System and method for automatic detection

An automatic detection and test board technology, applied in neural learning methods, measuring electricity, measuring devices, etc., can solve problems such as affecting test results, speeding up test time, and rising costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

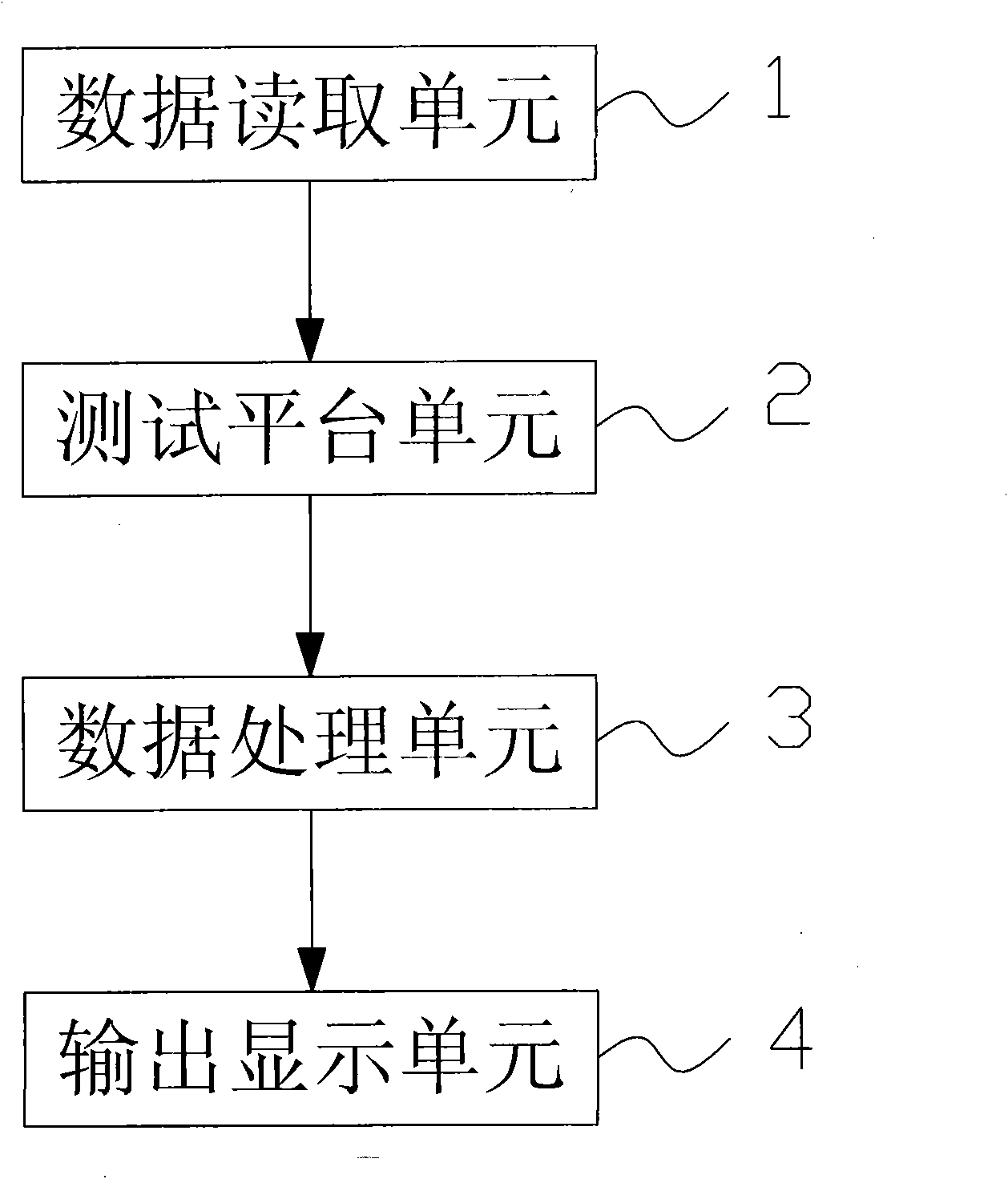

[0037] see figure 1 As shown, it is a block diagram of the automatic detection system of the present invention.

