Method for producing transparent substrate double-sided conductive film of touch control circuit

A technology of transparent substrates and touch circuits, which is applied to circuits, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problems of consuming process man-hours and material costs, and achieve the effects of reducing costs, reducing man-hours, and simplifying the layout process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

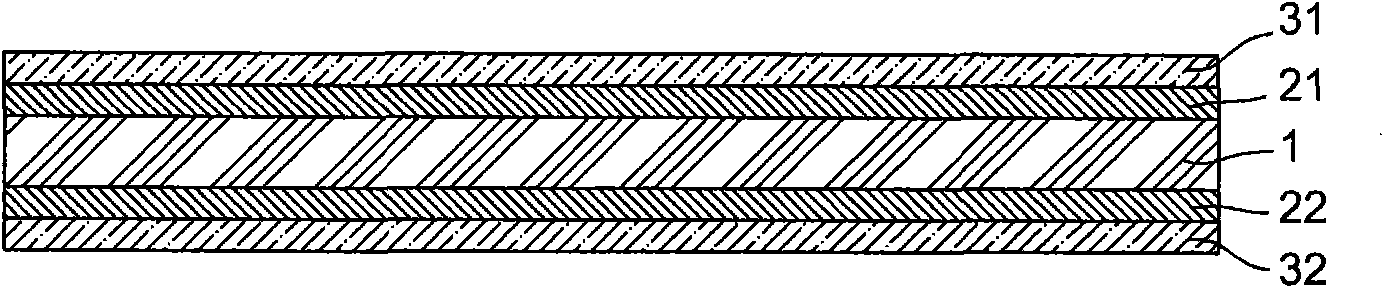

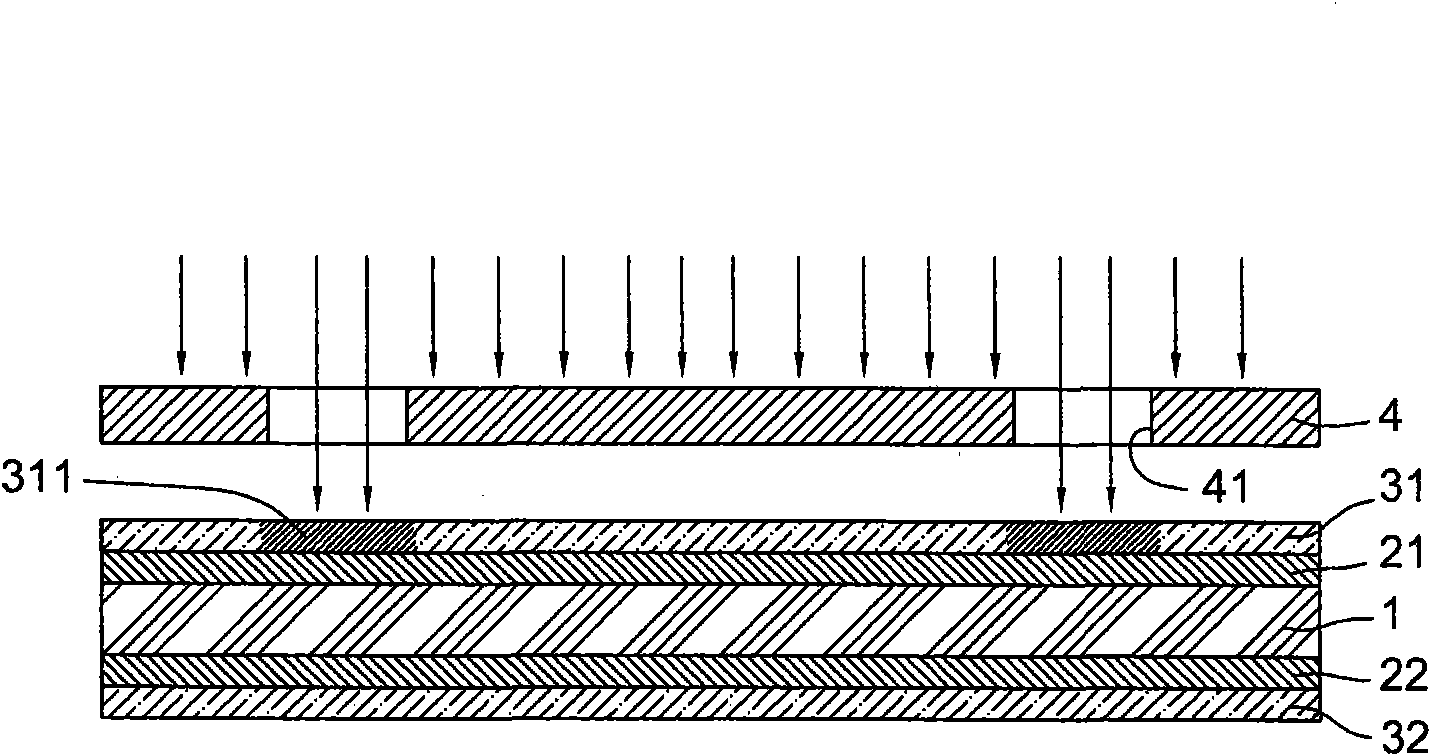

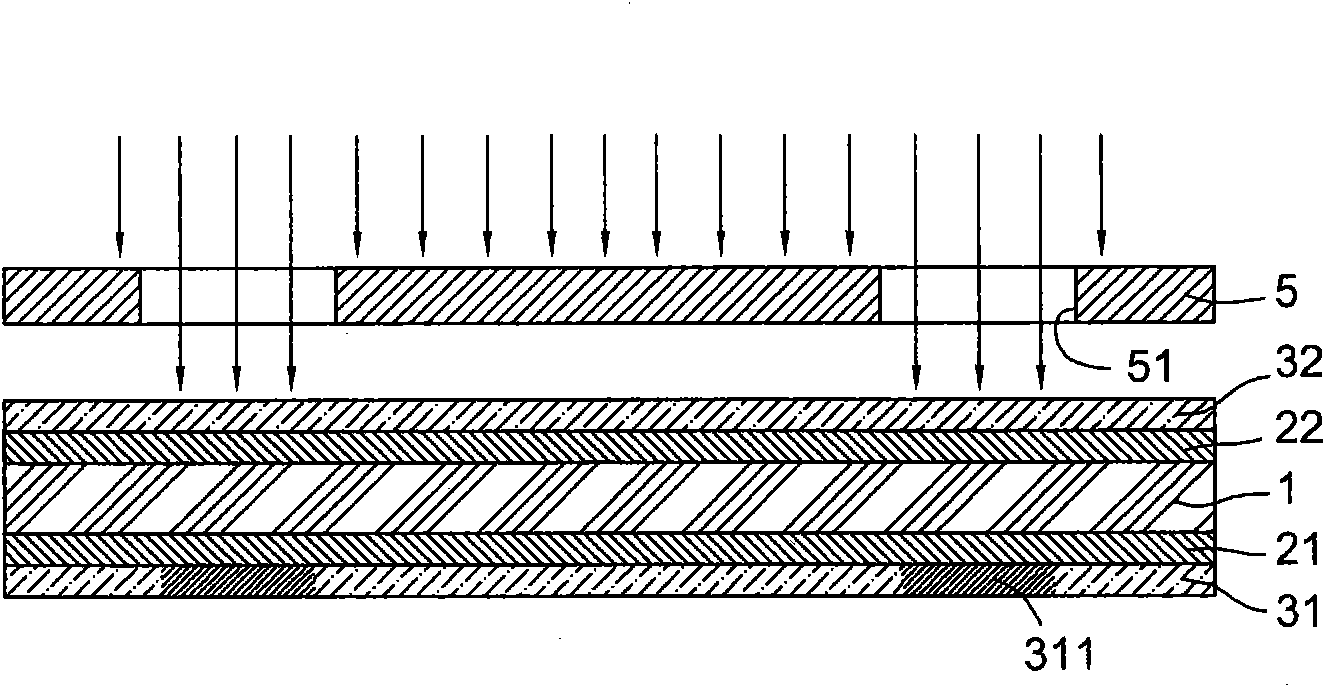

[0035] The steps of the manufacturing method of the double-sided conductive film of the transparent substrate of the touch circuit of the present invention and the effects that can be produced are described in detail as follows with a preferred embodiment in conjunction with the accompanying drawings:

[0036] see figure 1 As shown, it is a cross-sectional view of the configuration state of the embodiment of the present invention, and cooperates with Figure 2 to Figure 6 The method for preparing the double-sided conductive film of the transparent substrate of the touch circuit of the present invention includes the following steps:

[0037] (1) A transparent substrate 1 is placed in the sputtering equipment, and a first conductive substrate layer is formed on the first surface of the transparent substrate 1 by vacuum sputtering; in this implementation, the transparent substrate 1 The first surface is located on the top surface of the transparent substrate 1, and the first con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com