Normal pressure water purifier adopting powder water treatment material and microporous ceramic

A technology of atmospheric water purifiers and microporous ceramics, applied in water/sewage treatment, adsorption water/sewage treatment, water/sludge/sewage treatment, etc., can solve secondary pollution of water purifiers, insufficient adsorption, Eliminate problems such as insufficient thoroughness, and achieve the effects of high effective utilization, safe drinking water, and good water taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

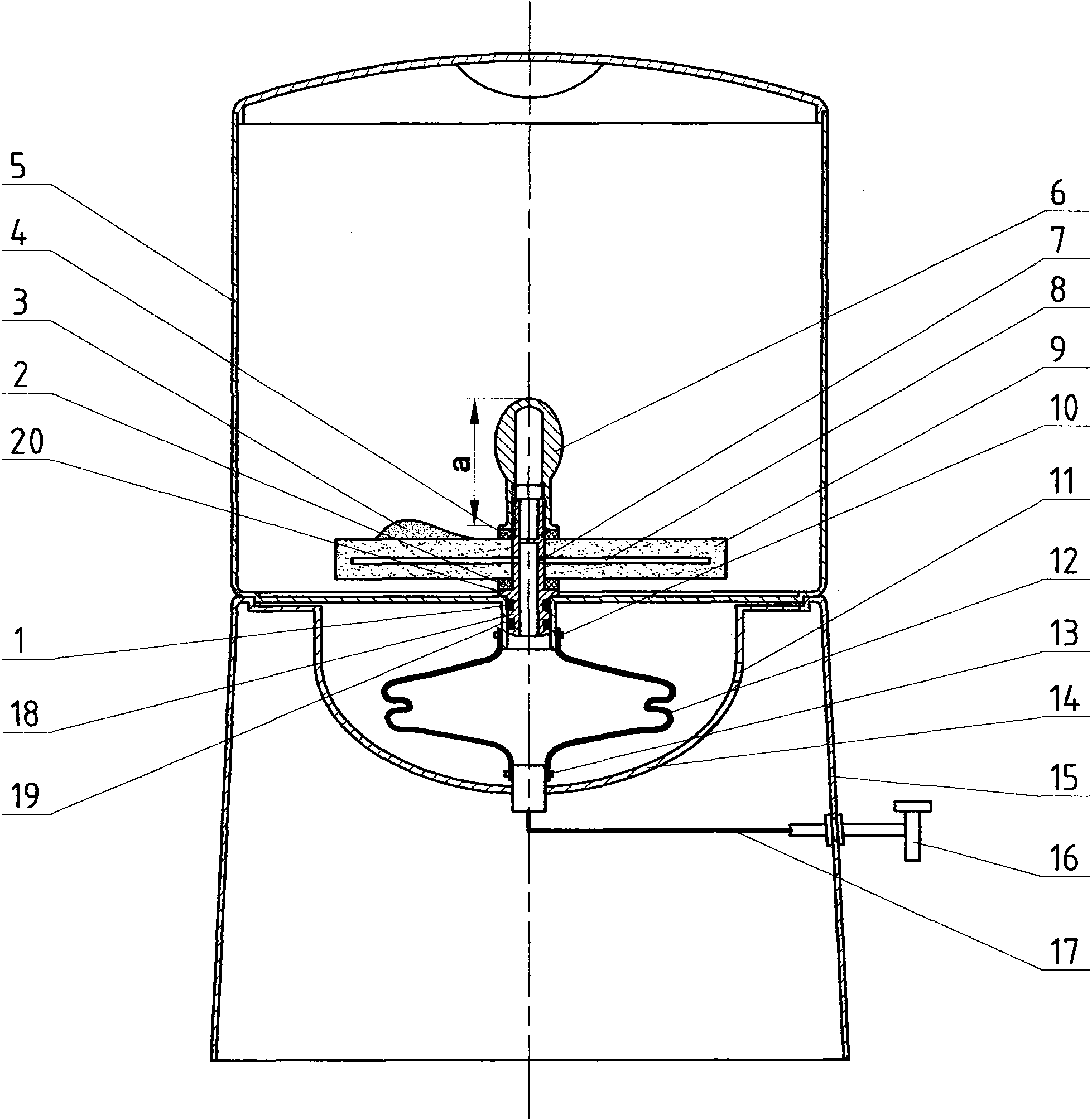

[0033] Example 1: Combination figure 1 As shown, this embodiment uses a powdered water treatment material and a microporous ceramic atmospheric water purifier, including the powdered water treatment material 3, the double-sided filter plate-shaped microporous ceramic 9, the raw water bucket 5 and the water storage bag 12. The bottom of the raw water bucket 5 is provided with a double-sided filter plate-shaped microporous ceramic 9; the thickness of the double-sided filter plate-shaped microporous ceramic 9 is provided with a water flow channel 8; the raw water bucket 5 is provided with a powdered water treatment material 3, powder The water treatment material 3 includes powdered activated carbon with a particle size of 60 mesh to 200 mesh; a protective shell 14 is provided under the original water bucket 5, and the protective shell 14 is provided with vent holes 11; a water storage bag 12 is arranged in the protective shell 14 to store water The water inlet of the bag 12 is in a s...