[0038] The automatic detection system of the present invention comprises:

[0039] A data reading unit 1, which is used to capture the image file of the light-emitting diode state display lights on the board to be tested, and the data reading unit 1 can be one of a camera, a video camera, and a video camera;

[0040] A test platform unit 2, which is connected with the above-mentioned data reading unit 1, and the test platform unit 2 is used for fixing, connecting and testing the board to be tested;

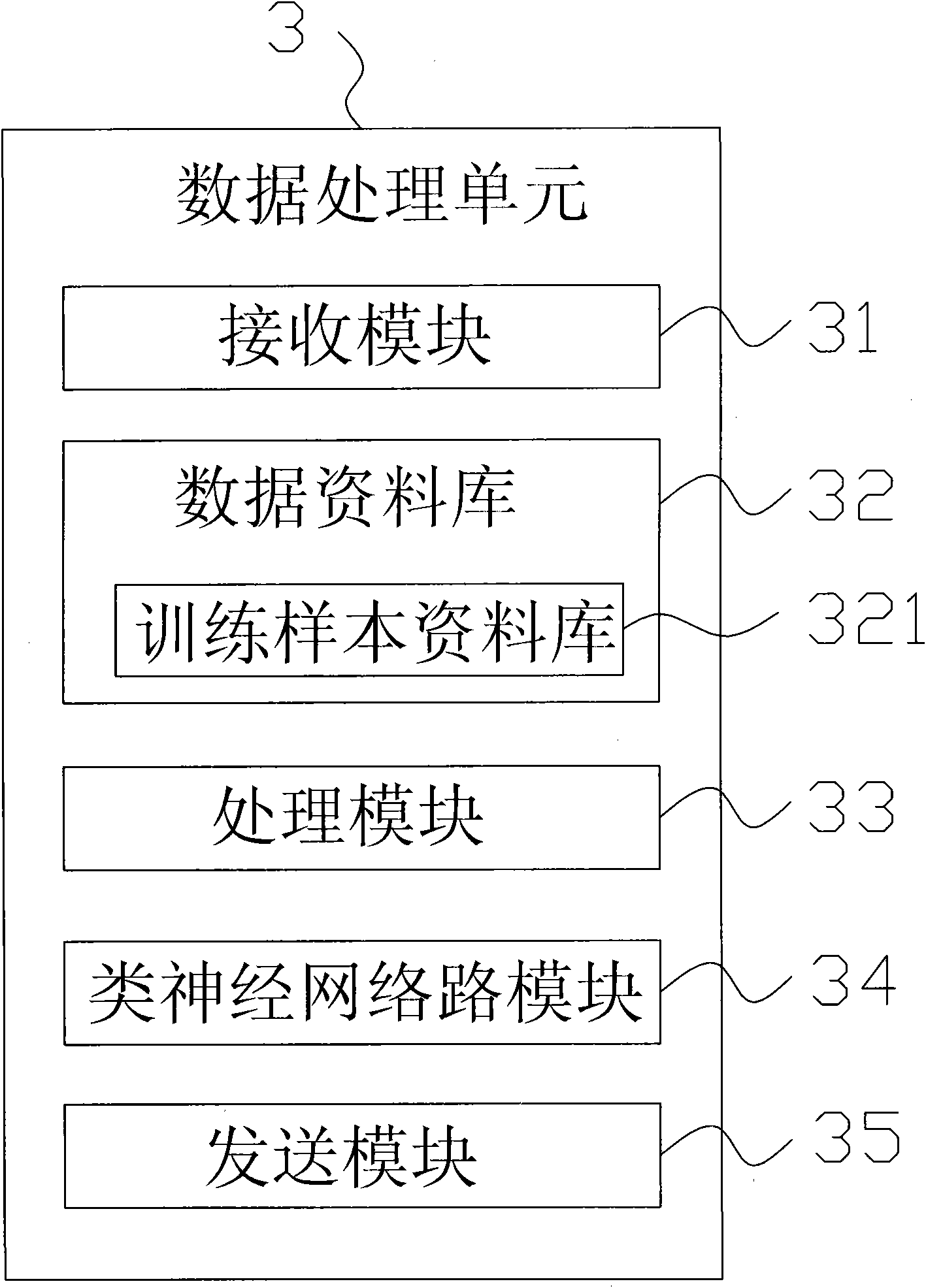

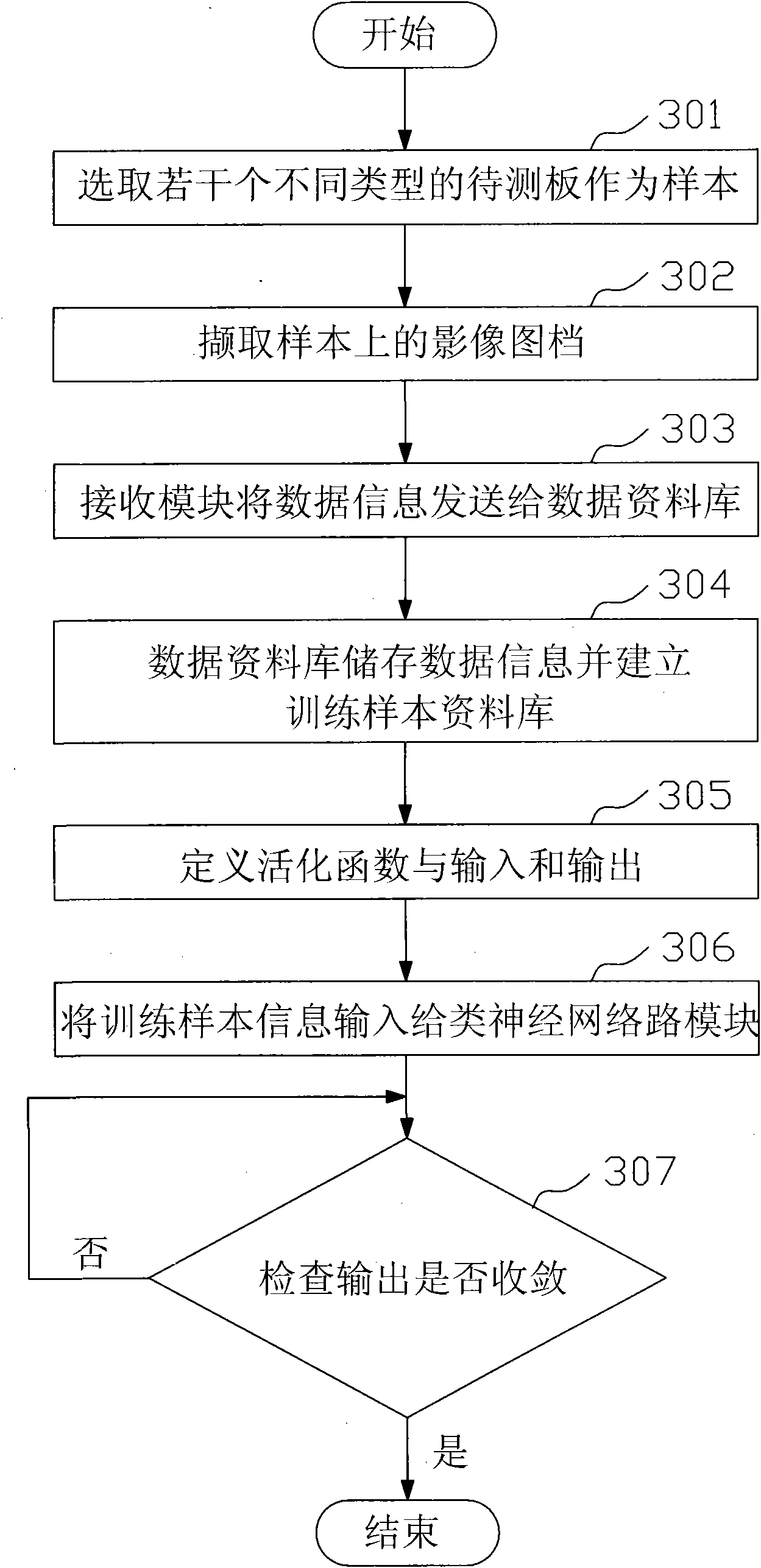

[0041] A data processing unit 3, which is connected with the above-mentioned test platform unit 2, and is connected with the above-mentioned data reading unit 1 through the test platform unit 2 and performs data transmission, and stores the data information of the above-mentioned image file at the same time, the data processing unit 3 is the processor of the computer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com