Braking switch valve and method for switching operation state of locomotive by same

A technology for manipulating the state and switching valves, applied in the direction of brakes, brake components, pneumatic brakes, etc., can solve problems such as difficult wiring, complex structure, and influence on system pipeline design, so as to save installation quantity and space, and facilitate inspection and maintenance , the direct effect of manipulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

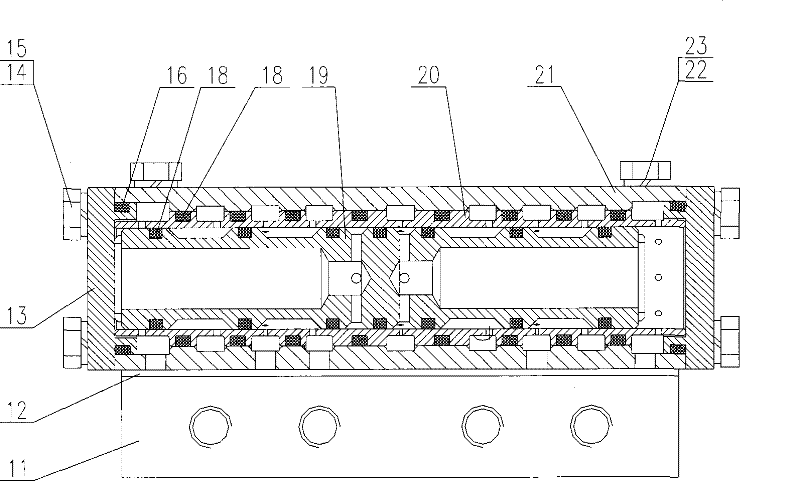

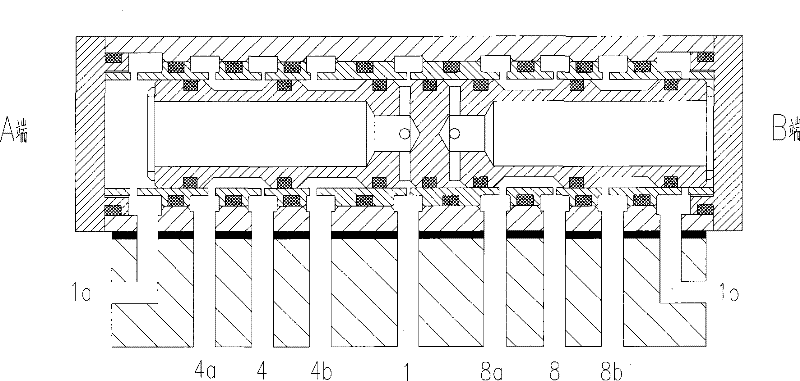

[0034] Example 1, such as Figure 1 to Figure 4 As shown, the brake switching valve has a valve body 21 , and end caps 13 are arranged at both ends of the valve body 21 . in,

[0035] A valve sleeve 20 is disposed in the inner cavity of the valve body 21 , and a plunger valve 19 that can reciprocally slide toward the end caps 13 on both sides is disposed in the inner cavity of the valve sleeve 20 . The valve body 21 is connected with the vehicle body floor through the valve seat 11 . An O-ring 16 for sealing is arranged between the valve sleeve 20 and the valve body 21 . Several O-rings 18 for sealing are arranged outside the plunger valve 19 .

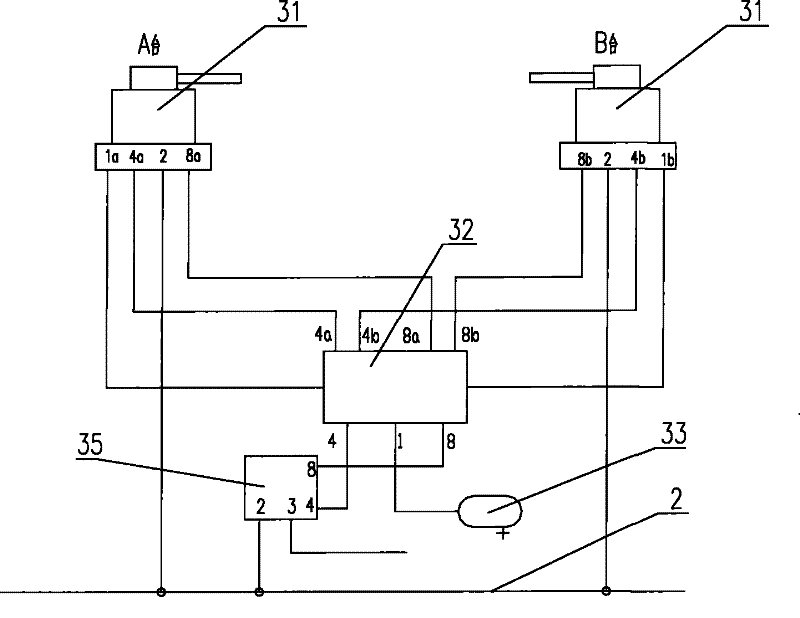

[0036] The brake switching valve 32 is connected to two brake valves 31 , a relay valve 35 and an equalizing air cylinder 33 , respectively. specifically,

[0037] There are 9 annular channels between the valve sleeve 20 and the valve body 21, including the first equalizing air cylinder pipe 1 connected to the equalizing air cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com