Inserting pipe-type spinning nozzle

A technology of inserting tube type and spinneret, which is applied in the direction of rayon manufacturing, hollow filament manufacturing, fiber chemical characteristics, etc., can solve the problem of uneven wall thickness of hollow fiber membranes, unsatisfactory product quality, affecting the stability of hollow membrane quality and Improvement and other issues, to achieve the effect of uniform wall thickness distribution and product quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Further describe the present invention below in conjunction with embodiment and accompanying drawing thereof. The specific embodiments are only for further clearly illustrating the structure of the concentricity adjuster of the spinneret of the present invention, and do not constitute limitations on the claims of the present invention.

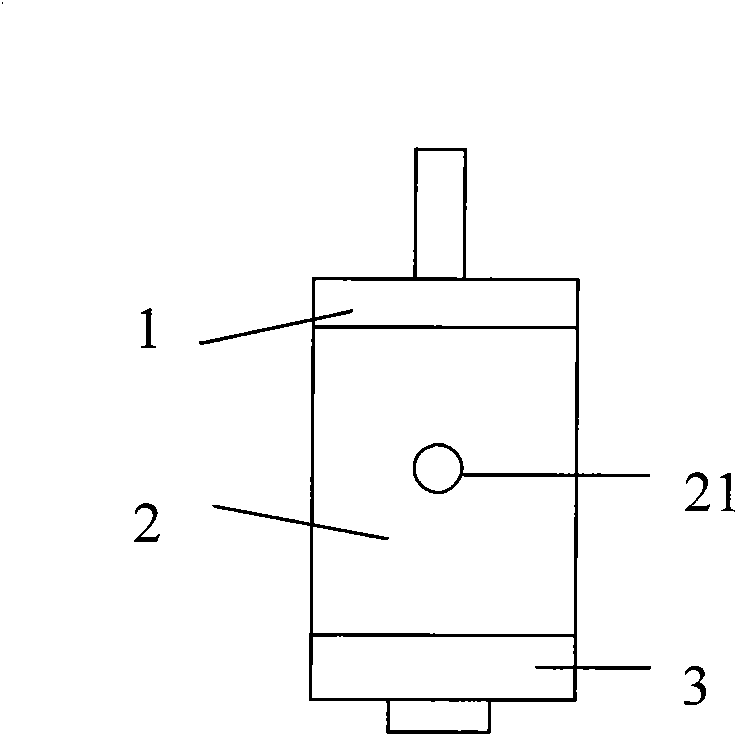

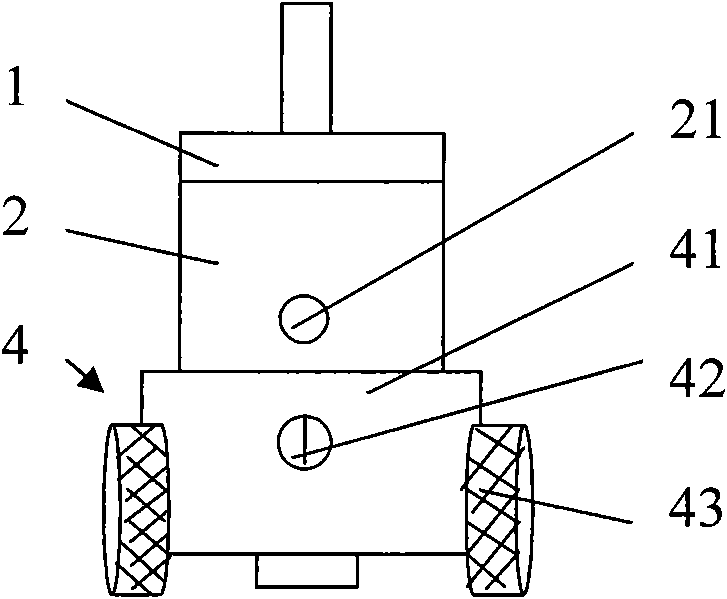

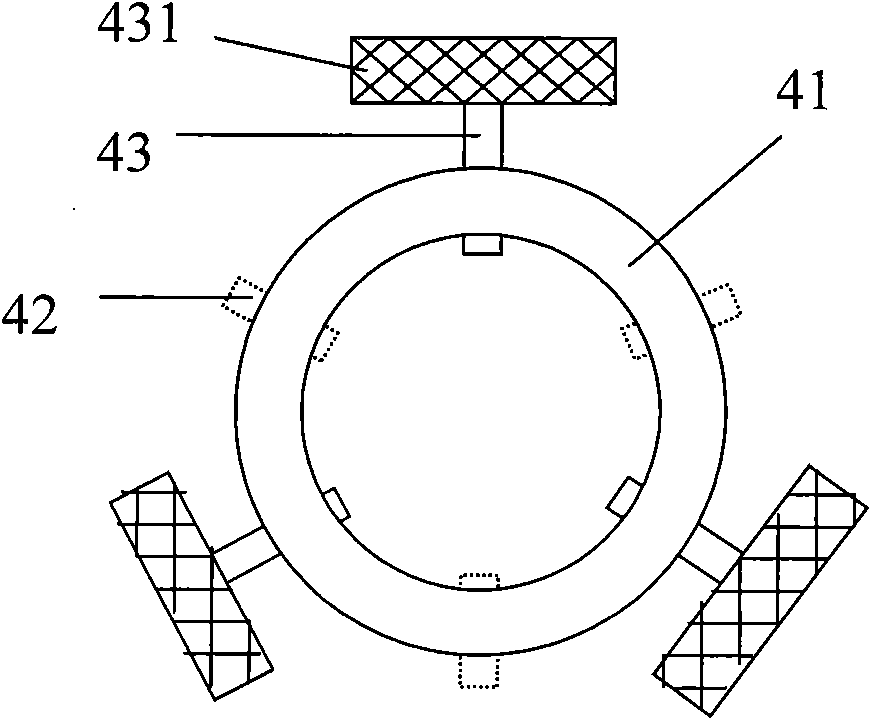

[0013] Insert tube type spinneret (hereinafter referred to as spinneret for short, refer to Figure 1-4 ), comprising an insertion tube 1, a spinneret housing 2 and a spinneret plate 3, characterized in that the spinneret is equipped with a concentricity regulator 4, and the concentricity regulator 4 is connected with the spinneret housing 2 Cooperating casing 41, top screw 42 and adjusting screw 43 are formed; 3-4 fixed threaded holes 412 and 3-4 adjusting threads are evenly distributed on two mutually parallel cross-sections of the casing 41 hole 413; the top wire 42 and the adjusting screw 43 are fitted with the fixing screw hole 41...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com