Wire saw for cutting hard and fragile materials and manufacturing method thereof

A brittle material, wire saw technology, applied in the new wire saw and its manufacturing field, can solve the problems of low strength resin and abrasive grain holding force, failure to form practical production applications, abrasive affecting abrasive distribution and other problems, achieving fast curing speed, Strong binding force, reducing shedding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

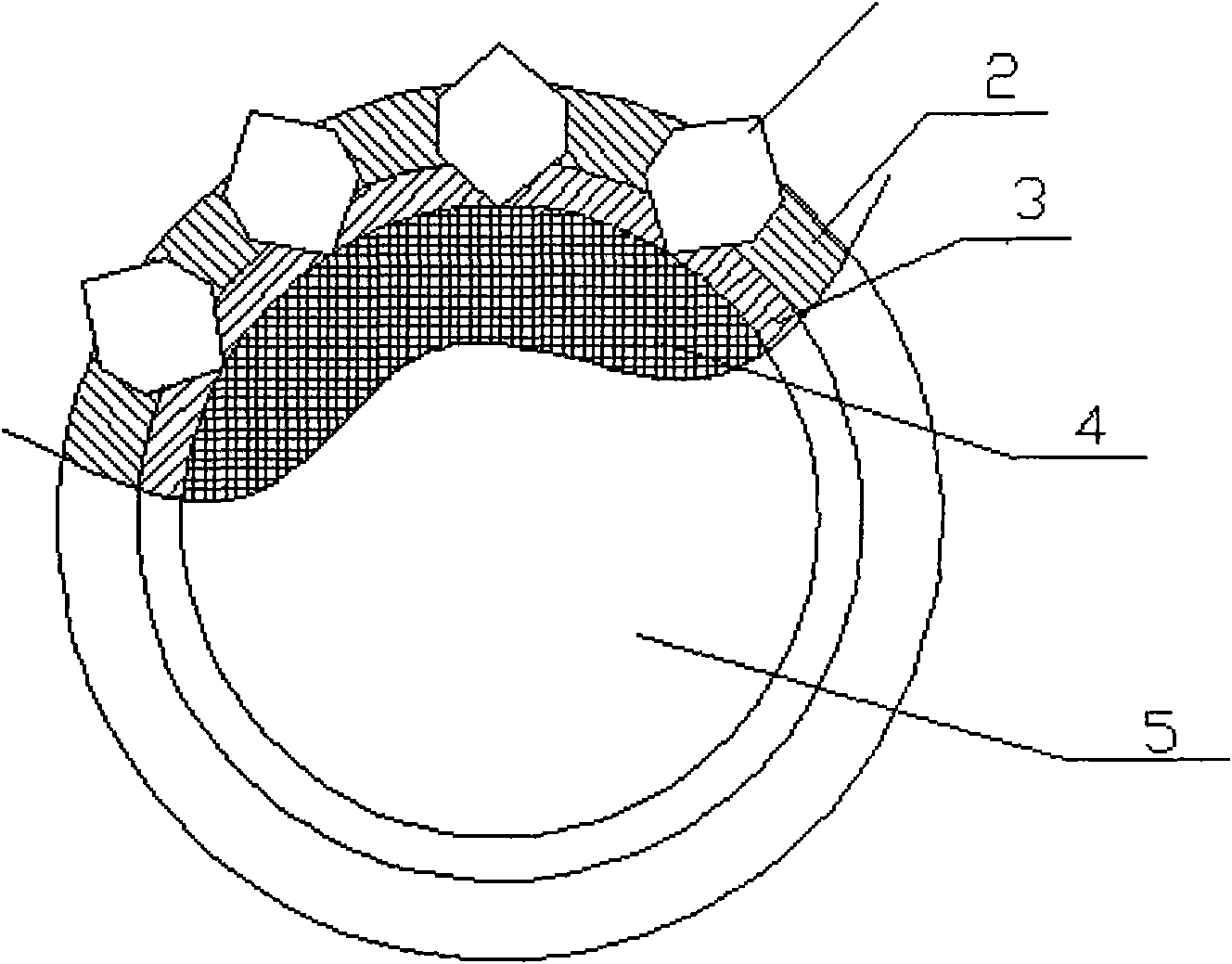

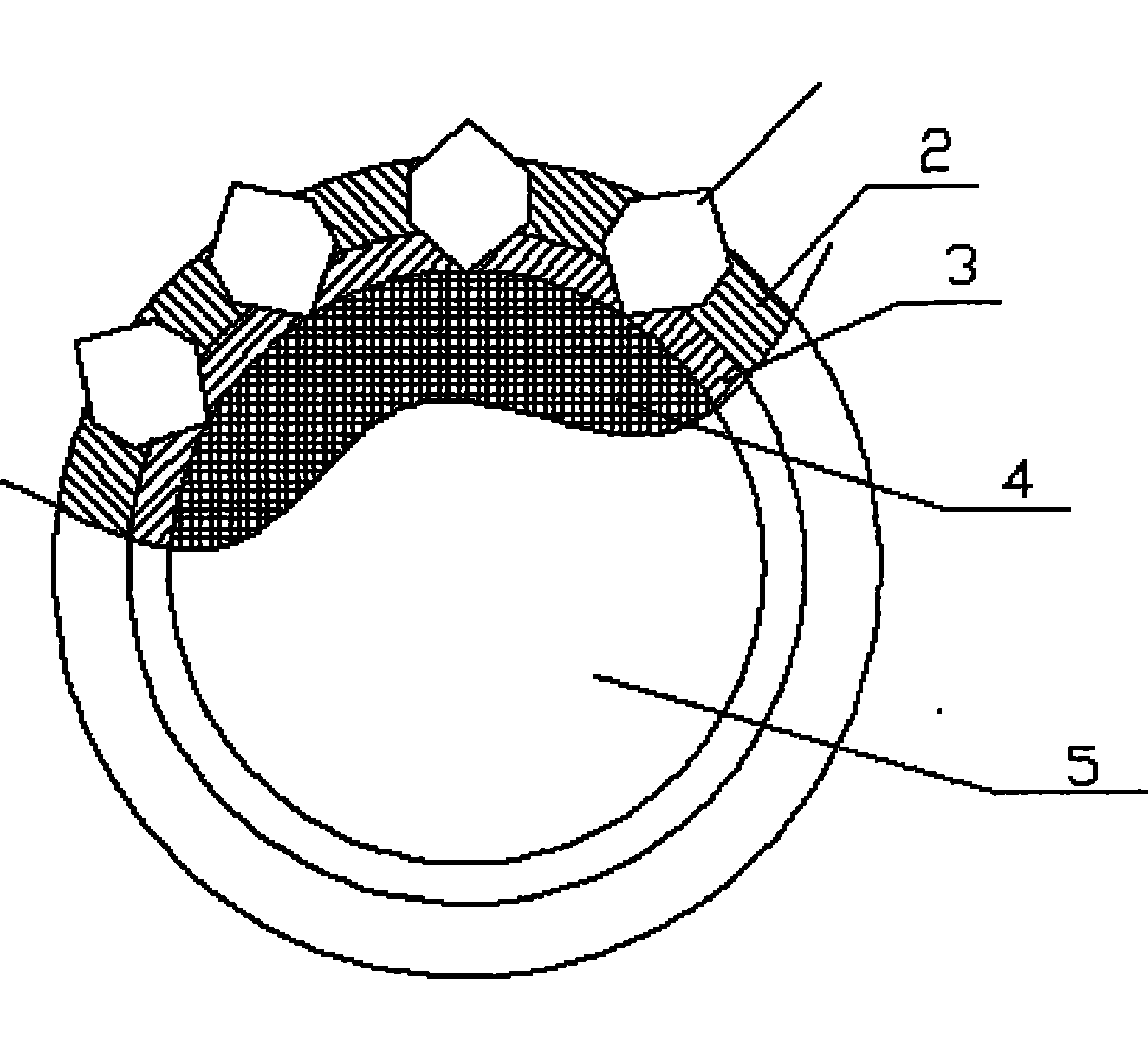

[0030] Example 1: Wire saw for cutting hard, brittle materials, including core wire, abrasive and bond. like figure 1As shown: the core wire 4 uses copper-plated piano wire; the abrasive material 1 uses diamond or CBN coated with metal on the surface; Among them, the abrasive is uniformly, continuously and single-layer distributed around the core wire, part of the abrasive is embedded in the UV resin bond, part of it is exposed outside the heat-curable resin bond to form a blade, and the rest is wrapped by the heat-curable resin.

[0031] Manufacturing process: (1) Ingredients: Weigh 10g of alumina, 10g of silicon oxide, 10g of silicon carbide, 5g of cerium oxide, 5g of chromium oxide, 120g of UV resin, mix them, and stir them evenly with a magnetic stirrer to make a UV resin binder for later use; Measure 15g of alumina, 15g of silicon carbide, 15g of cerium oxide, 15g of titanium oxide, 15g of ultrafine diamond powder, 15g of ultrafine copper powder, and 210g of thermosettin...

Embodiment 2

