Error detecting system of minitype high accuracy three coordinate measuring machine

A three-coordinate measuring machine, high-precision technology, used in measuring devices, instruments, optical devices, etc. It can improve the verification efficiency, easy to understand and grasp, and the measurement space is small.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

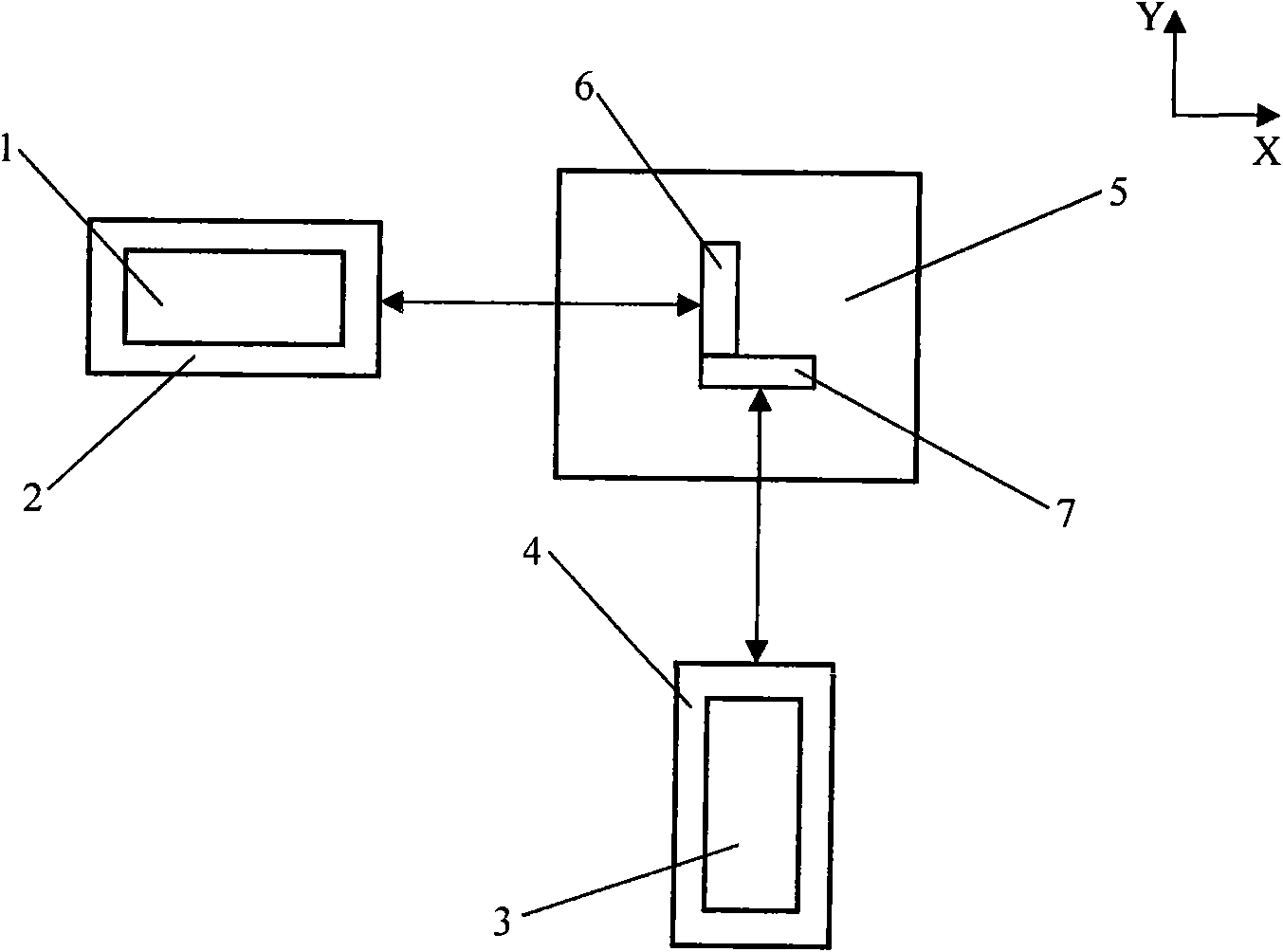

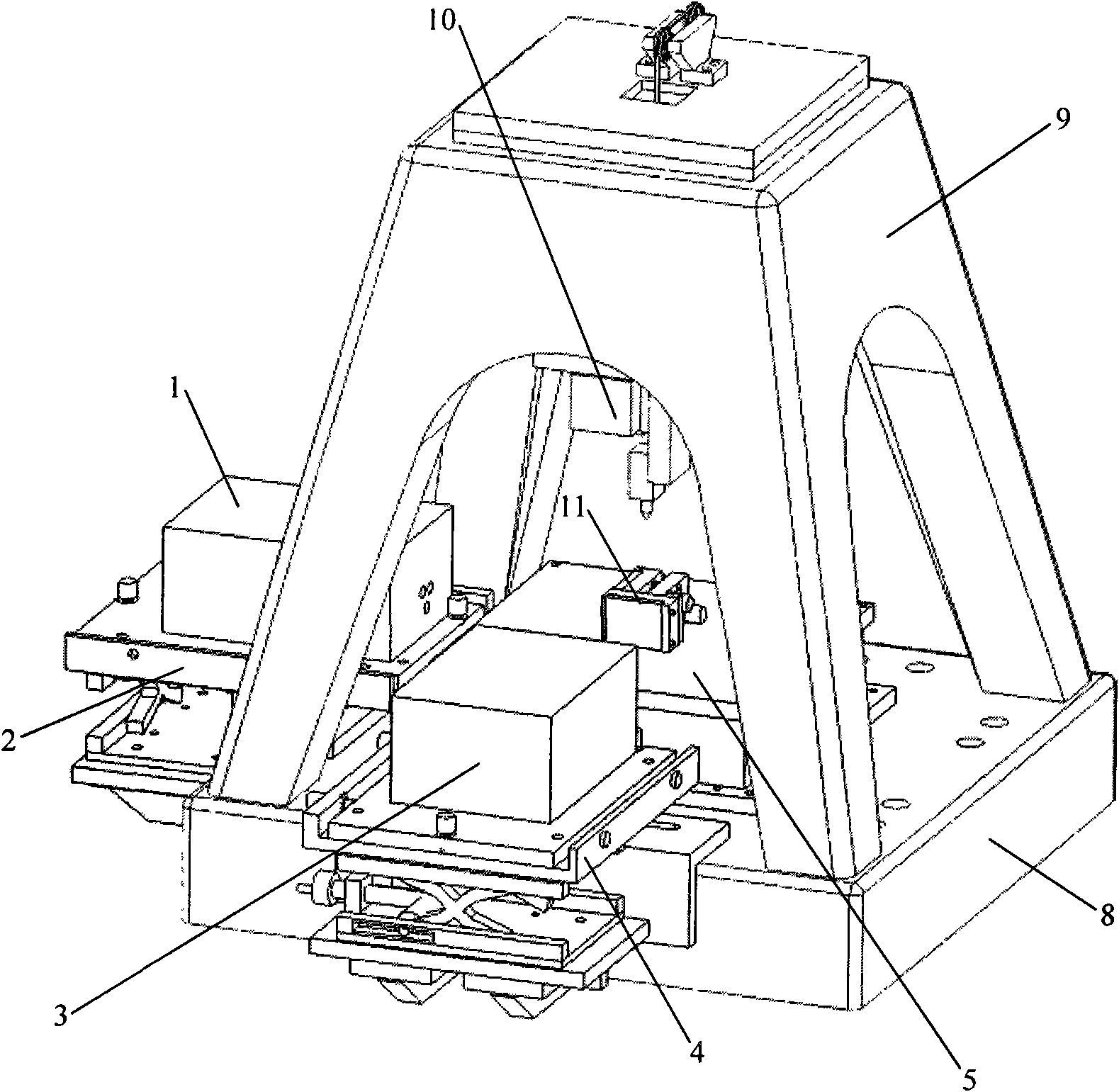

[0025] Such as figure 1 , figure 2 and Figure 5 As shown, the X / Y axis target mirror 11 has a longitudinal side plane reflector 6 whose mirror surface is parallel to the Y axis, a horizontal side plane reflector 7 whose mirror surface is parallel to the X axis, and is used to support the longitudinal side plane reflector 6 and the X / Y axial target mirror holder 19 of the horizontal plane mirror 7, the X / Y axial target mirror holder 19 can be placed on the coplanar biaxial positioning platform 5 of the three-coordinate measuring machine;

