Dual channel device for treating aqueous discharge plasma

A discharge plasma and water treatment device technology, applied in the field of wastewater treatment, can solve the problems of limited oxidation capacity and selectivity, unsafe storage and use of reagents, complex equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

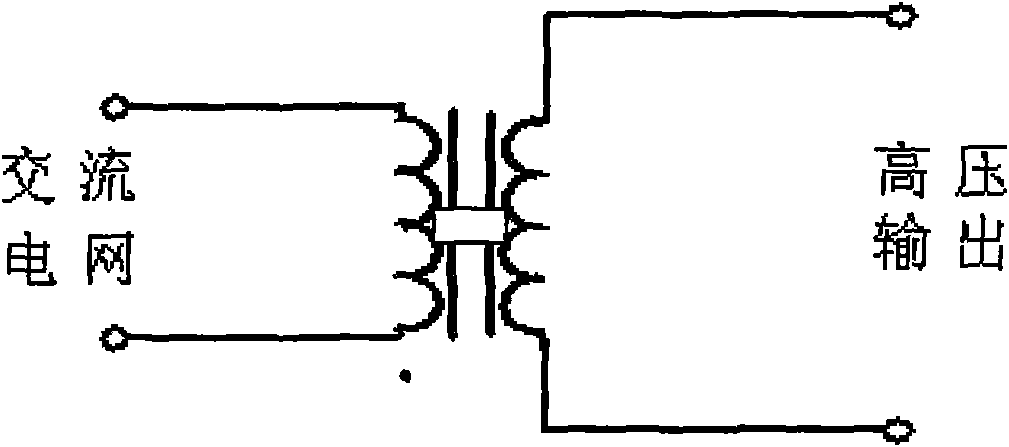

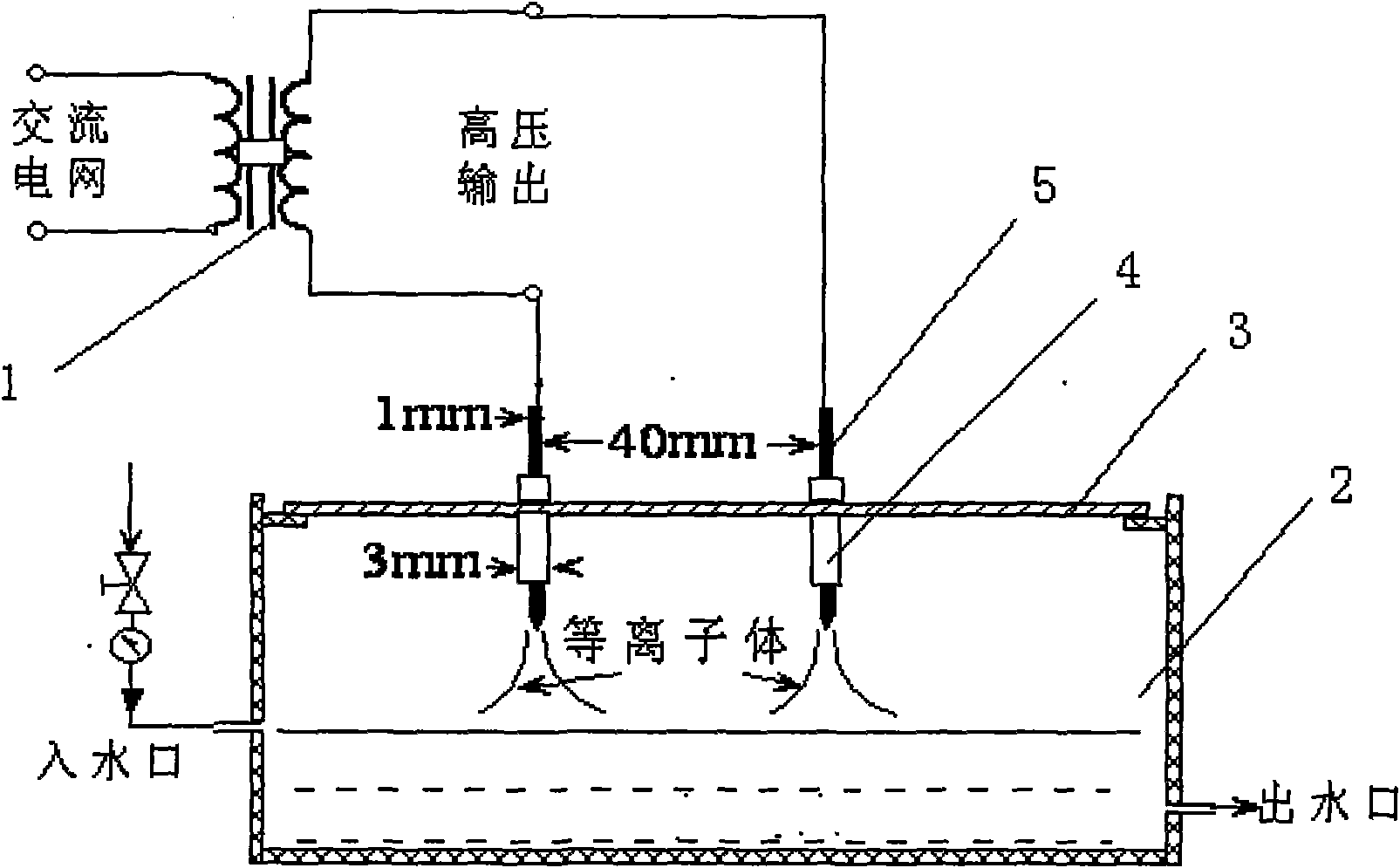

[0021] The dual-channel discharge plasma water treatment device uses a pair of electrodes, which are thoriated tungsten alloys, with a diameter of 1mm and sharpened tips. The insulating sleeve can be polytetrafluoroethylene, with a diameter of 3mm and a thickness of 1mm. The electrodes are installed inside the insulating sleeve. The distance between the discharge ends of the electrodes is 40mm, and the flame-retardant, heat-resistant and non-deformable insulation board is made of cement asbestos board with a thickness of 10mm. The distance between the discharge end and the water surface is 0.5mm. The power supply adopts a flux leakage transformer, the input AC voltage is 220V, the output AC no-load voltage is 15kV, and the output power is 20-30W. The simulated wastewater to be treated is a methyl violet solution with a concentration of 100 mg / L and a volume of 100 ml, which is treated statically in a water tank. The results are shown in Table 1.

[0022] Table 1

[0023] ...

experiment example 2

[0025] The dual-channel discharge plasma water treatment device adopts two pairs of electrodes, the two pairs of electrodes are arranged in parallel with a distance of 50mm, and the two do not affect each other; the distance between the discharge end and the water surface is 8mm. The power supply adopts a magnetic flux leakage transformer, the input AC voltage is 220V, the output AC no-load voltage is 15-18kV, and the total output power is 60-75W, which are provided to two pairs of electrodes respectively in two circuits. The simulated waste water to be treated is an acid purple solution with a concentration volume of 40 ml, which is treated statically in a water tank. The results are shown in Table 2.

[0026] Table 2

[0027] Pollutants

[0028] Experimental example 1 and experimental example 2 illustrate that the dual-channel discharge plasma water treatment device of the present invention can generate plasma to treat water; Secondary pollution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com