[0034] Embodiment 2: manufacturing process: (1) batching: weigh aluminum oxide 15g, silicon oxide 15g and silicon carbide 10g, UV resin 120g, mix, stir with magnetic stirrer and make UV resin bond for subsequent use; Weigh aluminum oxide 20g , 20g of silicon carbide, 20g of cerium oxide, 20g of ultrafine diamond powder, 20g of ultrafine copper powder, and 200g of thermosetting resin, stirred evenly with a magnetic stirrer to make a thermosetting resin binder for subsequent use. Manufacturing process (2)~(7) is the same as embodiment 1.

[0035] In this embodiment, a copper-plated musical instrument wire with a diameter of 0.10 mm is used. The abrasive material is titanium-plated artificial diamond with an average particle size of 24 microns. The UV resin is an acrylic resin, and the thermosetting resin is a phenolic resin.

[0036] The technical parameters of the wire saw produced in this embodiment are shown in Table 1 below, and the cutting performance indicators are shown i...

Embodiment 3

[0037] Embodiment 3: manufacturing process: (1) batching: weigh aluminum oxide 20g, cerium oxide 15g and chromium oxide 15g, UV resin 150g, mix, stir with magnetic stirrer and make UV resin binder for subsequent use; Weigh aluminum oxide 30g , 20g of silicon carbide, 10g of titanium oxide, 25g of ultrafine diamond powder, 10g of ultrafine copper powder, 220g of thermosetting resin, stir evenly with a magnetic stirrer to make a thermosetting resin binder for future use. Manufacturing process (2)~(7) is the same as embodiment 1.

[0038] In this embodiment, a copper-plated music wire with a diameter of 0.14 mm is used. The abrasive is copper-plated artificial diamond with an average particle size of 30 microns. The UV resin is an acrylic resin, and the thermosetting resin is a polyimide resin.

[0039] The technical parameters of the wire saw produced in this embodiment are shown in Table 1 below, and the cutting performance indicators are shown in Table 2 below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com