Rapid installation and rapid exchange system of electric automobile battery and rapid installation and rapid exchange method thereof

An electric vehicle and battery technology, applied in electric vehicle charging technology, electric vehicle, battery/battery traction, etc., can solve problems such as difficulty in implementation, large battery pack size, and limited battery installation space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be specifically described below in conjunction with the accompanying drawings.

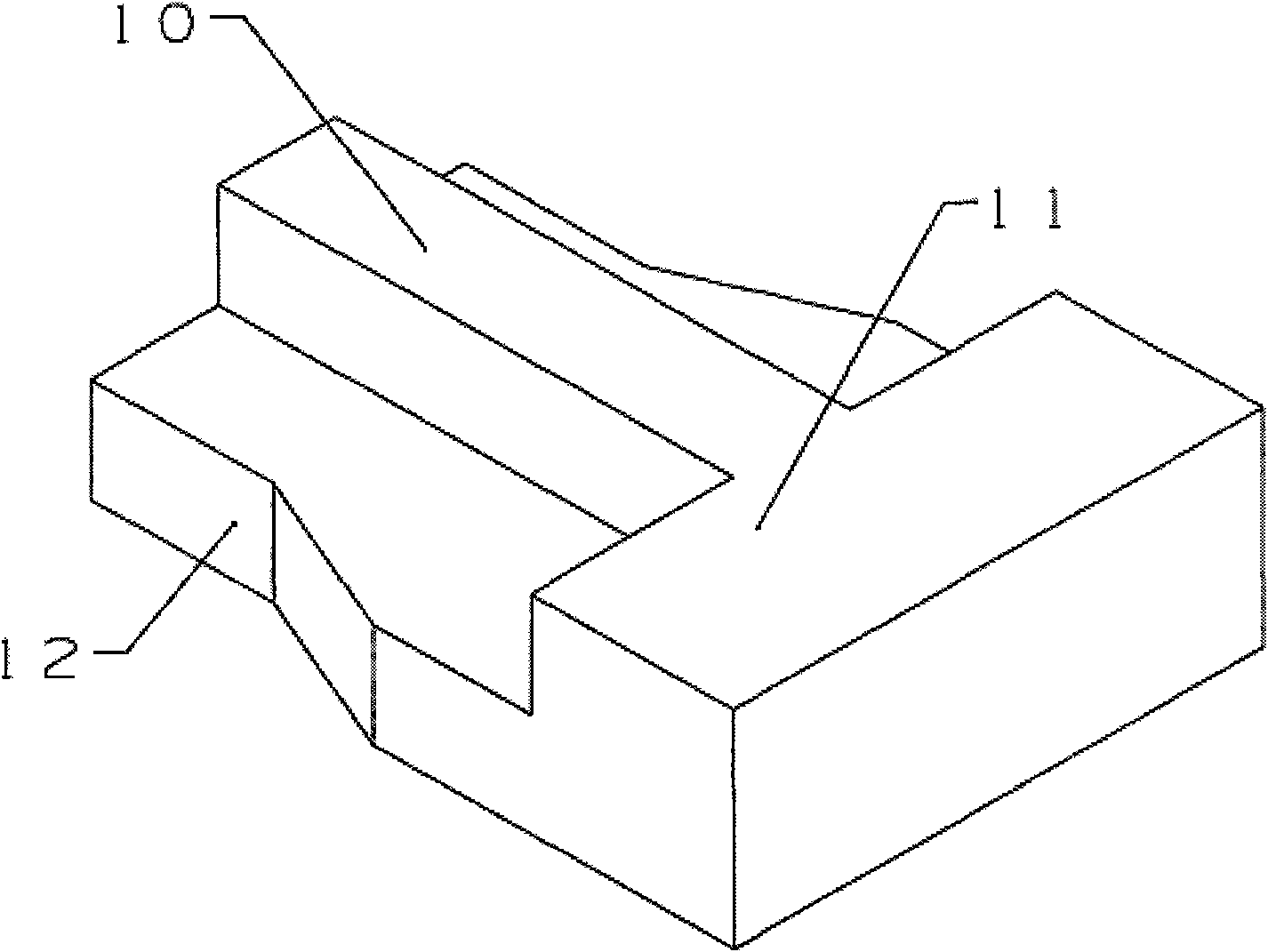

