Combination foundation of large-scale tower mast type mechanical equipment

A technology of mechanical equipment and combined foundation, applied in infrastructure engineering, construction, etc., can solve problems such as large volume, waste of resources, environmental pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

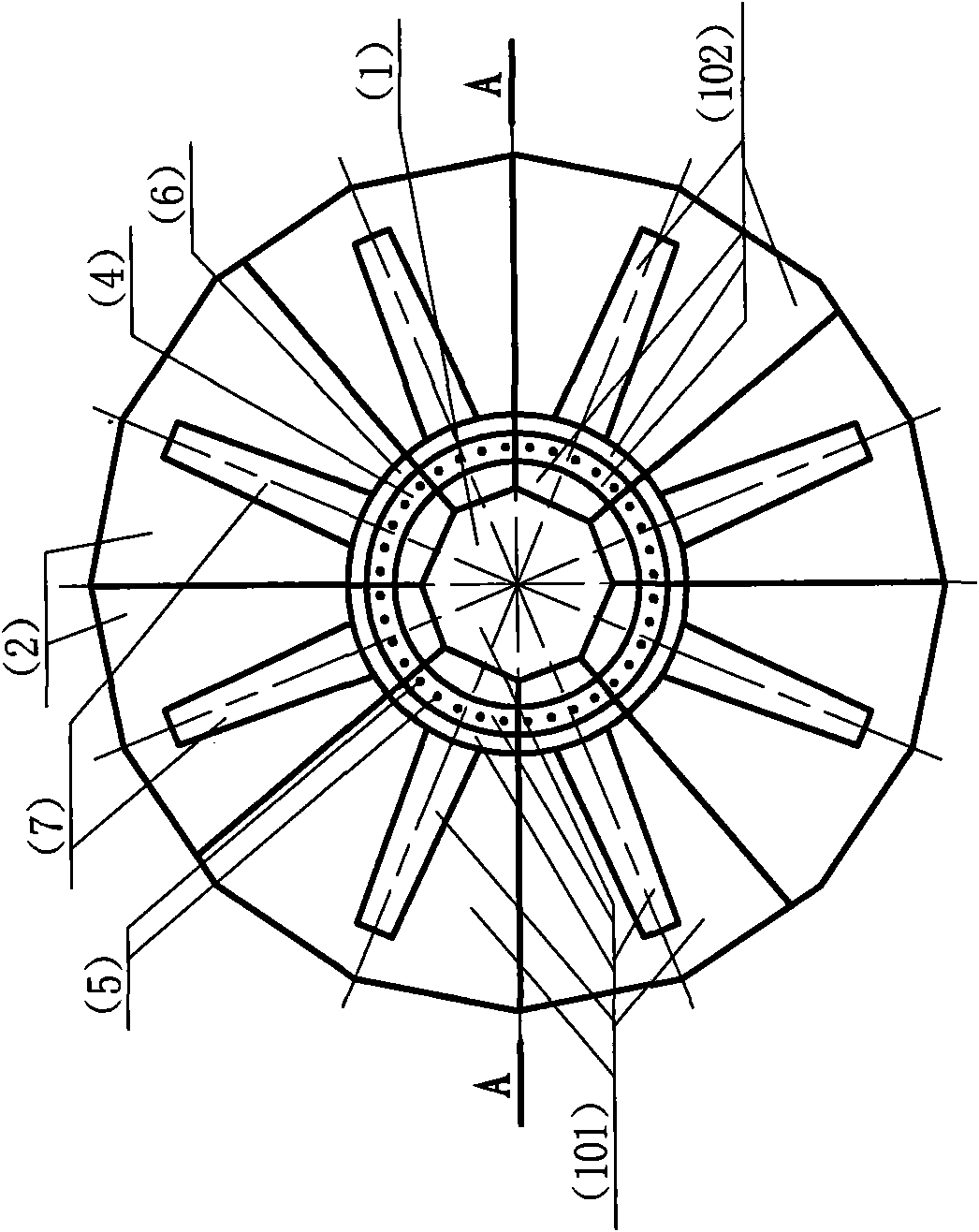

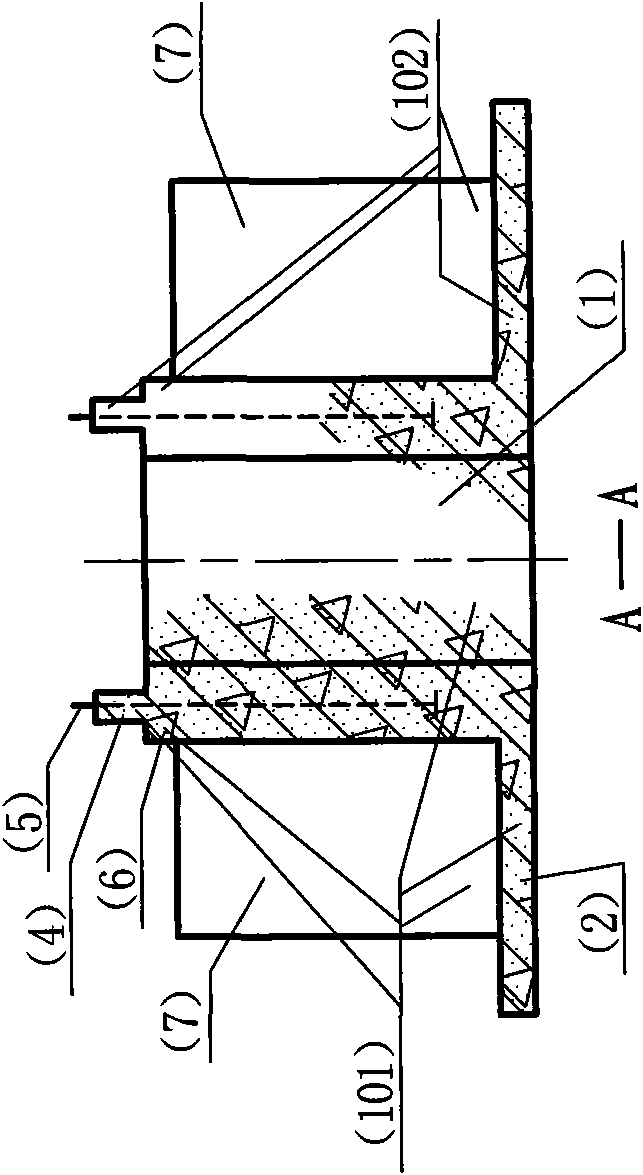

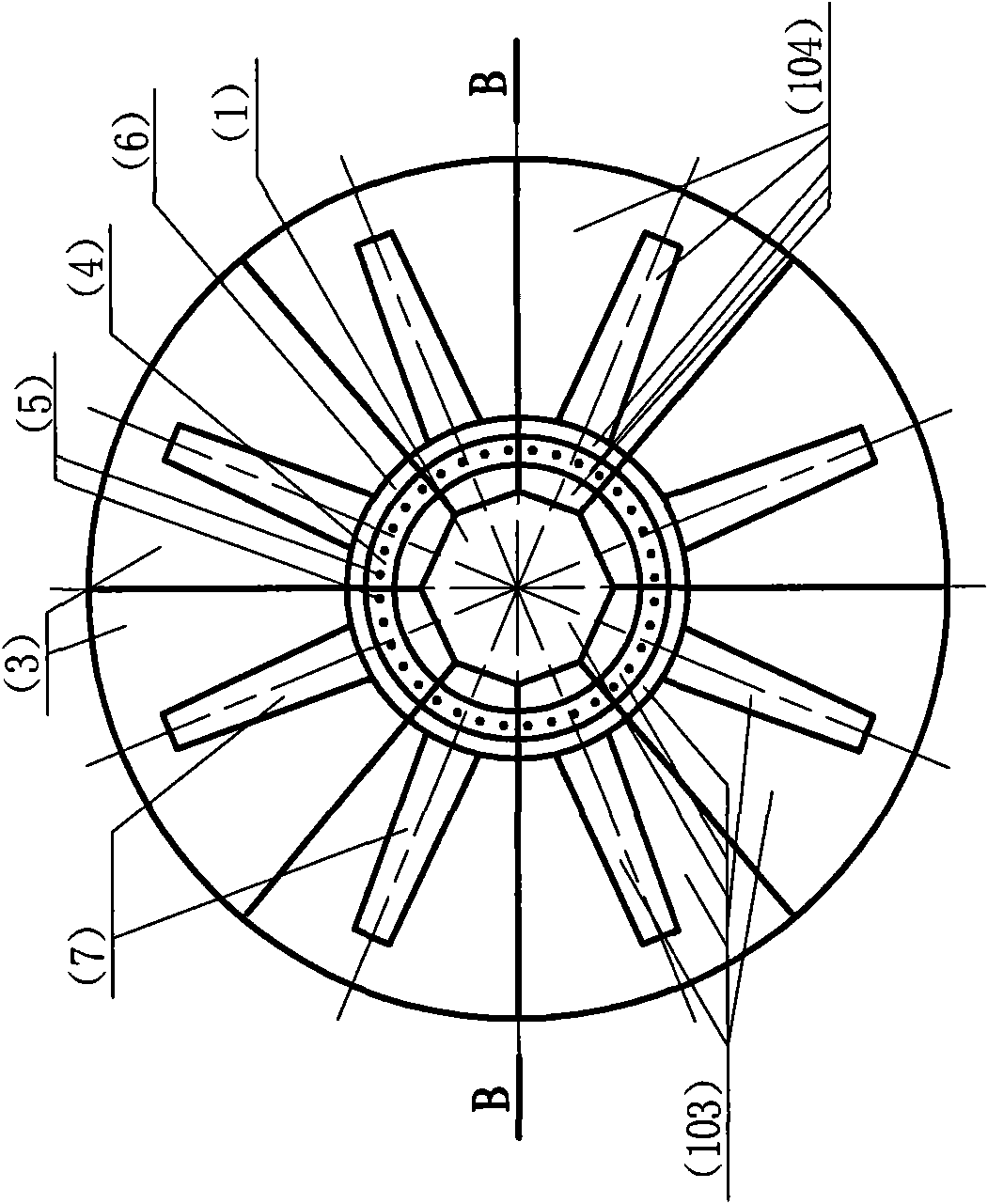

[0084]No. 1 regular polygonal foundation 101 or No. 1 beam-slab composite structure 102 or circular foundation No. 1 103 or No. 2 beam-slab composite structure 104 or regular polygonal foundation No. 2 105 or No. 3 beam-slab composite structure 106 or circle of the present invention No. 2 foundation 107 or No. 4 beam-slab composite structure No. 108 is assembled by concrete prefabricated components according to the set position, and its plane position shape is as follows: figure 1 , 2 , 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 14, 15, 16, 17, 18, 19, 20.

[0085] The present invention adopts a horizontal combined prestressed steel strand connection system at the upper and lower parts along the axis of the foundation beam No. 1 No. 7 or the foundation beam No. 2 No. 8; according to the structural requirements, the upper single and lower orders, and the upper single and lower multiple steel strands are adopted. The line channel 39 connects all the prefabricated concrete components ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com