Embodiment 2

[0034] Embodiment 2: Combination figure 2 As shown, this embodiment uses a powdered water treatment material and a microporous ceramic atmospheric water purifier, including a powdered water treatment material, a double-sided filter plate-shaped microporous ceramic, a raw water bucket 25 and a water storage bag, and the raw water bucket 25 There is a double-sided filter plate-shaped microporous ceramic at the top of the bottom. The double-sided filter plate-shaped microporous ceramic forms a microporous ceramic component through the upper rectangular sealing ring, the upper joint, the lower rectangular sealing ring and the lower joint 21. The middle of the lower joint 21 The outer surface of the lower pipe body is provided with external threads, and the lower joint 21 is also provided with a circumferential rib 24; the bottom of the original water bucket 25 is provided with a groove capable of assembling an O-ring 23, and an O-ring is installed in the groove 23; The bottom surface...

Embodiment 3

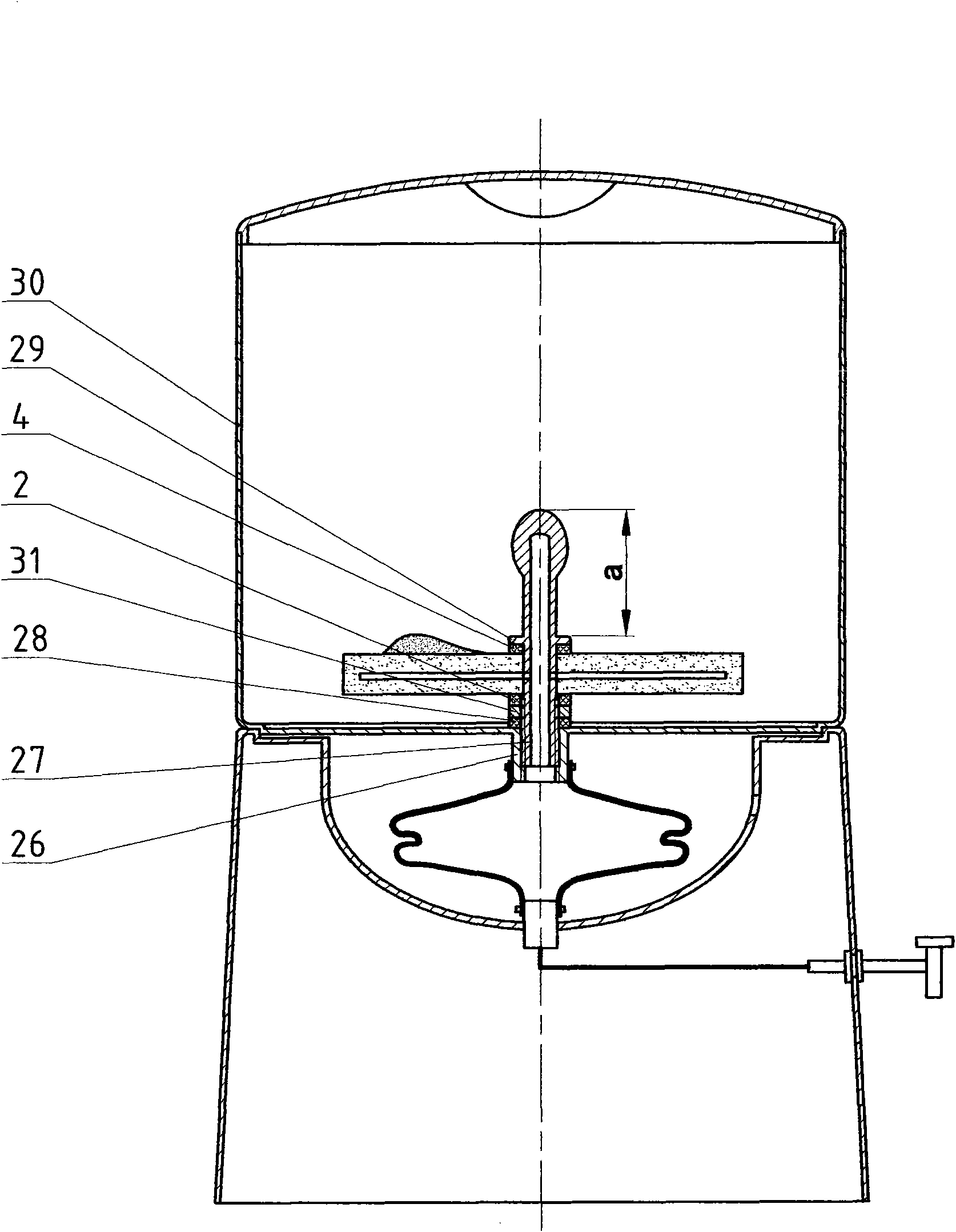

[0035] Example 3: Combination image 3 As shown, this embodiment uses a powdered water treatment material and an atmospheric water purifier of microporous ceramics, including a powdered water treatment material, a double-sided filter plate-shaped microporous ceramic, a raw water bucket 30 and a water storage bag, and the raw water bucket 30 There is a double-sided filter plate-shaped microporous ceramic at the upper part of the bottom of the double-sided filter plate, and a water flow channel is provided in the middle of the thickness of the double-sided filter plate-shaped microporous ceramic; Powder activated carbon with 60 mesh to 200 mesh; double-sided filter plate-shaped microporous ceramic is composed of a microporous ceramic component through the upper rectangular sealing ring 4, the lower rectangular sealing ring 2, the nut 31 and the joint body 27. The joint body 27 is provided with circular ribs Plate 29, the outer surface of the lower pipe body of the joint body 27 is pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com