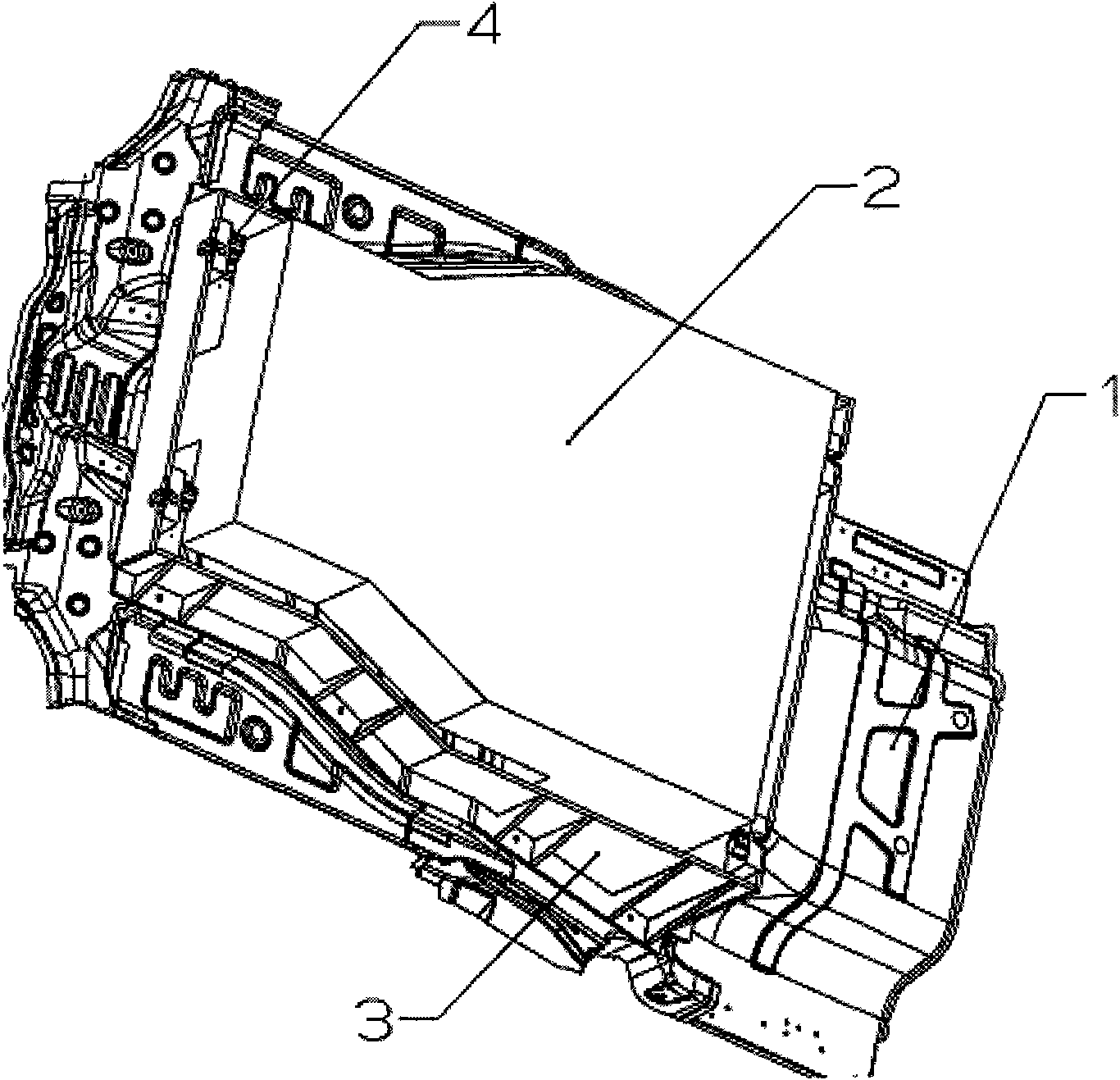

[0033] Such as figure 1 , the battery pack 2 is designed according to the shape of the body floor 1 in order to maximize the use of space. The floor of the fuel car is raised in the middle channel, fuel tank, etc. to accommodate parts such as exhaust pipes and fuel tanks. In electric vehicles, these parts can be eliminated, so the shape of the battery pack 2 can be designed to fit the body completely, so that It can effectively use the space, meet the battery capacity requirements of electric vehicles, and increase the driving range.

