Harmless recycling treatment process for urban sludge

A technology of urban sludge and recycling, applied in the field of environmental protection and governance, can solve the problems of landfill sludge occupying large agricultural land, large investment in bio-composting equipment, and high investment and maintenance costs, so as to prevent human contact and construction The effect of short cycle time and high drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

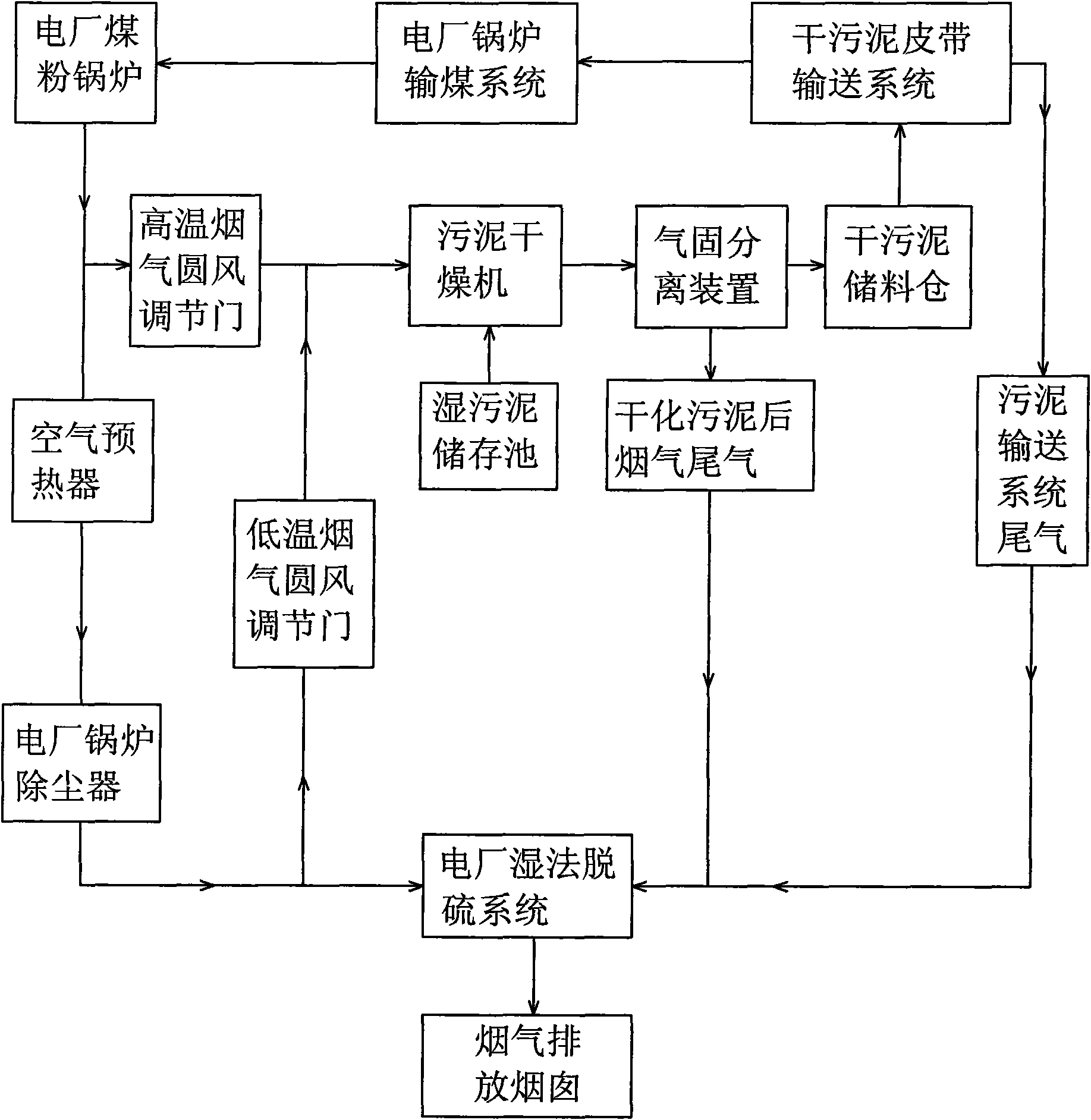

[0039] As shown in the figure of the present invention, the present invention can dry 4-5 t / h of municipal sludge. The drying medium of the urban sludge in the present invention is the flue gas of the coal-fired boiler of the power plant, and a part of the flue gas is extracted from the front part of the Junker type rotary air preheater of the pulverized coal boiler of the power plant with an evaporation capacity of 480t / h for 310~ 350℃ flue gas 36000~40000Nm 3 / h, this part of the flue gas is regulated and transported by the DN1100mm (diameter) pipe through the high-temperature flue gas round air regulating door; the other part is extracted from the rear of the power plant boiler dust collector at 110-130°C flue gas 96000-102000Nm 3 / h, this part of the flue gas is transported by the DN1000mm (diameter) pipeline and regulated by the low-temperature flue gas circular air regulating door; the two-way flue gas is mixed into the DN1100mm (diameter) pipeline, and the temperature i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com