Preparation method of high-purity low-radioactivity spherical silicon micropowder

A technology of spherical silicon micropowder and low radioactivity, which is applied in the direction of silicon oxide, silicon dioxide, etc., can solve the problems of inability to prepare low-radioactive spherical silicon micropowder, unsatisfactory spherical silicon micropowder, and high cost of the method, and achieve low content of radioactive elements and low cost. Low cost and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

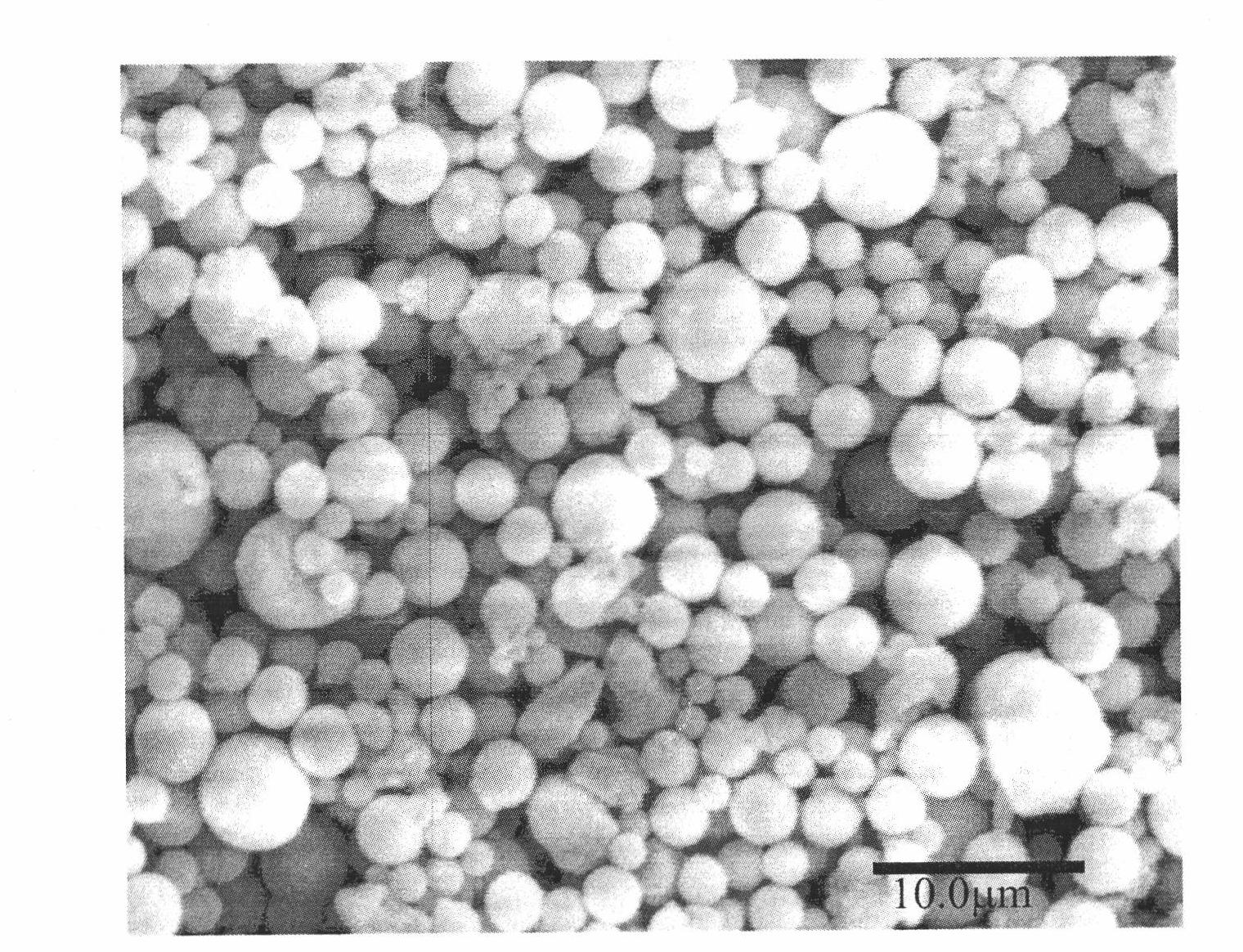

[0030] With the content of radioactive element U≤1×10 -9 The silicon source of g / g is raw material preparation silica sol, and the purity of silica sol is 99.98% (wherein any kind of impurity ion content all≤5×10 -6 g / g), the solid content of the silica sol after concentration is 41%, and the particle size is 4.5 μm through air-flow spray granulation, roasting at 800 °C for 1 h, liquefied petroleum gas (LPG) is the fuel gas, oxygen is the combustion gas, and oxygen is the delivery gas. Powder carrier gas, adjust the pressure and flow rate of oxygen and LPG, then ignite, preheat the spheroidizing furnace for 50 minutes (generally, the preheating temperature should not be lower than 1500°C), and the powder feeding rate is 300g / min. Analysis of SiO in products by gravimetric method 2 content, ICP-MS detection of radioactive element content, laser particle size analyzer to test particle size and SEM of the product (the SEM image of the product is shown in figure 1 Shown) and XRD...

Embodiment 2

[0032] With the content of radioactive element U≤1×10 -9 The silicon source of g / g is raw material preparation silica sol, and the purity of silica sol is 99.98% (wherein any kind of impurity ion content all≤5×10 -6 g / g), the solid content of the silica sol is 50% after concentration, the particle size after granulation is 15.4 μm, roasted at 800°C for 1h, acetylene is the gas, oxygen is the combustion gas, and the oxygen is the carrier gas for powder delivery. , the pressure and flow rate of acetylene and then ignite, the spheroidizing furnace is preheated for 50 minutes, and the powder feeding rate is 100g / min. Analyzed by the same method as Example 1, prepared SiO 2 The content is 99.96%, and the radioactive element U content is 0.05×10 -9 Spherical silica powder with g / g, median particle size of 9.6μm, spheroidization rate of 92%, and amorphous rate of 100%.

Embodiment 3

[0034] With the content of radioactive element U≤1×10 -9 The silicon source of g / g is raw material preparation silica sol, and the purity of silica sol is 99.99% (wherein any impurity ion content all≤5×10 -6 g / g), the solid content of the silica sol after concentration is 60%, the particle size after granulation is 40.6 μm, roasting 40min at 1100°C, natural gas is the fuel gas, oxygen is the combustion gas, and oxygen is the carrier gas for powder delivery. After the pressure and flow of natural gas are ignited, the spheroidizing furnace is preheated for 50 minutes, and the powder feeding rate is 50 g / min. Analyzed by the same method as Example 1, prepared SiO 2 The content is 99.96%, and the radioactive element U content is 0.01×10 -9 Spherical silica powder with g / g, medium particle size of 22.6μm, spheroidization rate of 99%, and amorphous rate of 99%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com