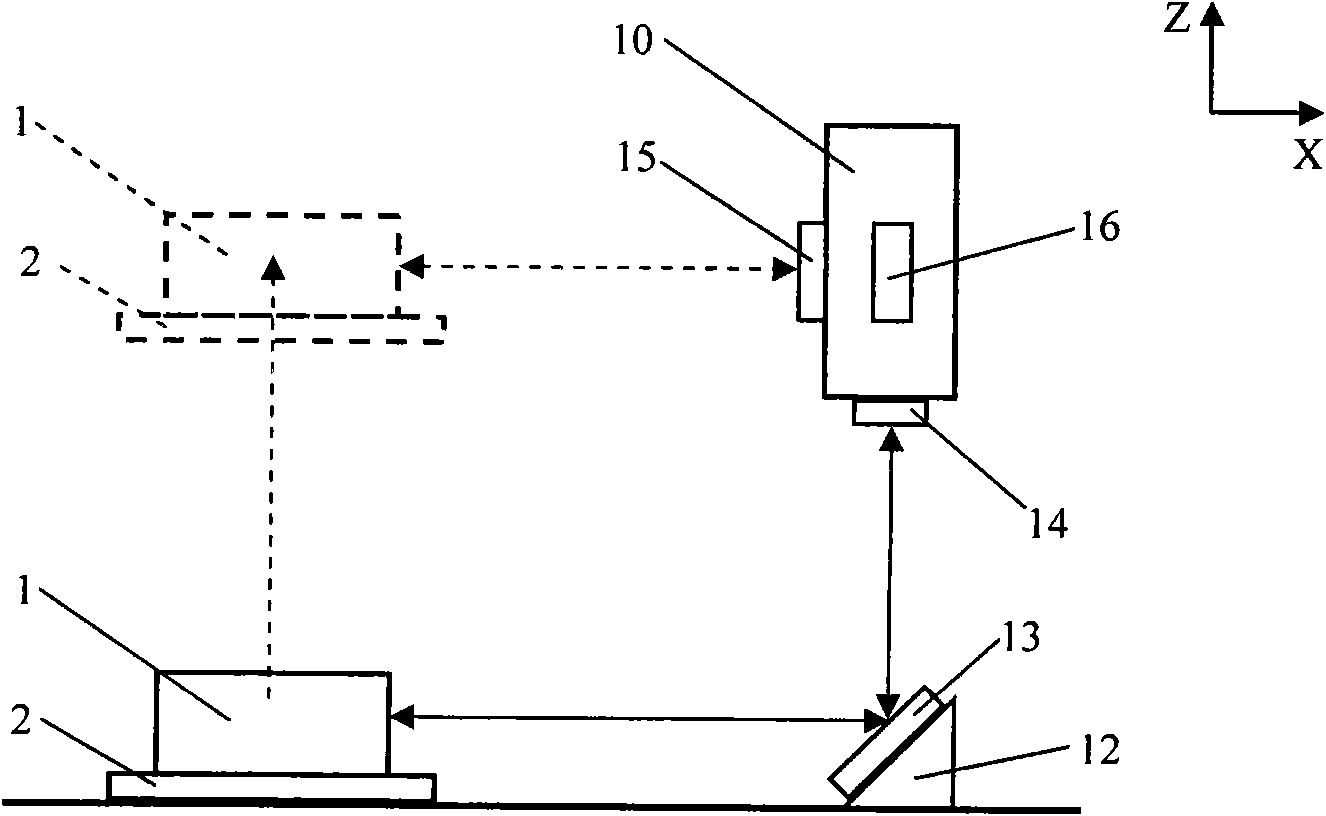

[0026] Such as image 3 , Figure 4 and Figure 7 As shown, the optical path turning target mirror 17 has an optical path turning mirror 13 with a mirror surface and a horizontal plane at an angle of 45° and an optical path turning target mirror holder 12 for supporting the optical path turning mirror 13, and the optical path turning target mirror holder 12 can be placed on three On the coplanar biaxial positioning platform 5 of the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com