Two-column parallel high-speed non-PVC membrane full automatic bag making, filling and sealing machine

An automatic manufacturing and sealing machine technology, applied in the field of medical machinery, can solve the problems of a large increase in equipment length, technical difficulty, and equipment adjustment difficulty, and achieve the effect of doubling the output, compact structure and doubling production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in conjunction with the accompanying drawings of the above-mentioned embodiments.

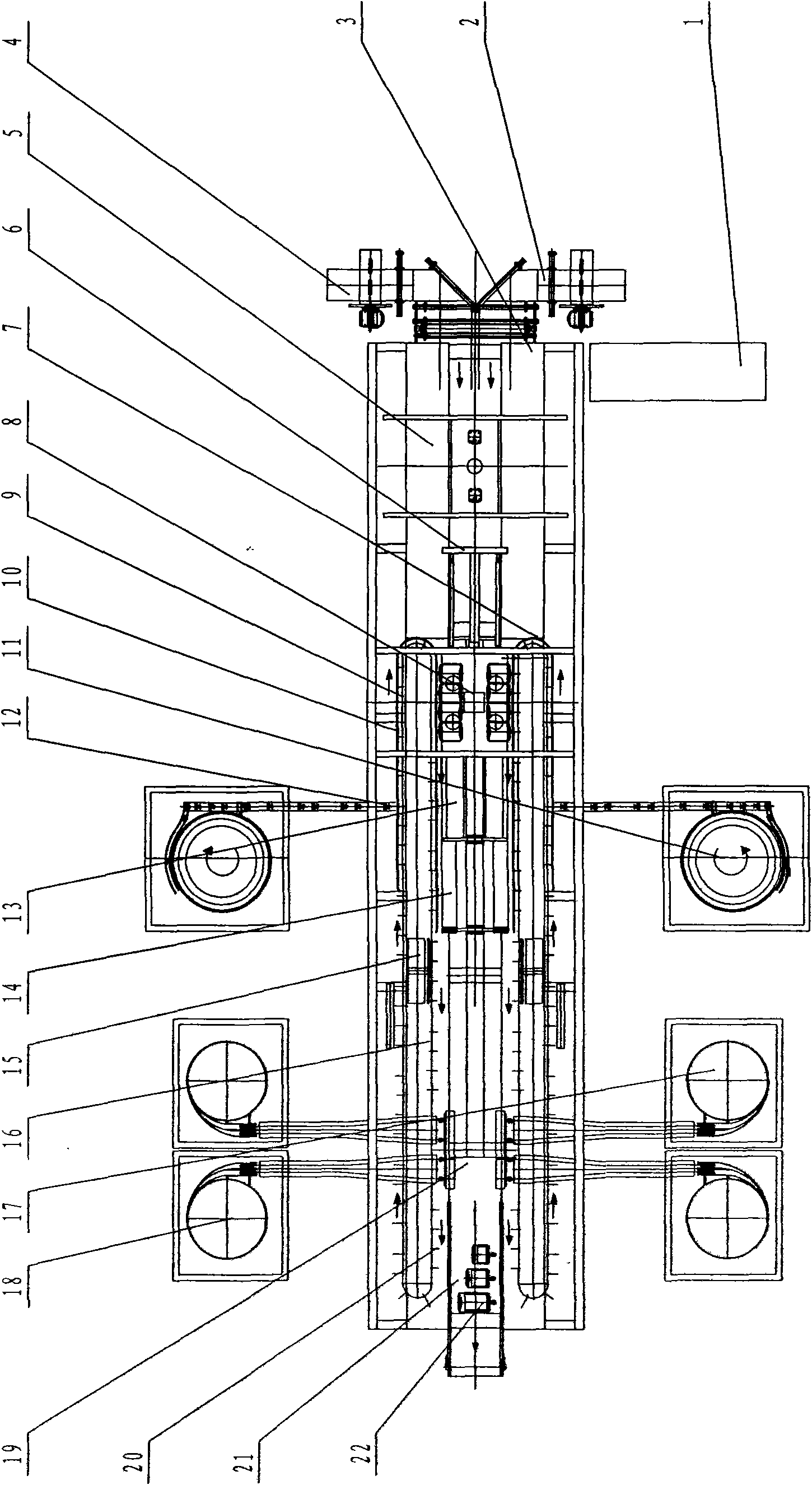

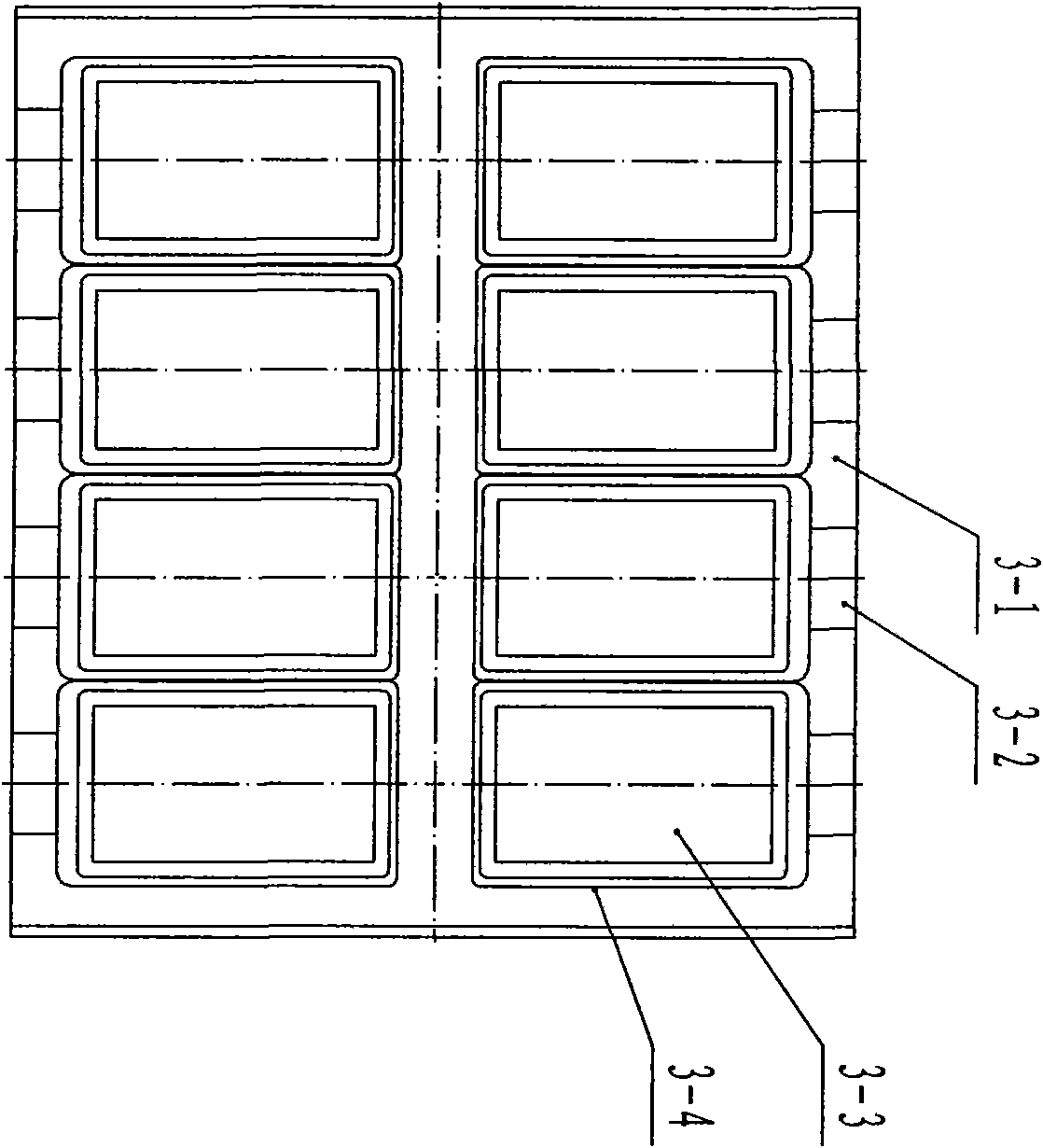

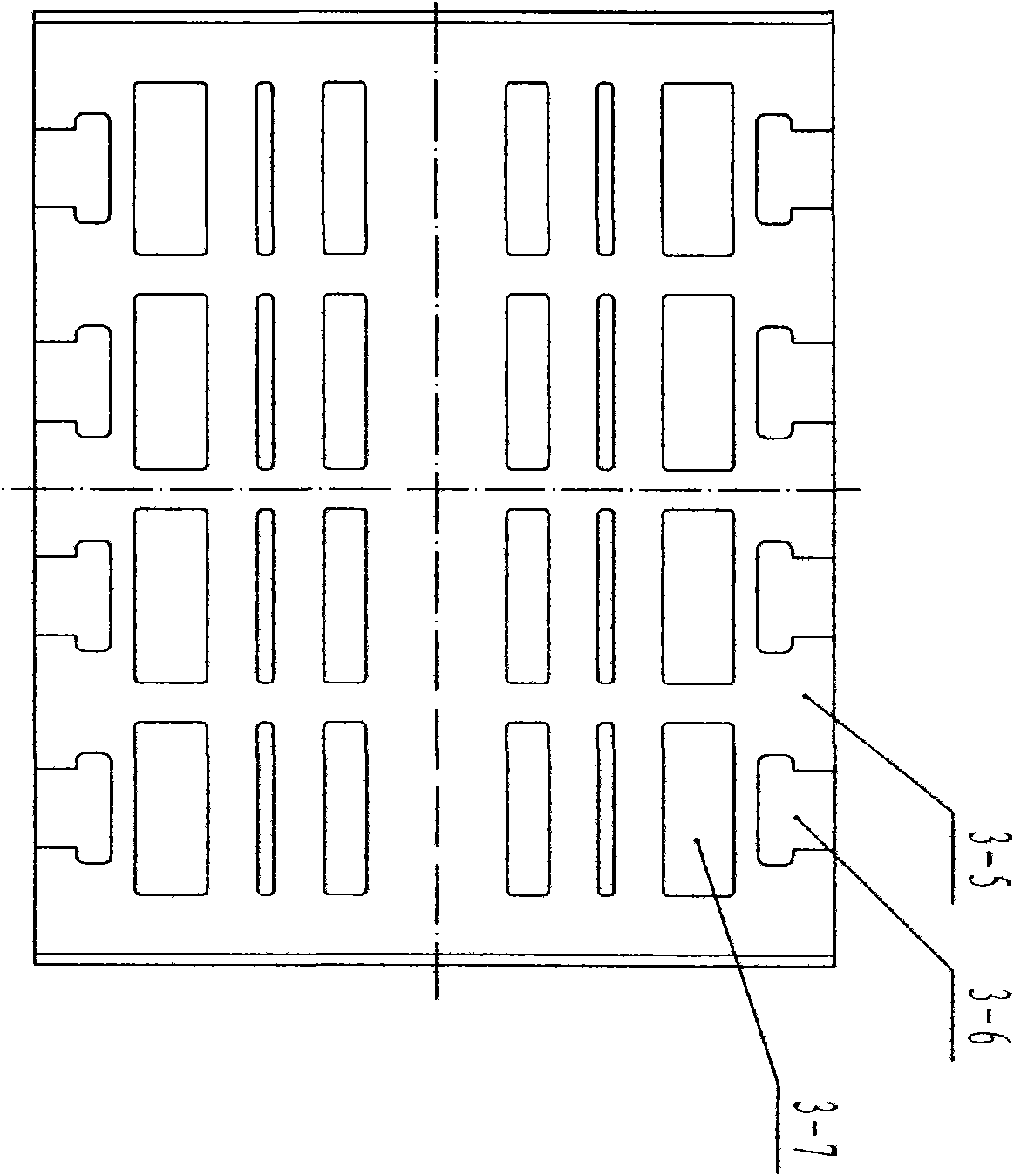

[0026] Such as figure 1 As shown, the two-row parallel high-speed non-PVC film automatic bag making and filling machine described in the present invention includes an integral frame 3, a power distribution cabinet 1, an endless transmission timing belt 9, a bag making mechanism and a potting and sealing mechanism, wherein the bag making The mechanism includes a film-on mechanism 4, a bag-forming mechanism 8, and an opening tube welding mechanism 13. The filling and sealing mechanism includes a filling mechanism 16, a sealing mechanism 19, and a bag body output mechanism 20. The endless conveyor timing belt 9 is provided with a mouth tube clamp, and the ring Conveying synchronous belt 9 has two sets that are vertically side by side, equipped with station assembly respectively. The parallel production equivalent to two production lines can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com