Reaction moment balance transmission system for single rotating motor

A transmission system and counter-torque technology, applied in the field of counter-torque balance transmission systems of single-rotation motors, can solve problems affecting power efficiency, propulsion device rotation, power cycle, etc., and achieve the effects of simple structure, low vibration and noise, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

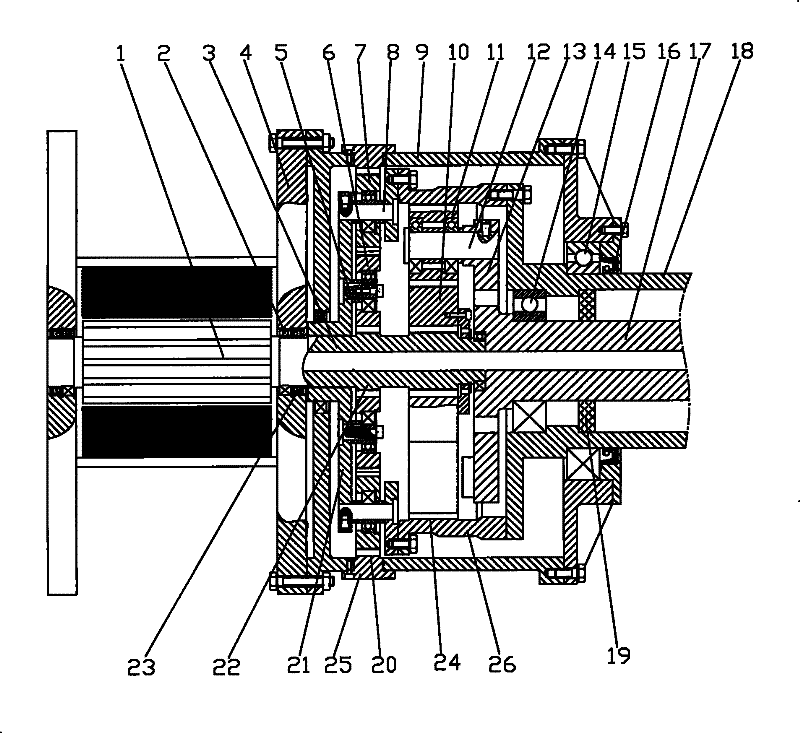

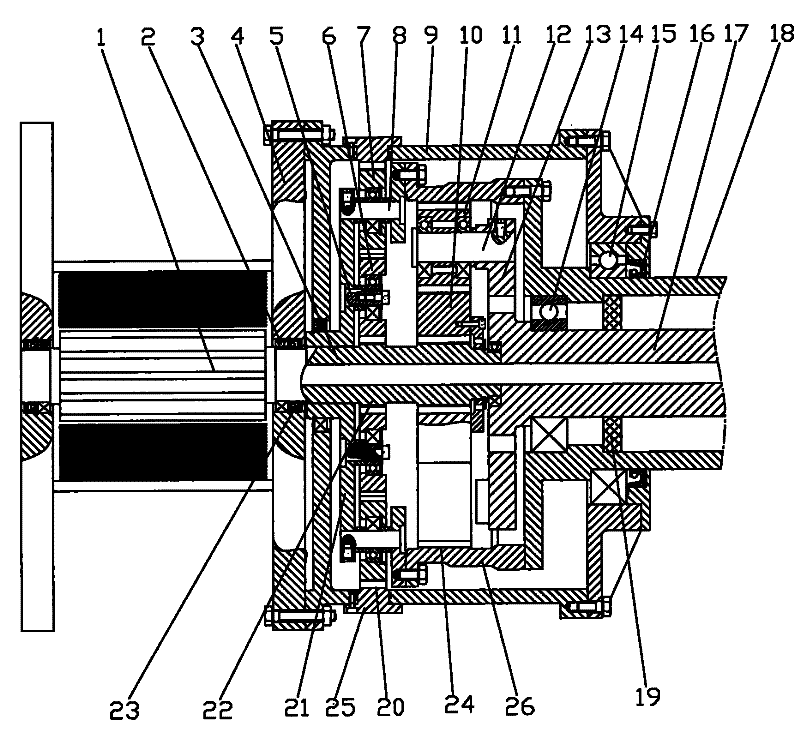

[0021] Accompanying drawing is the structure schematic diagram of the present invention, as shown in the figure: the single-rotation motor anti-torque balance transmission system of the present embodiment comprises box body 9, the first planetary gear transmission system and the second planetary gear transmission system located in the box body 9 , the box body 9 is fixedly connected to the end cover 4 of the single-rotation motor;

[0022] The first planetary gear transmission system includes a first sun gear 22, a first planet carrier 21, a planetary gear I6, a planetary gear II7 and a first ring gear 20, and the first sun gear 22 is connected to the rotor 1 of a single-rotation motor. The circumferential direction is fixedly matched, and the planetary gear I6 and the planetary gear II7 are arranged side by side along the radial direction of the first planetary carrier 21 and are self-rotatingly matched with the first planetary carrier 21. The same as the prior art, there are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com