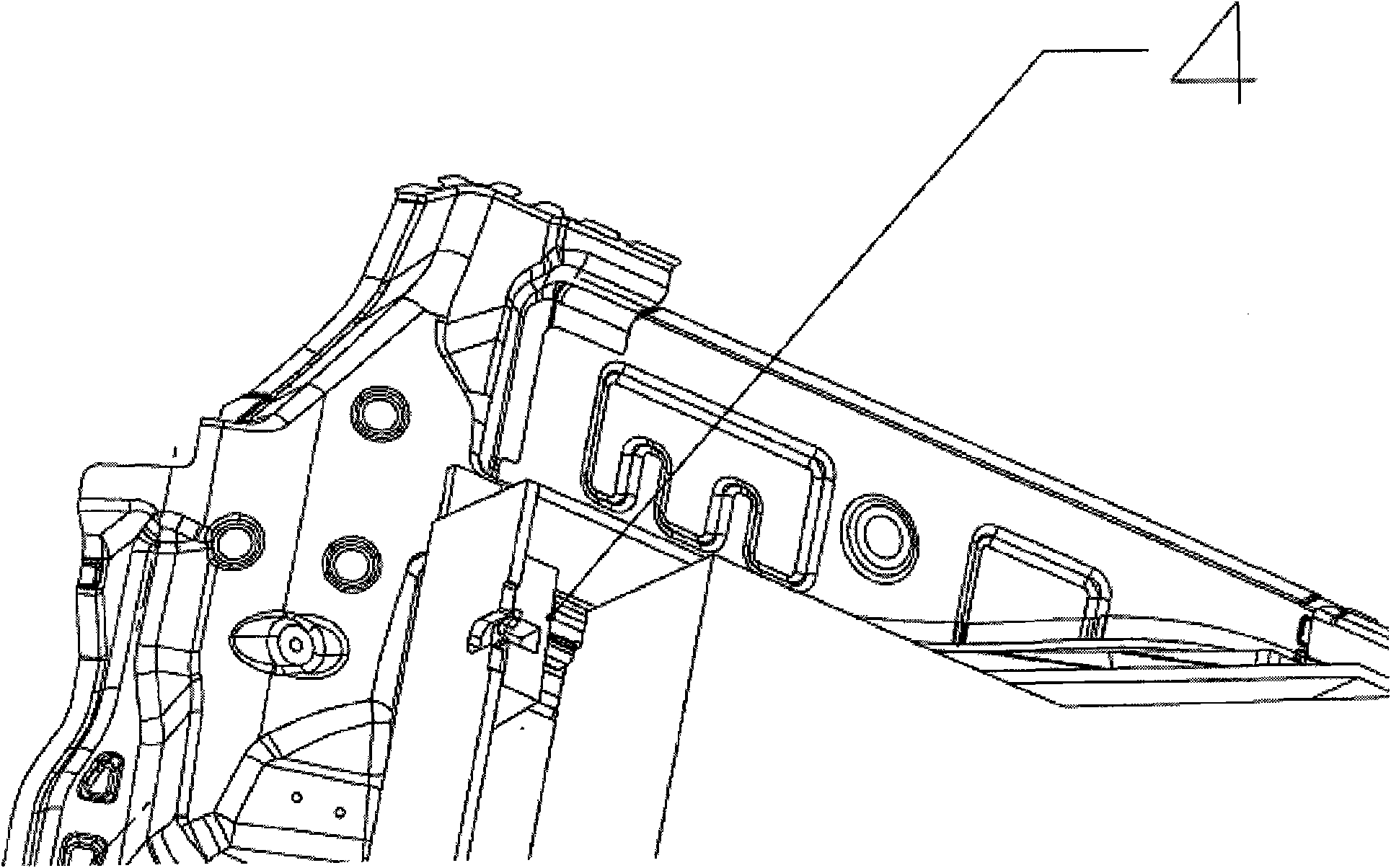

[0034] Such as figure 2 , 3 Looking up from the bottom of the floor, the battery pack protection frame 3 can be an aluminum alloy part, which is installed on the longitudinal beams and crossbeams under the body floor 1 through bolts, or the body floor 1 can be directly stamped and formed. The protective frame 3 protects the bat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com