Alloy ingot casting mould with cooling device and ingot casting method thereof

A technology of alloy ingot and cooling device, applied in the field of smelting, can solve the problems of small volume of hoisting iron core, long cooling time, easy explosion of alloy ingot, etc., so as to improve product quality, product yield, surface finish and flatness Increase and decrease the effect of elemental composition segregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

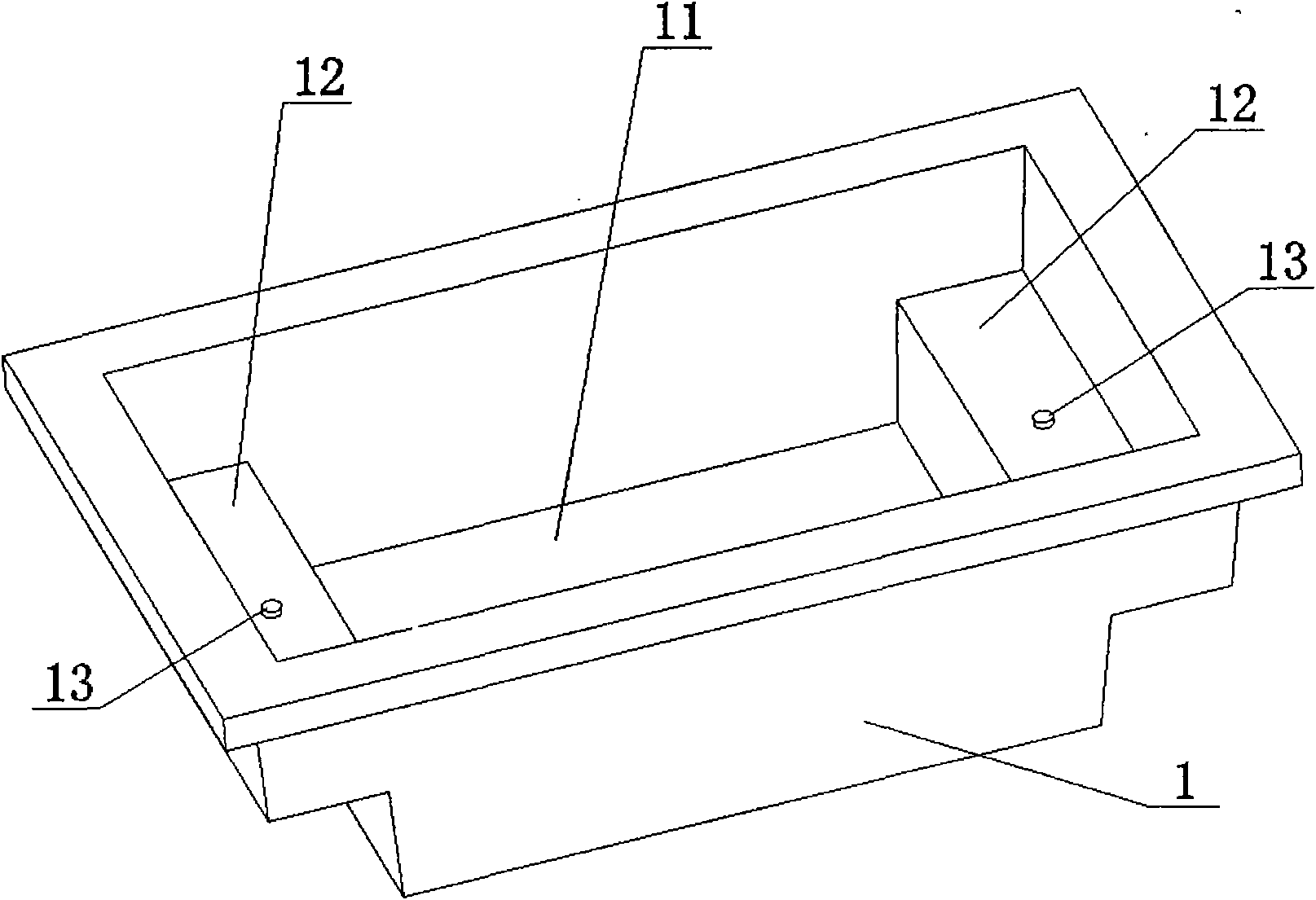

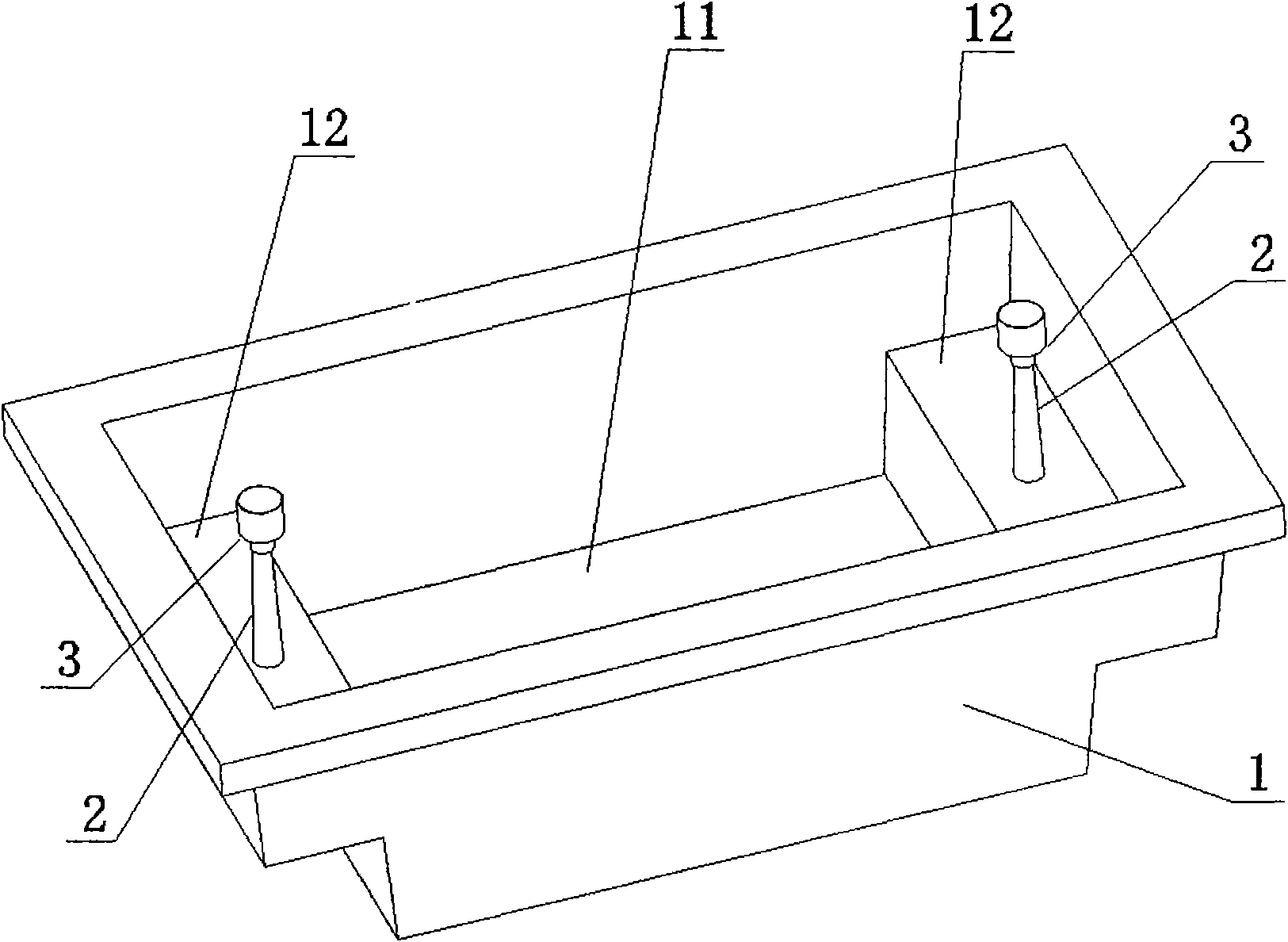

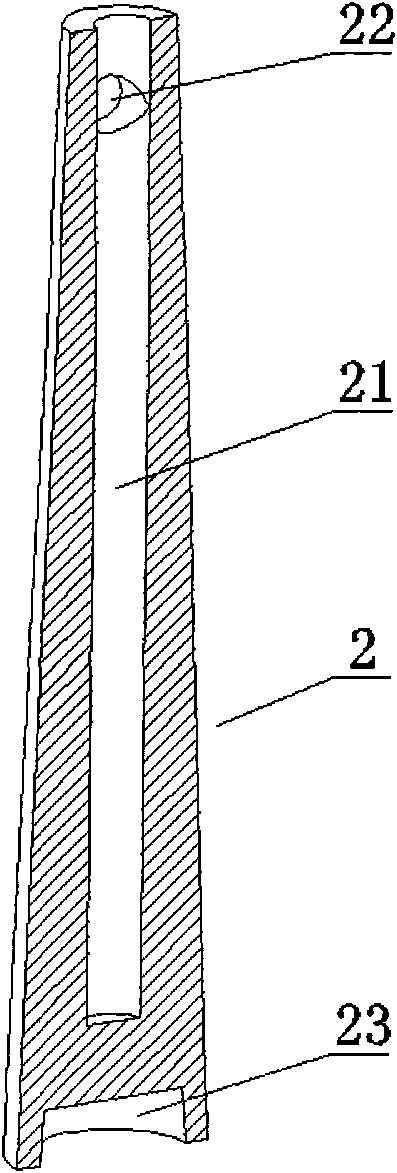

[0024] Embodiment 1: as figure 1 , 2 , 3 and 4, a alloy ingot mold with a cooling device, it includes a pouring trough 1 with a small mouth at the bottom of the inner cavity 11 and a large inverted convex glyph 1, and positioning protrusions are set on the steps 12 on both sides of