Fixed bed slag gasification furnace material distributing temperature controlling device

A slag gasification and temperature control device technology, which is applied in the field of gasifier, can solve the problems of gasifier feed fluctuation and pipeline damage, etc., and achieve the effect of long time in air, increasing time in air, and better effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

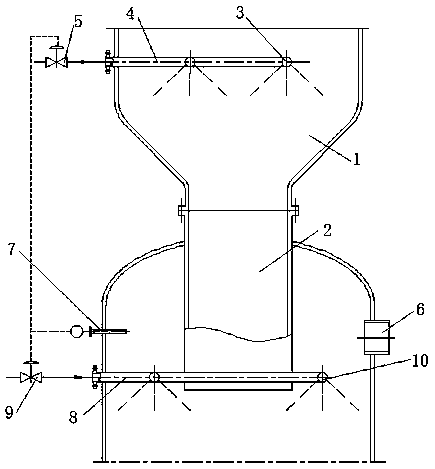

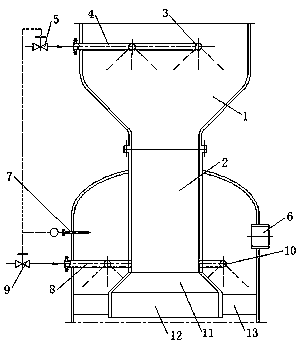

[0022] A material distribution temperature control device for a fixed bed slag gasifier, installed in the gasifier, including a buffer bin 1, the buffer bin 1 is arranged above the feed port 2 of the gasifier, the upper part of the buffer bin 1 is open, and the lower part is connected to the gasifier The feeding port 2 is connected; the upper part of the buffer bin 1 is provided with a feeding nozzle 3, and the feeding nozzle 3 is connected with a fluid raw material feeding pipe 4, and a feeding regulating valve 5 is arranged on the fluid raw material feeding pipe 4.

[0023] Heavy oil and other fluid gasification raw materials enter the upper part of the buffer bin 1 from the raw material feed pipe 4, and are sprayed out through the feed nozzle 3. Raw coal and other carbon-containing substances are added from the upper opening of the buffer bin 1, and the heavy oil, etc. has fluid gasification The raw material is mixed with raw coal and other carbon-containing substances, and ...

Embodiment 2

[0025] A material distribution temperature control device for a fixed bed slag gasifier, installed in the gasifier, including a buffer bin 1, the buffer bin 1 is arranged above the feed port 2 of the gasifier, the upper part of the buffer bin 1 is open, and the lower part is connected to the gasifier The feeding port 2 is connected; the upper part of the buffer bin 1 is provided with a feeding nozzle 3, and the feeding nozzle 3 is connected with a fluid raw material feeding pipe 4, and a feeding regulating valve 5 is arranged on the fluid raw material feeding pipe 4. The product gas outlet 6 of the gasifier is higher than the bottom end of the feed port 2 of the gasifier. The product gas will give each raw material an upward force, increase the dwell time of each raw material, and make the raw material fully react.

[0026]Heavy oil and other fluid gasification raw materials enter the upper part of the buffer bin 1 from the raw material feed pipe 4, and are sprayed out through...

Embodiment 3

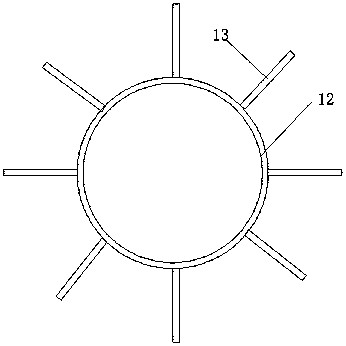

[0028] A material distribution temperature control device for a fixed bed slag gasifier, installed in the gasifier, including a buffer bin 1, the buffer bin 1 is arranged above the feed port 2 of the gasifier, the upper part of the buffer bin 1 is open, and the lower part is connected to the gasifier The feeding port 2 is connected; the upper part of the buffer bin 1 is provided with a feeding nozzle 3, and the feeding nozzle 3 is connected with a fluid raw material feeding pipe 4, and a feeding regulating valve 5 is arranged on the fluid raw material feeding pipe 4. A temperature measuring device 7 is installed in the upper part of the gasification furnace, and a cooling water nozzle 10 is arranged below the product gas outlet 6 in the gasification furnace, and the cooling water nozzle 10 is connected to a cooling water pipe 8, and a cooling water regulating valve is arranged on the cooling water pipe 8 9. The product gas outlet 6 of the gasifier is higher than the bottom end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com