Multifunctional drum-type iron dressing machine

A drum-type, multi-purpose technology, applied in the directions of magnetic separation, solid separation, chemical instruments and methods, etc., can solve the problems of high operation cost, environmental protection, dust, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

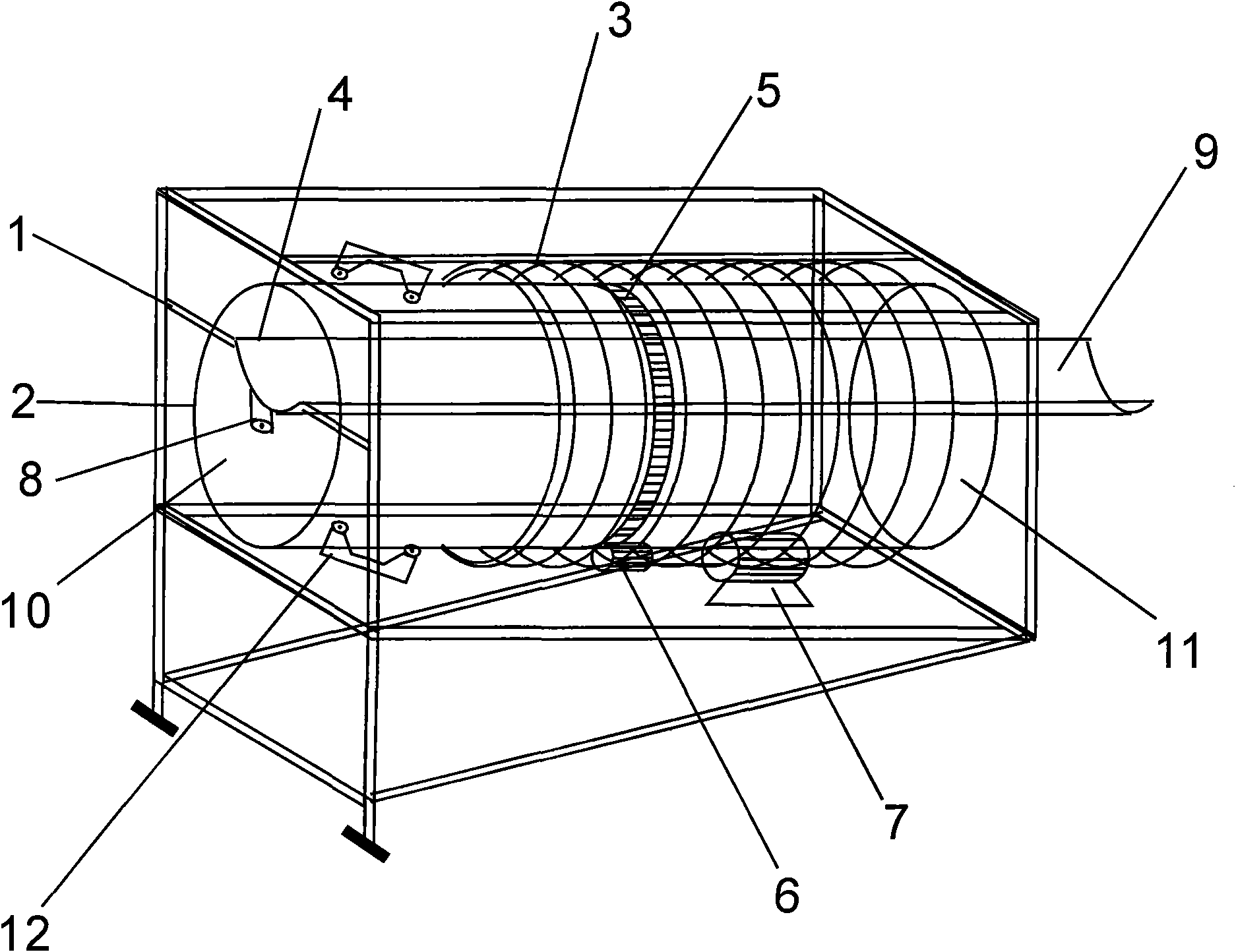

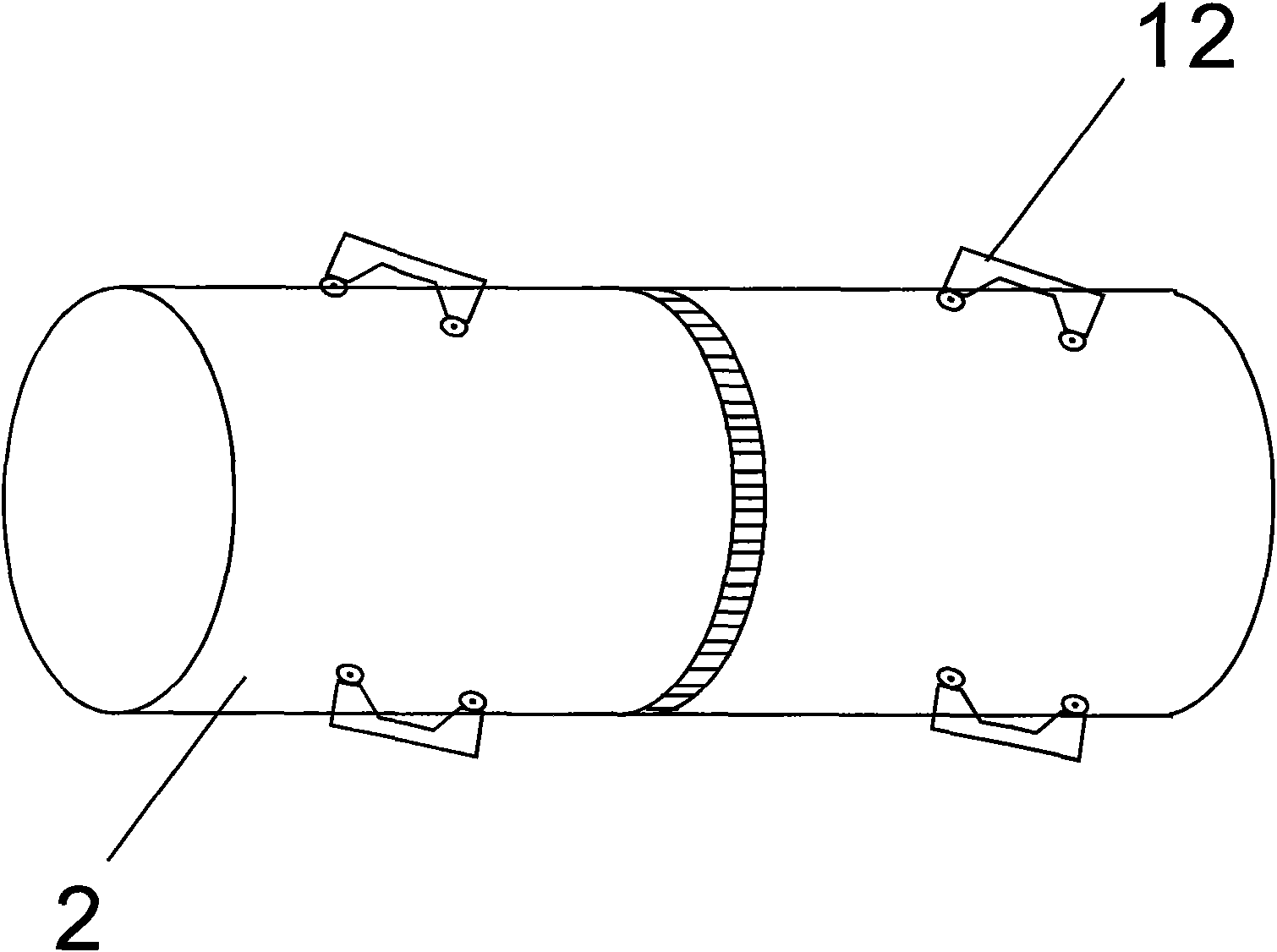

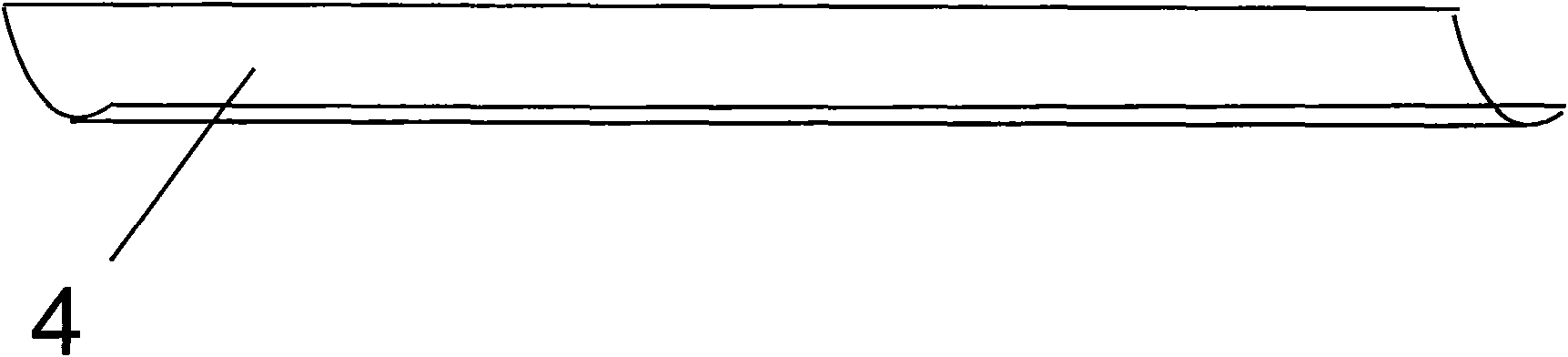

[0011] Such as figure 1 , figure 2 , image 3 As shown, the multipurpose drum type iron separator provided by the present invention comprises a frame 1 and a drum 2 such as figure 1 Shown, drum 2 has four pulley frames 12 fixed rolling operations, wherein pulley frames 12 are fixed on the frame 1, as figure 1 As shown, the inner center of the drum 2 is provided with a vibrating chute 4 for the convenience of selecting fine powder to slide out, and the other end of the vibrating chute 4 is a fine powder discharge port 9, such as figure 1 Shown, cylinder 2 outside is provided with C shape strong magnetic bed 3 and is fixed on the inner side of frame 1.

[0012] Such as Figure 4 , Figure 5 Shown, above-mentioned C-shaped strong magnetic bed 3 is made up of many C-shaped magnets. Such as Figure 4 Shown C shape strong magnetic bed 3 is fixed on the side of cylinder outside, as Figure 5 As shown, the above-mentioned magnets are arranged vertically with each other at int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com