A Seawater Circulation System for Corrosion Fatigue Tests on Metal Materials

A technology of corrosion fatigue and metal materials, applied in the fields of analysis of materials, weather resistance/light resistance/corrosion resistance, measuring devices, etc., can solve problems such as the successful design example of seawater circulation system that has not yet been seen, and the lack of detailed textual descriptions of sealing methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

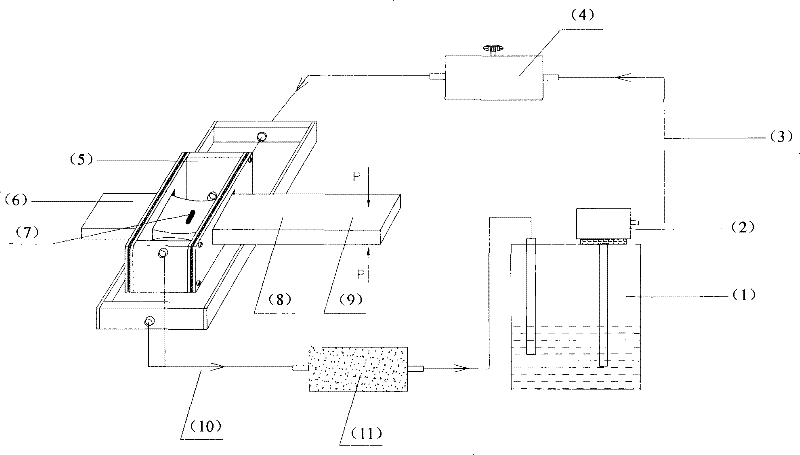

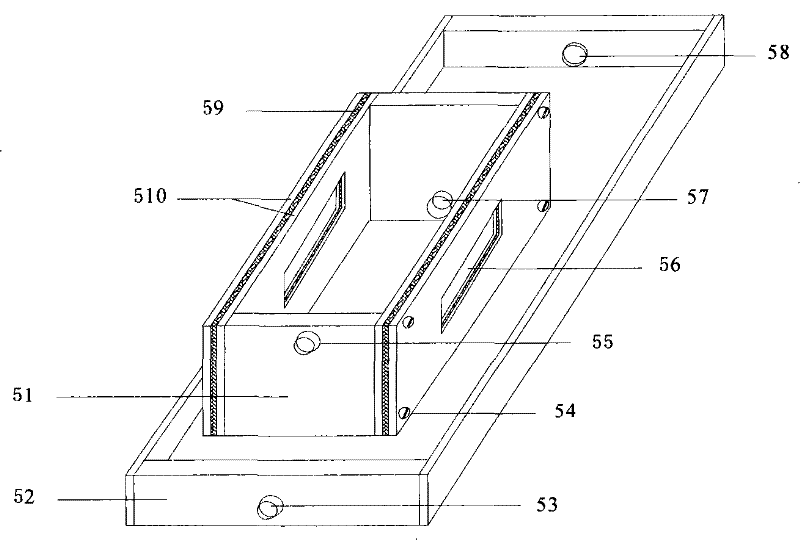

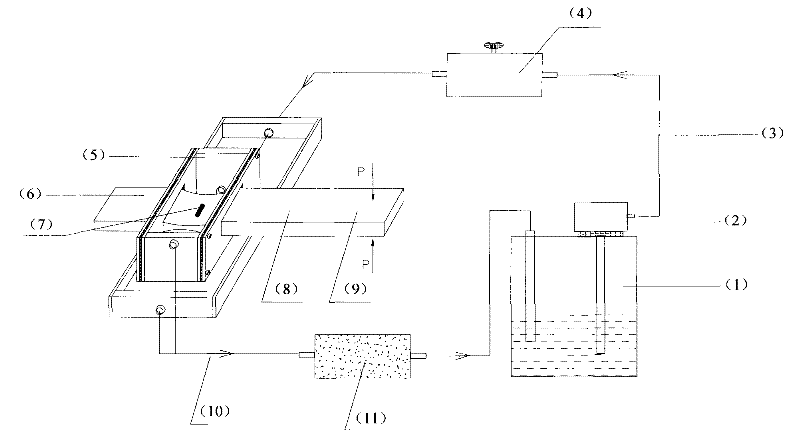

[0017] combine figure 1 , provide the power source micro-pump to drive the circulation of seawater, the water flow control valve to control the water intake, the double-layer anti-leakage corrosion device to ensure that the crack of the sample is always in the seawater and easy to observe clearly, and the filter to ensure that the seawater is always clean Each link is relatively independent and connected with each other, forming a seawater circulation system that ensures that the cracks in the working part of the sample are always in the simulated flow of natural seawater.

[0018] In the past, when conducting axial corrosion fatigue tests, an isolated corrosion device was often designed. As the test progressed, the crack length of the sample could not be clearly observed due to the continuous entry of corrosion products into the corrosive solution, even if certain measures were taken to circulate the corrosive solution. When it flows, it is often difficult to maintain a certa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com