Pipe expander for spherical corrugated pipe

A tube expander and corrugated tube technology, which is applied in the field of spherical tube expanders, can solve problems such as wear resistance and mechanical strength that cannot be well adapted, and tube expansion components fall off, so as to achieve better trimming effect and eliminate easy fall off , The effect of simplifying the structure of the bearing system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with embodiment, further illustrate the present invention.

[0025] The implementation steps are as follows:

[0026] (1) Run the expandable bellows in the 215.9mm wellbore, and the shape of the expandable bellows is "8";

[0027] (2) Put the copper ball into the seal, and pressurize about 20MPa through the cement truck or mud pump. At this time, the shape of the expandable corrugated pipe still has a certain ellipticity and the surface of the pipe is uneven;

[0028] (3) undercut, trip out, run into the spherical tube expander of the present invention, pressurize, open the pump, rotate and press down;

[0029] (4) Until the end face of the expandable bellows can ensure the smooth passage of the drilling tool, put out the expander.

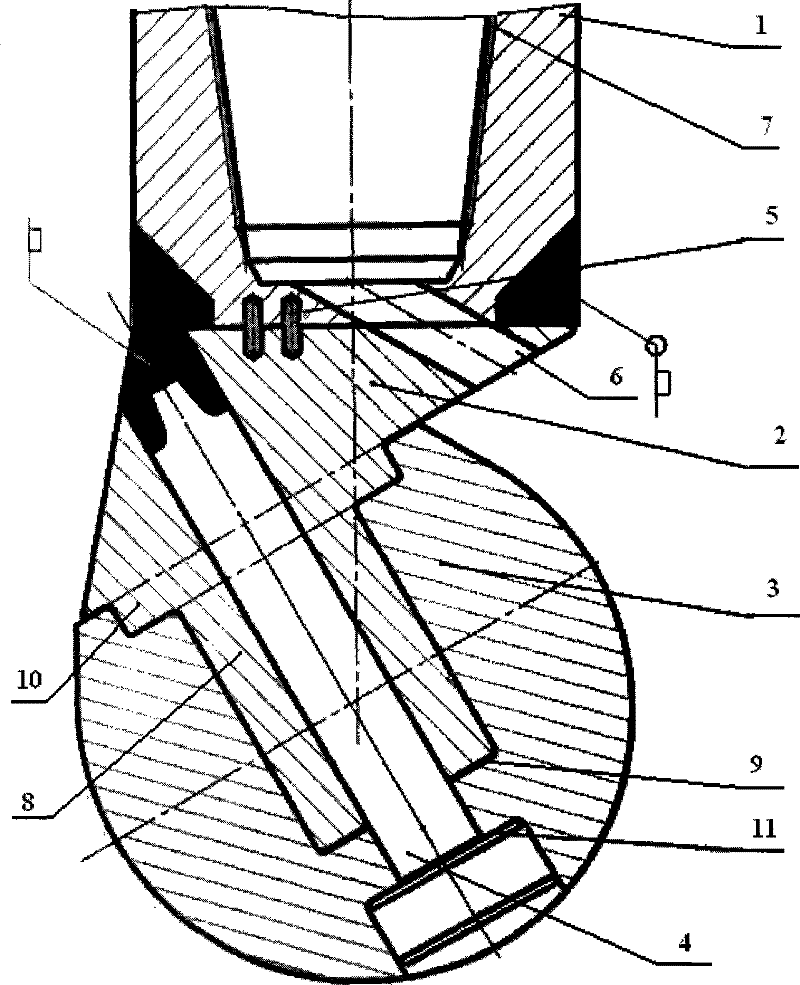

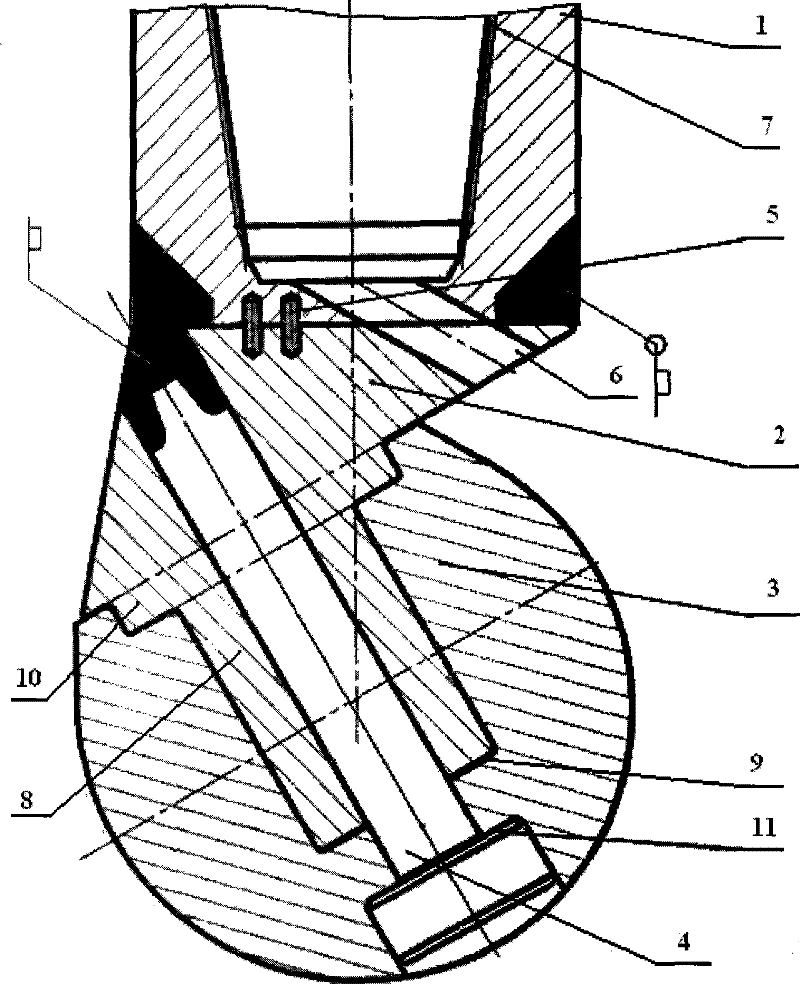

[0030] The spherical tube expander of the present invention described in the above steps is as figure 1 As shown, it includes a roller body 1, a roller shaft 2 and a tube expander sphere 3.

[0031] Wherein said ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com