the inner cavity 11 Lift 13, respectively place a conical hoisting iron core 2 with a large diameter at the lower end and a small diameter at the upper end on the two positioning protrusions 23, the hoisting iron core 2 has a cooling hollow 21 with an upper end opening, and the upper end of the hoisting iron core 2 is higher than the ingot There is a through hole 22 at the center of the vertical axis at the position of the upper mouth of the mold, and there is a pit 23 corresponding to the positioning protrusion 13 at the lower end of the hoisting iron core 2 . The alloy ingot mold also includes two cooling funnels 3, the cooling funnel 3 includes a funnel cup 31, below the cup 31 is a cylinder 33 ...

Embodiment 2

[0025] Embodiment 2: a kind of ingot casting method using the alloy ingot mold with cooling device, it comprises the steps:

[0026] (1) Casting: Place two conical hoisting iron cores 2 on the steps 12 on both sides of the inner cavity 11 of the pouring tank 1, and slowly inject the molten alloy into the inner cavity 11 of the casting tank 1;

[0027] (2) Cooling: insert the drain pipes 32 of the two cooling funnels 3 into the cooling hollows 21 of the two hoisting iron cores 2 respectively, inject coolant into the drain cups 31 of the cooling funnels 3, and the coolant flows slowly through the drain pipes 32 The cooling hollow 21 of the hoisting iron core 2 cools the hoisting iron core 2, and the coolant flows out from the upper opening of the hoisting iron core 2 and flows along the cylinder 33 below the leaky cup 3 to the top of the alloy ingot hoisting hole, and the coolant is on the surface of the alloy The upper surface of the diffusion cooling alloy; the ratio of the ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com