22kg of L-lysine hydrochloride, 6kg of microcrystalline cellulose, 3.5kg of casein phosphopeptide, whole fat 8kg of milk powder and 30kg of sucrose were crushed and passed through an 80-mesh sieve;

[0071] ②. In a 100,000-level clean environment, mix the above-mentioned raw materials that have passed through a 80-mesh sieve in a V-type mixer. The mixer speed is 150 rpm for 6 minutes;

[0072] ③. In a 100,000-level clean environment, weigh 2.5 kg of sodium carboxymethyl cellulose, dissolve it in pure water to prepare a 2% sodium carboxymethyl cellulose solution, and mix the 2% carboxymethyl Add the sodium cellulose solution to the uniformly mixed powder in step ②, and mix evenly with a tank mixer to m...

Embodiment 3

[0080] according to figure 1 Shown, a kind of preparation method of the preparation that can improve intellectual height motor ability immunity, its steps are as follows:

[0081] ①. Weigh 18.5kg of calcium carbonate, 1kg of zinc gluconate, 1kg of inositol, 5.5kg of taurine, 20kg of L-lysine hydrochloride, 8kg of microcrystalline cellulose, 3kg of casein phosphopeptide, and 10kg of whole milk powder , 29.5kg of sucrose, respectively crushed through an 80-mesh sieve;

[0082] ②. In a 100,000-level clean environment, mix the above-mentioned raw materials that have passed through a 80-mesh sieve in a V-type mixer. The mixer speed is 150 rpm for 6 minutes;

[0083] ③. In a 100,000-level clean environment, weigh 3kg of sodium carboxymethyl cellulose, dissolve it in pure water to prepare a 2% sodium carboxymethyl cellulose solution, and mix the 2% carboxymethyl cellulose Add plain sodium solution to the uniformly mixed powder in step ②, and mix evenly with a tank mixer to make a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com